STRESSES INUUCL RICH 17 Slit 13, LOAD APPLItU AT AN INSERT

Suppitinept to

STRESSES INUUCL RICH 17 Slit

13,

1

LOAD APPLItU AT AN INSERT

Scpturiber 1135 itiFORMATI

AND

RV

"41/1

Tilts Report is, One of a Series

Issued in 447Aboperation with the,

ANC-23 PANEL ON CeNSMJCTION\

A-111P If

°

0 11 tli Q U

N art,"

A

184,a-A

UNITED STk PgPAgTMENT'D GRJCULTURE

SERV':

C

T'

S La z

A

, i\,, 0,11 5, W. i t-tto n s i n

In Cooperation' m/1th the University I-oi ,Wisconsin

A 16 R Y

Supplement to

STRESSES INDUCED IN A SANDWICH PANEL

BY LOAD APPLIED AT AN INSERT

1

BY

W. G. YOUNGQUIST, Engineer and

EDWARD W. KUENZI„ Engineer

Forest Products Laboratory,— Forest Service

U. S. Department of Agriculture

OWINIVOIWOOVIIM

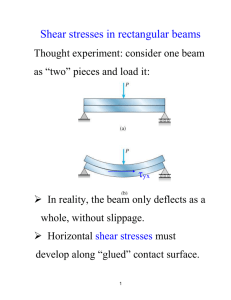

A previous study has indicated that theoretical formulas for the stresses produced in sandwich panels by a loaded insert are satisfactory for use in the design of sandwiches having isotropic solid-type cores. This report presents the results of tests using panels having honeycomb-type cores.

The results show a good correlation between computed and measured values, and indicate that the theoretical formulas for isotropic cores can also be used for the design of load-carrying fittings in panels having orthotropic honeycomb-type cores.

Introduction

This report supplements the previous work dealing with the general problem of the design of load-carrying fittings in sandwich panels reported in

Forest Products Laboratory Report No. 1845. The previous experimental work was limited by the procedures used to tests of circular sandwich panels having isotropic solid-type cores of end-grain balsa or cork board. The present study utilizes a different method for determining shear strains in the sandwich cores, and reports the results of tests of sandwich panels having orthotropic cores of aluminum honeycomb.

1

—This progress report is one of a series prepared and distributed by the U.S.

Forest Products Laboratory under U.S. Navy Bureau of Aeronautics Order No.

NAer 01628 and U.S. Air Force No. AF-18 (600)-102 and DO (33-616) 53-20.

Results here reported are preliminary and may be revised as additional data become available.

2

—Maintained at Madison, Wis., in cooperation with the University of Wisconsin.

Rept. No. 1845-11 Agriculture-Madison

Experimental Procedure

Sandwich panels were fabricated, and shear specimens and circular panels were cut from them for testing. Each circular panel was tested by- loading through an aluminum insert. The differential movement under load of the top and bottom facings at various distances from the edge of the insert was measured by- Tuckerman gages. The method used for correcting these

Tuckerman readings to shear strains as measured on matched shear specimens is outlined in the appendix to this report.

Strains were measured on the facings of some of the panels by- means of

SR- resistance-wire strain gages.

Materials Tested

Nine test panels, as described in table 1, were fabricated for test. The commercial honeycomb-core material consisted of 0.003-inch perforated aluminum foil formed into 1/4-inch cells of hexagonal shape.

The construction of the core material and the orientation of the planes involved in this study are illustrated in figure 1. The facings were of

75ST clad aluminum alloy, and the aluminum inserts used were turned from solid bar stock.

Fabrication of Test Panels

The testpanels were fabricated as 24-inch square specimens as shown in g panel and the shear specimens that were cut from the remaining portion of each panel.

The core material was cut to the required thickness with a handsaw, and the resulting sections were lightly glued together in proper orientation to form mats 24 inches square. A 2-inch diameter solid aluminum insert was careful34. machined to the same thickness as the core and inserted in the center of each mat. One-quarter inch diameter holes in both the insert and the facings permitted accurate alignment of core and facings. The facings were glued to the cores with a formulation of epoxy resins.

The circularpanels and shear specimens were cut to required size with a metal-cutting bandsaw.

To permit the measurement of the differential movement of the upper and lower facings of the panels, holes were drilled at the locations shown in

Rept. No. 1845-A

-2-

figure 2. These holes were 1/4 inch in diameter and penetrated the top facing and core. A concentric 1/16-inch diameter hole was drilled through the bottom facing for a thin bolt which extended above the top facing

(fig. 4).

Method of Test

The method used for testing the panels is illustrated in figure 3. The

20-inch diameter panels were accurately centered over an 18-inch diameter hole in a heavy base of densified laminated wood mounted on the upper platen of a testing machine. In all cases, the test panels were simply supported and not clamped to the base block. A tensile load was transrnitt ,A. to the panel insert through a flexible cable attached to the lower hear' of the testing machine. This method of loading permitted the unreoLricted use of the Tuckerman gages at any point on the upper portion of the panel.

Of major interest in this study is the distribution and magnitude of core shear stresses at various locations in the panel. These stresses can be determined if the shear strains at the points in question can be measured.

In the previous study, these shear strains were measured with SR-4 type gages imbedded in the core. Because of the discontinuous nature of the honeycomb core in the present study, a new method for determining shear strains was necessary. Figure 4 illustrates the method used. The method consists essentially of a means of measuring the differential movement of the top and bottom panel facings at a given point. To accomplish this, a

1/16-inch diameter bolt, extending through the center of the 1/4-inch di., ameter hole in the top facing, was firmly locked in place on the bottom facing, as shown. The movement of this bolt with respect to a, special clip glued in place on the top facing was measured by a Tuekerman optical strain gage. A few trials indicated that the observed movement was proportional, but not equal, to the shear strain. The method used for obtaining adjusted values is'outlined in detail in the appendix to this report.

Simultaneous readings of load and strain in the core at two gage locations were obtained at uniform load increments until a previously determined load, which was well within the elastic limit of the panel, was reached. This procedure was repeated until values had been obtained at all test points

(fig. 3). Strains were measured in the LT and LR directions on all panels, and also in the L 45' direction on one panel of each thickness (figs. 1 and

2).

Facing strains were determined on one panel of each thickness by means of

SR-4 gages of 1/4-inch gage length glued to the top facing. These tests were made prior to drilling the holes in the panel. The gages were glued on at distances of 1-1/4, 1-1/2, 2 0 and 3 inches from the center of the insert. Facing strains were measured in the longitudinal and radial directions, and also at 45°.

Rept. No. 1845-A

The shear tests of the specimens cut from the square panels were made in accordance with the method outlined in ASTM Designation C273-532 and as illustrated in figure 5.

Formulas Used

Two of the formulas presented in Report No. 1845 are used and referred to in this report. They are the formula for the shear stress in the core at radius (r)

-m g (h + c) I -

1) in which

K = 1 r

[ i _ 4-1, a(a - b) and the formula for the facing stress at the edge of the insert

(2) r

Ph vf(h + c) l+ h + c hab

2a

2 a 3(h + c 2

(3) where -r(r) _- shear stress in the core at radius r car -- facing strain at radius r

P __ applied load at insert c -- core thickness h -- total sandwich thickness r radius measured from center of insert a -- outer radius of sandwich plate

ID -- radius of insert

Im ff t h + c 2 h - c fp f l facing thicknesses; equal or unequal

I =

=

+ I f f3 + fi3

12 a

Ecff I f

-- shear modulus of the core, associated with core direction in which stresses are required.

American Society for Testing Materials, 1952 Standards, Part IV.

Rept. No. 1845-A -4-

Presentation of Data

The measurements of shear stresses in the cores of the panels are tabulated in tables 2, 3, and 4. The values in columns 1 to 5 inclusive of tables 2 and 3 were obtained from tests of shear specimens cut from the outer edges of each 24-inch square panel (fig. 1). The values obtained from tests on shear specimens from the panels of 1/2-inch nominal thickness were also used in the computation of values for the 3/4-inch nominal thickness panels

(table 4). Sufficient shear specimens of the required length (9 inches) could not be obtained from the thicker panels. The distance of the center of each gaging hole from the center of, the panel is shown in column 7.

Column 9 shows the indicated movement at each gaging hole as determined by the Tuckerman gages. The shear stress in column 10 was computed on the assumption that the entire indicated movement represented a shear strain.

The values in column 11 were obtained from those in column 10 by the method outlined in the appendix. The values tabulated in column 12 were computed using formula 1, with K given by formula 2. The values of parameter K, from the adjusted test data and as computed by formula 2, are given in columns 1' and 14 respectively. The data in tables 2, 3, and 4 are presented graphically , in figures 6, 7, and 8.

The measured facing strains and the computed facing strains at the edge of the insert for one panel of each thickness are tabulated in table 5 and shown graphically in figure 9.

Results of Tests

The observed and computed values of the parameter K are compared in figures

6, 7, and 8. The curves for the computed values of K in the LT and IR directions for the 1/4- and 1/2-inch nominal thickness panels are based on the average dimensions and properties of three panels of the same nominal thickness. In general, the values obtained in the LT direction are somewhat higher than the values in the LB direction. The observed values are distributed fairly uniformily above and below the computed values, and reach a maximum of about 1 near the edge of the insert. In general, the experimental points show good agreement with the computed curves.

In addition to the data presented, measurements of the relative movement of the two facings in a L 45° direction were obtained on one panel of each thickness. In nearly every instance, the values obtained were intermediate between the values in the LT and LB directions, and therefore were not presented in detail in this report.

Figure

9

shows the observed direct radial strains at various points on the top facings of one panel of each thickness, and the computed strains at the rim of the insert for each panel. For ease of comparison, the strains

Rept. No. 1845-A -5-

are shown at the arbitrarily selected center load of 100 pounds on each panel. The strains show a rapid increase as the rim of the insert is approached. The maximum values obtained at a distance 1/4 inch from the insert are well below the computed value at the actual edge of the insert. As mentioned previously, the measured strains in the LT direction are greater than those in the LR direction, with the strains in the L 45° direction being intermediate. The computed strains are greater in the LR than in the LT direction. No apparent reason for this discrepancy was noted.

As pointed out in Report No. 1845, the designer of a sandwich structure involving load-carrying fittings is interested in the maximum shear and facing stresses involved, and the points at which these stresses occur.

The present study was limited to one type of core material, one panel diameter, and panels of three different thicknesses. However, the data do provide a good correlation between the experimental and computed values.

Conclusions

Report No. 1845 indicated that previously developed formulas for the determination of shear stresses in the core and facing stresses in sandwich panels having load-carrying inserts in solid-type cores are satisfactory for design purposes. The purpose of this supplementary report was to check the validity of these formulas for use in the design of load-carrying inserts in sandwich panels having honeycomb cores. Tests of nine sandwich panels, having aluminum foil honeycomb cores, aluminum faces, and solid aluminum inserts, show a good correlation between observed and calculated values. This further confirmation indicates that the formulas presented are satisfactory for design purposes.

Rept. No. 1845,A

-6-

Appendix

Report No. 1845 (and No. 1828, on which it is based) presents formulas for the determination of shear stresses in the core of a sandwich panel due to a load applied at an insert. To check these formulas experimentally, an accurate method of measuring shear strains (hence stresses) in such a panel under load is required. The experimental work reported in Report 1845 was limited to tests of panels having solid-type cores in which it was possible to read shear strains by means of SR-4 resistance-wire strain gages imbedded in the cores. To extend the experimental work to discontinuous cores of the honeycomb type, a new method of determining shear strains within the panel had to be developed.

The method selected for the measurement of core strains has been illustrated and described in the main body of this report. From a theoretical standpoint, the method is objectionable since it is necessary to drill holes in the panel facings, thus introducing stress concentrations and discontinuities. It was also necessary to disturb the core locally since the 1/4-inch drill penetrated the core to mark the center of the concentric hole in the bottom face. A few preliminary trials showed that the differential movement due to shear indicated by the Tuckerman gages was roughly twice that to be expected at any radial section of the panel. A further investigation of this method was accomplished by running a series of bending tests on rectangular sandwich strips, since the data obtained could be more readily analyzed. Figure 10 shows such a sandwich strip under test, and the diagram in table 6 indicates the placement of the applied loads.

A total of 8 specimens having 0.032-inch thick facings were tested for shearing, 4 in the LT direction and 4 in the LR direction. The specimens were cut from panels which duplicated the construction of the 1/2-inch thick panels as closely as possible. The specimens were 15 inches long and 2 inches wide, with a core thickness of 1/2 inch. The strain measuring techniques used for the circular panels were duplicated as closely as possible. Strain measurements were made on each specimen at a point 1/2 inch in from one reaction,

1/2 inch from one of the load points, at the exact center of the specimen, and at a point halfway between one of the load points and a reaction. These points are labeled 1, 2, 3, and

Thus measurements were made at

4, respectively, in the diagram in table

6.

3 points of equal shear (points 1, 2, and

4) and 1 point of zero shear (point 3). The differential movement of the two facings as indicated by the Tuckerman gages are shown in table

6. Some unexpected differences do occur, but the readings at points 1, 2, and

4 are of essentially the same magnitude. Three of the specimens showed a zero movement at the central section, while the remainder of the specimens indicated a limited movement.

Eight shear specimens were also cut from the test panels and tested as previously described and as illustrated in figure 5. The results of these tests are also listed in table 6.

Rept. No. 1845-A -7-

The adjustment factors for conversion of indicated Tuckerman readings to shear strains were determined in the following manner. The shear stress at any point between the load point and reaction of the sandwich beam

(uaing average dimensions) was found by means of the usual sandwich formula:

7-.

TIT; c) b in which P = total load applied to specimen h = total sandwich thickness c = core thickness b = width of sandwich

In the LT direction, this formula indicated an average shear stress of

46.5 pounds per square inch in a beam carrying a 100 pound load. When the average movement indicated by the Tuckerman gages at points 1, 2, and 4 on all four beams (0.001147 inch per inch) was considered to be entirely due to shear, the indicated shear stress in the beam (using the average modulus of rigidity of the material as determined by the shear tests, 69,675 pounds per square inch) was found to be

79.9 pounds per square inch. Thus a reduction factor of 0.582 is required to reduce this value to the computed value of 46.4 pounds per square inch. Similarly ) the reduction factor in the LR direction was found to be 0.650.

It is believed that the correction factors are adequate for the purpose intended, but a few limited tests were conducted in an attempt to better understand the mechanics of the problem. Shear tests were conducted as illustrated in figure 5, using both a dial gage for indicating movement and a Tuckerman gage reading the movement of a pin extending from facing to facing of the heavy metal plates. They gave identical results, indicating that the two methods are comparable for this type of loading.

Reversal of the unsupported end of the glued-on clips did not change the magnitude of the readings obtained. Readings obtained with the fixed knife edge of the Tuckerman gage resting directly on the facing and the movable knife edge on the projecting pin were almost identical to the readings obtained with the gage supported on the glued-on clip, if the separately measured facing strains adjacent to the pins were taken into account. This indicates that strain readings obtained by supporting the gage on the glued-on clip were not affected by facing strains.

A clip of special design for supporting the Tuckerman gage gave values differing 25 percent from the , average when the clip was reversed in position. This special clip had sharp knife edges on one end that rested in line with the bolt that extended through the bending specimen. The other end of the gage rested on a small steel ball. The average value obtained was about equal to that obtained with the glued-on clip.

If a sandwich beam having relatively thin facings and a non-uniform core

(two materials of high and low rigidity placed alternately along the

Rept. No. 1845-A -8-

length of the beam) is subjected to a bending load, the slope of the facings in sections of uniform shear will be influenced by the underlying core. The facings in the area of core with the low modulus of rigidity will assume a steeper slope than the adjacent sections. The extent that this condition holds true for a honeycomb-core sandwich with thin facings is not known. If this condition were present in a beam of such material, the method used in this study for measuring shear would be expected to indicate shear-strain values that would be too high, since no core material was present at the points of shear measurement. The effective core shear modulus would then be very low at the point of measurement, thus allowing large local strains.

The error in indicated shear strain should decrease with an increase in facing thickness. To check this probability, a few additional tests of beams having facings of different thicknesses were made. The results of these tests are also tabulated in table figure 11. All of the data in table

6, and are shown graphically in

6 were obtained under identical loads and methods of loading, thus making direct comparison possible. The additional beams tested differed only in the thickness of facings used. Figure

11 shows that there is a rather uniform decrease in indicated shear strain as the thickness of facing increases, with the 0.064-inch thick facing giving values almost equal to the theoretical shear at the point of measurement.

The data in table 6 show that the amount of deflection at the center of the span (col. 3) varies with the facing thickness, since all the beams were subjected to the same shear stress. The tests tabulated in table

7 and shown graphically in figure 12 were made to check any possible effect of this variation on the indicated shear measurements. The data in the upper portion of table 7 were obtained using progressively shorter distances between reaction and load point on the same specimen. In each case, the shear was measured at the center point between load point and reaction (location 4 of sketch in table 6). The plotted points in figure

12 indicate that the indicated shear strains remain practically uniform under the varying amount of deflection which occurred. The comparable value for specimens having 0.032-and 0.064-inch facings (from table

6) are also included in table 7 and figure 12 for comparison. The deflections, slopes, and radii of curvature values shown in columns 7, 8, and 9, respectively, were computed from the measured center deflections, and are based on theoretical values at the neutral axis of the beams rather than the actual conditions that may be present at the facings.

In conclusion, it has been shown that the method of measurement used for determining shear strains in the core of a sandwich panel is not an exact method, since the results are influenced by the facing thickness. However, reasonable values can be obtained by proper calibration techniques.

The calibration factors presented in this report apply only to the particular type of material tested and identical methods of test.

Rept. No. 184,,A 1.-27

Table 1. -Description of test panels. Panels were 20 inc es ame er w th a so a uminum insert 2 inches in diameter faces of clad aluminum 0.032 inches thick, and a honeycomb core of 0.003 inch thick foil 1 4inch cell size.

Panel: Average

No. panel

01,9.1,907.

Shear modulus of core

....

•

• Average parameter a

:thickness:LT direction:LR direction:LT direction:LR direction

..... .....

( 2 ) (3)

• (5)

♦ (6)

.....

(4)

. ..........

: Inch P.s.i. P.s.i.

A-1

A-2

Av.

B1

B-2

B-3

Av.

:

• 0.321 75,700 '. 32,630

.322 : 80,030 : 33,900

.325 83,800 : 27,730

: .323 s 79,850 : 31,400

:

21.908 : 13.738

:

.568 : 80,730 : 290820

.567 77,430 32,160

.568 88,130 : 32,980

.568 82,100

•

31 650 : 29.291 : 18.186

C-1

C -3

Av.

.812

.812

.813

.812

♦

29.103

19.562

Rept. No. 1845-A

I rd

‘1/40

\.0 o K1

0 0 o

1w0

4 0

1 0 hdi 1 c.)

.

4 4

..........

I

1

!

I .• .

•• •• • •• •• ••

;

0 rt:1 cd

0 +)

-P cti rd

-f '--.,

-P tC\

....- -

0

•• •• •• •• . •• •• • ••

C.- 010.1.-*If\NNO CO

K\O-1-NHHHNN

\C) H- rrN teN r l CV

I r

.

4

rig r a p o

H00H0to00N-

K1 in

0 M) to

-00toI11K.1

NNHH

• • • • • • • •

. •• •• •• •• •• •• n

0 -- H O n 0 K

ONNO\CTOCT

.

\ CY\ CV

• • • • • • • . • t--,--10K100N-tc\

N- 0 re\ to 0

\0 -*

LC \ tt1

Pe\ al 0.1 H H

••

•• ••

H 0 00 r.r\ H OOc0

010\ N-

• • • • • •

1.11

• • •

•• fie . ••

4

10

.)

•• • ••

I i>,

XI

I d• •• •• •• •• •• •• .

••

• •

••

• •

•• g

I r ci te r--

1 Q) .,'

.----.

I pi

0

'

1I ei 4-I

00 1 0

•• .

(I) I n v. •• • •• •• n •

NCO K\ al N- If\ r-1 0 t.- CO tr1 H.

0 N t-- 0\

.r1 cr) .

0 0 1,4\ co In cr, in N o

\-0 111 4

K1

OJ r-I H H H

PA

• • • 4, •• •• •• •• •• ••

0101 CO 01N N- 111 r-4

N-- 111 H co 0 re tf\ If\

N

0 W N-rn co IncY. ir\N

K\

••

0 r- r- H H

•• ••

N N

•• ••

00 rr\ co to a.

L.) If\ -4' K

.

\ cv r-4 tr\ H 0

--CO H 0 CV N r-i

.

- a\ o t-4

•• 0* •• •• d• ••

7-1 1'

-I-) l

U) 1 Ct3

-

;-.4 i 03

1

1)

4

Xi 1 -4-

Cl.) 4 VI

,

1

1

1 0 i 0 i P

I w p

(i)

I

1

id a)

.r-

Z g rt:i

)

<4

-, (l) I cl) 0

0 H n -

H

H n

• n

P

-

4

.

--1

M.. c--- in

i- --,t s rl th 0\

N-

-

\ ON CN

0 CV 0101

•• . .

•• •• •• ./..... 4.• . •• . •• . ••

•• •• ....-•.. •• •• •• •• •• •• •• ell •• /....,

....••

•• ..••

•,.. -..,

...--..

H

1--si ..,-(

17) r•••

0

va)

.4-i rd

...

-

\.0 0 01 CV K1

-4- H CT n 11

..,--....---....

N -. 00

• 4

-

0\ 00 COO

.

..........--, ....N.", ...--,

H -4

-

CO C-- H i

CO \D CO K1 to

CvN.-1.-.1.

S

01

0 0-0 00 c0 H K\

• • • • • •

Ln

4

. H. ( X ). K .\ C T. C T. t---

A

H

In to K10

-1 H CV o tn..° o n .c.) N

Isr n 0101

CO

• • • • • • •

CO tr

LIN trN

(l1 (N/ r-I heN

CO 1,1 tr.\

Lt1 111-4 H tf1 111 al K1 N- C

0 0001

• • • • 4 • in

If\

4

ON

N- 4-

N

.

-- al al 0

• • cr.\ in if\

N H

0

H H K\ \C) OJ .10 0

N i s

0 K1 rN 0\

0 0 Ls

-

\ 0\ c) 0\ in H tros)

4 4 trN N 11

-

\...t

K1 aj H H

0

CI)

ON ON ‘..0 H N

.--

K1 tiTh K

.

\

In

4• 0, •• •• •• •• . •• .

$1

0 \.0 cC)

(1) OD CO \C:)

\O N- CO H

,-0

• • •

• • • • • •

1

PA

•r,rd l

•11 •• •• •• so ••

PA rd

4

•• •• •• •• •• ••

4-4 CO CO © 0N ,..,0 0 v

+, • • • • • •

N-- 0 4 \D 4 4 a.I

r--I

•• d• ••

*0

• • •

•• •• •• se

.

r d 4,

0) tdpl

U CU

1-4 t, b0 r4 11

H

,--..

......-

..4-4

PI

H

•• .•• •• •• •• • •• •• ••

. N c

14 b

VD

.

o

,1

N

CO N H

H

H CO H .-1- -4-

H 0 i.-1

OD H H c0 --1- N

0 01

01 0 4 Lf 1 MD H toK1 0

H00000 F1 NNHHHH

,

0N n ..0

0 0

N al al 0-4 toco H H --1-

01 CC) 4 -4 al c). N to N- In i00K\

0 0 0 •r-i 0 0 0 0 0 0 0 0 0 •ri 0 0 0 0 0 0 000

0 0 0 0 0 0 0 0

.14 •• •• •• •• •• •• •• •• rti a) t____ .() co 1.

I 0 0

_1.

0 0 0 0 0 0 0 0 0

• 0 • • • •

•• •• •• •• •• •• •• •• u•

N

0 VD

PI H H 0 H 0 0 ft, a)

• • • • • •

..• •

•• •• •• •• •• •• •• ••

•• ed

(I) rti cd

H t-4 C14 cd l l

4

'1 8 fil re-I

O ;-, H

0 g

-

1 1-1 FA (1)

0

V) al d

(1)

,-.1 14) 0

( 1p i

.1), g

Pi

64 •• •

......., rd cii 0

4) -4

........

. •• ••

...-to

.91

P4

0)

00 ;.-, a) +) Lr\Otr\000000 4-, o

PI •

H

1 ai

.

a)

/El r1 H r-I r.--I H r-1 r-1 r--1 r--.1 11 H H r-i H 4

114 . . •• •• •• ••

•• ••

CO CV rt.'

H

0 0 0 0 0 0

00

0 0 it) C) 0 0 0 0 0 0 0 0

.4 -4-4 -4 -4 -4-1- -.I- ra

$1

•-I

CI

1-1

•• •• •• nn • •• •• •• .

•• u-Nt--0(Docp oo co cunt r1 r-i r4 C .

1 n e --1.

ts-\ n .o

•

N--

........

H

I

H

-

.

--4 r--1 H 4---I

0 • • • r-I

N

I

-

CO a) 0 0 a) -4 -4 4.4 -4 4 iEj

F.-, r,.-1 H

0 0 0 0 0 0 0 f• •• •• ••

•• •• •• ••

••

-, 1110L(1000 000

00000o co cvu\c---000

........,

N

<14 r4 ,--1 .--;

0 0 0 c v. rc \* _

-

1.. t r \ . 0' N -

9

•• •• •• •• de • CO • es. H

(A

•• •

•f• •• •• ••

011 •• •• H a)

•• silo •• .• •• •. •• •• •• H a)

•• •• •• •• II. •• 0• •• ••

0

0 cd :24 H CV re n ...4 Lc\ N-CO o n

p_. g

H Ntr\ -4- t11\0N-co c)\ g

H CV K\ -- tr n \c) t`-000.

•• •• •• •• •. .• •• •• •• • •• ••

••• .• •• CO •• •• . •• •• •• •• •• •• •• •• •• •• el• so a) to r

H

O

0 o c

42

H........

fA TS tt)

'..

•r-1

••

PI

•• 04 ••

•• 1•41

• •• . ••

•,-.11

ca -..,.-1- tn NC.,-

P.,

•

0 0 0 0 to

000 0

0 0 0 K1

CO N- VD

... .... .4, __1- h h h

N-00 N- N-

N K1 H CV t(1 tr n rrl K.\

•• •• •• •• •• •• •• •• e•

00 •• •• •Il •• el •• •• ••

PA of

Md ..1-1

O a)

Pi

4

Cf) d

F-1

-P

10

.-.. •r-i

. . . . . .

4* '‘..

......,

P

H

• 44 SO .

• K\ N- K1 H teN 0\ K1 al

N ri N N

000

0

0 0 0

0 0 0

0

. . . 40 . . 4. da •• • co v) Ntr.

L(1 4 MD Ito

NNN

CV

000 0

•

• •

•• ••

•• ••

,s1 a) 1)

03

;-4 (0 cad iti

....-/

-r-i

------. n 9 al 4 4K1 oD

•

N.

°

J.

0 r'')

00 CO

1 al

47.)

•• .• ••• r.c a)

-i - , rd ,-I al

Q) 0 P4

H 1-1

P4 al

..----- r

10 id

N 9

0

0 • to

.

a)0

Pi

..--..

IH

....-...

.0 .0 .0 r-i r-1 H

.0

H

.• •• .• •• •• •• •• •• ••

000

0 0 0

0 0 0 h h h

N N N

•• •• •• •• •• •• •• e• ••

H N K\

H H H

<4 <4 <4 H t>

• • •

•• 00 •• •• •• •• •• ••

0

00

0 0

0 0 0 h h h p-- H .--I

•• .10 •• •• •• •• •• •• •• r-i

Pc)

1

Y

C

CV K i

-) P

.

\

:

1

H r-i

H

1

1> <4 c--. .-- -4 so •• . . •• . •• •• • •

000 0

0 0 0 l'eN

,

CO te\ 0

K\ LC\ H 0

ON CO \ID CO

•• •• •• •• •• •• •• 4,6

••

N-0\ t H

HHN N

000 0

• • •

•• •• •• •• •• •• ••

-4 4 n

.C) \.

:) N-

H

C\-1

\..0 \.0

0 r--4 1--1

N-

\I)

\...0

H

•• •• •• •• •• •• •• •• ••

000

0 0

000

••• ,

NNN

•• •• •• •• •• •• •• •• ••

H al K1 s

<4 <4 al

C\J 0.1 i k>

<4 <4 <T4, H

C‘l

0

H

..,4

I in

-4-

CO

H

0

I

a)

-, rz s

Pi

tU

•C) ro a)

•

0

00 011 •0 0• 4

044 rt

1

(1)

▪

1111

• fa •• .44

•• t--\..onntr\NNHH

• • • • • • • •

0

•

•0 0• 0• •• 40 Ile a0 to lfl

•• ••

K

N o

. Se n Dt-Hom-Noor..-

0ocr-0rc)no n o.4

• • • t o K1

• • • • • •

• •• so so a• ••

NntrNNN-0.-tpcNN

COncONteN4peNNN

• • • • • • • • ell Os •• do

06 ee

Ill Ill t

4.3

i2r1) to tri

(1)

4-,

•ri

0.)

• 9

••

41111 rte to cd tU ttl rd g ntj aa

..

4-7

• •• So ••

••• • r4

14.

CI)

••••••,

•I 0

•• .0 Ir• de •

01 rtj mmoopc n Nr-nHo

• • • • •

-'°.*° K

°NHHH H

NAMKNNI"....nHO

C.-Wnr4.40NM

•.

0

• • •• • • •

0 KV:0 In

ON

N 0

•

14.1 N H

H

.6 Oil •• Ill IS a.

• . f• al 0

.

• 41•1 011 . n

......--..........

DOOnMHNOV004

•

...,.....w..-.., riMnH-It`..MMN

0NHk0te1NCON10M

•

••

•

• •

/411n4 n

• 4 • •

••

• • • • •

OHN L"... altr1t.-..000

• n 04\014NK n Nrir-i

,..............

••

46 all

46 60 ell ell 04 •• de •• n re n k.0 n WQFJH n u"‘ c0 \O

D-1"ntsm

• r-m

• n o

• n

• • 4 • • omv.).omH

• rl

PCI

Os IS 04 • ► •• om n DnN4.4m00

H...1-tr n c-n000

• • r-1 H

• • 4 • •

CO N ON OD

1

,

4"N H

•

..."11

116 06

•• 04 Gs

60

•

. di •• Ike •• 410

OrND

HHOCOC.....

mr) C-- N CC) CO .4

0\10-40C-LFIN1 ontnno.

000000000

• • • • • • • • •

CZDH000000

000000000

• • • • • • •

04, 66

00 64

•• 11 66 el 114 to o

000000000

,41-Ar-41-11-4,-1HrArl

40 to

444444444

HrAr-irirAr4HHH

• a. do •• 40

011 00 00

RRP888888

• • • • • .

H

HHNK\Lt"\ n o

• • t20 o ee •• •

H te\ e• •• ••

H

0

C-CO 01 PA se 0• ell .11 66 OS No es •• So to

•6 di• •6 46

0000

000 0

ON

In

114

H pc•N re\

trN K1 t.C.1

trN

.

d• 06 Ile . . 441 es 06 . Is p4) tO

Os •• 410

H sie •• 40 •• reNnoi n

000 0

000 0

• • •

0

44 e• 60 de. •• •• gd

LD

41;.4

4/) fa r1 •• •, •• rti

1;1-I

I te\ U).

•• 04

IN

5 a: "

141

14.1

1

.

C1 1.(1

COCOM CO de 40

0 0 0

0 0 0

000

•• •• •• de ,11111

• • as Se •• •• 06 •• •• e• Os .

•

RQ

H

RR P888882

• • • • •

•• 1111

N K14 111\13 t

...

00 O.

so 60 •• lie so 44,

0

000 0

CO OD CO CO

011

CO

•• •• •• 06 •• 06 f• .

110

N

-4

.

ON CN

H ON r-i

ON

H 1.-4 N H

000 0

.

• •

•• •• 414 •• n

.0 r-I H H

\C)

40 el 114 -Ill 114 e•

•• 66

0 0 0

000

•• n h

NNN

1.• 1111 11111

•• 00 •• 110 116

H N

K1 tc

I n

.4 <4

Pc\ lc\

<4 .4 <4 e t•

-4

40 cr) RRP888888

• • • •

• 611 60 ••

••• se ell •• lis

H N LC\ 0 t.--00

O\

•• 110 le 1111 1111 1. 60

1114

000 0

0 0 0

N 0 0

116

N N N e• Ill/ .

•• ell •• se so

.•

\O ,I 0

C--

CV r-i

N

NtrNt41 prN

000 0

0 0 0 0

• • • •

• 40 •• 116 64 es s• 66 t e

N

K1 to

K1 reNteNK1 1.4-N cc) cc) 00 CC) oil 0• de Ile •• GO o o

000

,4-iftr.4%

•• a• •• sit li• •• •• •• ••

,7MR tc1 t<1 t<1

<4 <4 .4 H

1-4,..OHOMOeThte1

c-A.oninfe

n NN--1,4

• • • • • 4 • • •

40 Oil da lio

COC-...

n OteNNOOt`..

rrfn trENI -q

0

. •6 t• se de 11 0• ovoNmre\Nt-Ine-lo ozi te n cti ct n tr\s 40 ft • 11 •4 O.

RN

•

0?-1,1 n 0"-N00

,-1,-4vonn.4

n 0m

• • • • • • • •

V4APJ°111.te,

""....".

R22-5gRcgf.-1

• • • • • • • 4 •

VERFAE,tilP re Se do •• •0 •4

••

0cONHC-,1n4

00NNN4r.c

n Nm

H-tc040\40 n 04.8

NNHHHOOo

000000000

000000000

• • • • • • • • • •

46 46 as • 00 as ••

000000000

•

•

• •

11

44 46 811

rC-1

CU

I

Ni

0 td

0 tfl

4-1

0

2

P4 0

4-1

0\\0t-orrNin0m3-1-

C.--\.onnt,nNNHH

• • • • • • •

O

• • •• • • or-HowNoot-M t--\.onntrNNNHH

• • • • • • 4 • •

•• •• •• •• do •• •• • •

• •

.•

• •

• •

OONC-NHH oNainHnrcN0-1.

N.-N-00.4.K1NNNH

• • • • • •

•

•

• •

U)

01-1

0 co

4-,

U)

E-1

•• •• •• •• 141 40 •• •• fir •• •• do g o do •• •• •• ro d

..421

1

Fl 4--1 P.,

0

M 0

(7) .• •., •• • ••

4• • so tn.

N --/' 0 n 0 C-- re\ 01N-

....1-nMvpt-cOma)....1.

• • • • • II • • t-mrsnmm....tHm00

•

....*K-NrcNNHHH

0 \O /4"1 N-

\soMKNMm-4-Hm00

0\0 MCNN-

-11.1101\.0 CO WI CO

••••••••• t-m-mm...1-Hmc0

-.1.rerNHHH

•• 4• •• •• •• f•

•• •• 0•

4.

06 •• 00

•• 011 ••• 49 •• de ••

.

•

;

Xi rfl

1-

0

4 .

.

4 E .

4 r d d -po d

P

P.,

.

r a) ci a

<4

u •

9 " •

U) )

H

H H

•.

P-L

•

-1

•

•-1 t---000n_4-om0000

\so...4-nm\porNtr

-* H00\0 reN \.0H

.........--..--..................... n.4-.....tmt-

H o

CO

Ht<1

•

O

•

N-N

• •

MO1

N 1 \r) H\0

.4r\NNHHH.----

...........-........-----..... p

•

CO\ON

00

• •

-1\.0

• •

\00c0 in

\ono n

0

0 cONONHK-NNONC---.4-

\D

• •

.c

O'N

• g

•

WI (::2 1

•

CC)

• •

H

•

-A P

...-1 vp....1.H0v)....1-\0mo

0 0 Hp8..\14HRrekn: e.

•

• • 4• •• • • r

H ....-,

•

P-4

•

•

0

4.,

(1)

••-i rd

• ••

0\

00•••••••

0 01

H

'

• ••

N-

••-

C)--.1li

•ri cONHcov

4.,

-I- N H H CD

$.4

-1-1

4,6

E•

.• •• de . ••

• n

O. •• •• •• •• 4• •• •• SO

O\to00'000 aD H NI.C1

•••••••••

C) tr1-1- '41 Nair-1H

SO to

•• ••

••

•• •• ••

14

4., a)

$-1

-1-1 rd

•

•

• •• •• •• •• •• NO de

CV 0 N- N- N- N- ON H N

•

40 ••

• • •

44 00

• • •

IL

,Q

•

If/ ••

•• Oft •• •• di!

4.,

0 ti5

ZJO

,-„, m eil

'!d

P

1

••

••

•• 4• .••• •••• •• ••

ID

000nmt-\pmW\D N .cpWHoHH0\00

C--- In 00 N \0 O\ -11.CNO

N H CO CO LC\ --1-1r1N N

•R HHO00000o „1

000000000

000000000

•• •• so 0• •• ••

••

N- H CO 0 naDt-nmM\00.4.

Mon-ttr\reNNH

NHHH00000 H 00HO00000

000000000

000000000

•• .•

441 ••

Os ••

•• . •• tel cu

000000000

000000000

• • • • 0 • •

SO

♦• •• 114 •• •• •• ••

WO

1 3 ;1

H R d

ta Cr)

0%3. 21

S d• if 44 . d• 4. . 46 •

12

9:

4

0

0 0 0 0 0 0 0 0 0 0

414 . •• •• •• •• Se 41. 46

000000000 d 000000000

Q 000000000 M 000000000

0 NNNNNNNNN 0 NNNNNNNNN 0 NNNNNNNNN

•• 110 . . •• 46 •• 44 614

2

.... .... .• .. •. .. ..

.

00

4 H

•

43 tIng

9-1t100

•• ••

♦ d a)

WO ►

0

0) d

;-.

L

.--'

• •• de 0•

4 m Nnt-000000 0) Nnt-000000 m Nnt-000000

0

0

H

• de

H

P:1

1

4 0 • r-slr-slr4a1 M

-4

LC\ ‘.0

H •• .

• •

.---1,--1r-lN rcn -4- LAC; L- •----

.---1

1

Pt)

•• rt• r• a. r.

••

H

44 •• •• •• 4•

•• •• a)

Pa

1 rl a)

H

6 • • • • • • • •

HN K1-1

In n .0 C--

•• •• •• •• •• •• •• •• ••

........

\C)

.....0.

8

P-4 H al re\--111.1‘.0 N-CO 01 g

Pa H al K1.4 in \.0

N-CO ON g

PA

H CV K"N

-

I L.C1

n

.0 N-CO ON

•• d• •• . 4. •• . de •• as 4 . •• 40 . 00 •• . 44 •• . . de . di . 40 16 00

O. .

•• .

••

•• d• o

•r.1

F.4

•• d• •• •• •• 40 •

.•••••• • n mh h h

•

0 0 0 0

000

\DC-m

H C .

-- CV

0

\C,

01 CO CO

••

00 f• •• . •• le 410 di

•

H 0

C.

H

000

H

0

00

0 0

• • • •

0

•• •• •• •• •• 00 ••

• 0 vs 40 •• •• 40

0OWN N

0 OJ N CO

• t

0 ONO 01 c n N K1 N

•• is do

4,6 041 44 00 trN trN

1•C1K1 rt1

K1 tr1

/.(1

000 0

000 0

• • •

000 t--a,

N- P2 N-

4111 44 40 •• •• 44 ••

Lf10I

NN Cap

000 o

• • •

••

00 ec1P-L

4.)

•• '16

N

•• •• •• •

1.94

cU

•• •• •• •• •• ••

• tr‘

.r1

0) \D

\O

\.0 \D

•

H

\O

44 •• 66 s•

000

000

NNN

•• •• •• •• •• •• •• •• ••

•= 4 •*4

HHH

MMM <4

•• 04 04 441 •• 00 •• 00

I• occDo m

• •

OON 0 0 n

•• 46

••

•• •• •• ••

••

000

000

N N

H H

00 110 •• . ••

MMM

1

H H

O•

•• Olt GO •• 414

H 0 N

CC •

%0 n .0k.0

H

••

••

000

000

N N

•• 011 •• •• ••

H N K1

•• ••

1,1

•••-•

IN4

E14-;

0

*• a)

4-2

4.3

-P

Piro CO

• •• •• 0• t

--i

•• ••

••

••

114 ••

00 •• •• Oe •• •• se

0 0

•

Li nn tr1n0 N

000

K1 c0

• • • • • •

•

O

• s• 06 46 •• 04 60

•• 60 •• s• IA* 06 . 00 00 n op r-l n paNt,romaN

0\- N-\).1' rf1 K1 H

H

• • • • • • , • •

60 Oil 00 40

00 •• ea 44 46 . 64 •• •• n

NmocnnooOrc n c:,-..tN0c0HH..4. 0

1 • •

►

•

• • • es le 010 ,•• 414 de rt8

04 44

.11

9

P-4 ao do as . ••

44

4-) 0

I

O 0) frl

0

CT

06 . . SI SO rtj

•

40 40 to

0

. so . foie

.0 o• .

C n !

41-4

04.4

0 0 a)

P4

H

C.)4-41-I cu pl a) q

O -P cu

CO

1

0

L'-. ..C1

.........

4-2WOra4

GO

0,3 ,-4W

A

0 t.)

•• SO •• • ► 106

H

V, a) •

P rd

40 410

0

•• 116 •• 16 46 •• VS

•• •

133 ;,..

O 4-)

H sr-f

'd

:a

0 4p

It oe. ','",

7.-4

•• Oe SO •• 60 •

.

I -.•r:

11n

....... 9

•

P-4

••• MG ••

03

14

Lu

.

R

CO

Cg • ,9

0 al

co4

.

0• •• so so so

-

-

4

•o s• oss r4

9

U)

4-1

0

SO co

•

00

0

04 46 60 •• 00

I

I nzI

I 0

10 .---... ..,-; CC/

4-,

U1 cd 0 li i

"gg

%."'

P -4

4-

,

I

CO I

.:4

O i •• .. .•

I.

• to

•

.

-N.4.

00

• in

•

0 C) N ;.(1

ON n .

\

0 V-- CO U.) 00 .4

• AI • • • • •

\O

-1

ON

K1

KN

ONCT.*H

KNN HH

0100

• • •

.*tc\WNNHHH

• •

C---MKNONMHO1C0

•

00 SO OS •• •• 66 Se •0 11 •• 6• .

---------

P.8 E

OW\000\D....*NN

C 38

04611044441 rrNt.e

n NrrNHHH,--.._.

.

•000414111410

► t-MHO n p000 es

11. so

Om

46 06 46 46 os so

H

N- t.)

40 06

.4N0000000CY

cOnq n CcON-4.NmN

HHHH00000

000000000

000000000

• • • 0

44 06 Ili 06 le OS .

MI

04 44 46 04 116 06

0J(DMOM-.1. ...1 0 mnt,-n o4....41,1

4.)

MoNm4oncoco 0

0

F-4 oo

•• 60 06 moOt.-mnnt-C-l n nwt-n44N0.1

0000u000

000000000

64 do 00 SO

000000000

NNNNNNNNN

66 00 Os SO 60

RRP888888

HI HI

.4 c‘l ;AO

000000000 W

000000o00 o

NNNNNNNNN M

•• •6 00 00 44 fe

03 non000000

(\int-000000 m

• t-; n

64 SO •• Se oe ••

ON CO t"-- n .0 n K1 t*--

NncON N C .- H

••••••••• mNo4 n 0NNc0 n 0

44 46

411 so 46 nreNMK)ONNKNMK"N

4- K\ N \D

•••••••••

00t-t-nmONK q)n...tw

NHHH n M

00 •• . II 0$ Ea 06 Of p4100NnOm tc n N4KvicoMc00,44.

HHHH00000

000000000

• •

• • • 1

• • •

00 6. 64

.

64 •• 06 06

000000000

NNNNNNNNN

•• •6 •• •• •• •• •

Nnt-000000 r4,4,4ckle..44

06 •• •• •• le 60

••

H oJ tr-N n O t---c0

410 . . •• us

000 o n 111 CO \O trN -4` os, •• n es

H

M11"\

K n reN al

N

IN r-rN

016 00 04 06 •11 04 445 ••

••

00pcNK-N

ON CO n .0 n ain rc n

000 o

000 0

0

•• a• too so oo

ON 0 0\ CT i

ON 0 ON

H

ON

CT

••

VS 116 041 •• SO 60

••

000

000

NNN

444

4011 •• •• •• •• IPS p-4N141

I I I

•• •• GO

00 Se So 44 06 00 le

N K14 n n .o N-00 CT P.,

Os di 06 66 46 04 66 04

000 0

000 pc n t---oH H

•• •• a's IN

887a 09

66 •• •• •• O• . . es 00 n

N o0NH m

HHN H

000 0

000 0

•• 41., 04 •• •• •• ••

•• 66

Lrn tr n O n

\O t--- CO n n

K.

t---

.0

H H ,--I H

•• 46 •• •• ••

••

64 $6

000

000

000

N NO4

•• r-i ll• •11 tr n

•• • •• •• tr1 te\ teN

4rc', ON C.-

04 66 •• 06 04 es se

\ n t- c0

66 46 06 •• n

000 0

0f4n 0 00 t-ON M

• n

.. tc n

.1',

.1

Oc0.4. N

Nr,r)

•• •• es •• tc n g o •• •• oe ••

N \ID

N hc n tf

C

.-- in CT n CD

0

60 Os IS •• 66 es •• ot-n H

44

0 . M0 0

H H es so

000

000

N N

44

00 ••

00 06 •• as ••

00 Os

06 •• mmg1

I I

I

KNK n reN et-t

0

N

43

0

0

A

ot--Ho00 o col.c'onrcNNNHH

•

0t-orc

• •

• • n 11

• n 0

• n

0-1

4 •

• •• •• d• •• 411 •• ••

LC1VC) -4- 0 c0 rr\ N- 0 c PP

• • • I

•

• • •

•• de • • 00 •• •• •• n spc---Horroot-n cX\‘,0C-onno\.0.4t---‘sOnntc\NNHH

•

• • •

• • • •

4111 11, 11111 1111 •• 1. 40

NONH nn-4.NNHHH

• • • • • • •

110 40 •• 1111 •• •• •• 60 •• ot---HOK\00t-tr o DN-onn0\43.4

n co n onnw\NNHH

• •

• • 4

•

•

•• •• •• 14 •• 10

CU 11Th C0

0 tr n co

4 10Th tr

01

•

101 0 CO 1012 n tr1 0\ 10Th .4- 10Th CU H

• • • • • •

•

011 •• 1111 11141 114 trN00\O0\0\0_10.4

int-Mnrc n

NNt.--

00

0-4-00 10Th

01C-01nte\10\NNC---

• • • • • • • • coo-toonNoco

•

H (Y-\O 0\ ON 0 4 - 0 -4

01N 01 11Th Pc1 hc1 N N C--

• •

Wo.400nN000

H

(1) e• •• 611 I •

• •

CC)

• •

0\ CU c0

•

-4- N1

• • • •

N- ON

A

.•

•11 66 •• •• OS ••

•• f• 111. •• •• fo•

\

40,606460

0

0

0 N

••••••••• n

11Th

O re\ o H -4- oW n o0 a) c0 t-- 101-4 n

.4- -1. tTh

N-

0

....*tr n reNn

. rc1 04 H H

• • • • de de 64 so •• ••

0

• .

$.4

•H rd re\

4

L(10 0\-4- Cu 00

0 K\0.1 4€0 0 C\la.)0

H o.co c:)

C‘J

0 0 0 0 o 0 0 0

000000'000

000000000

0

•• •• e• •• 40 .0 •11

0 rti al

•1 g o •• •• •• is rd

0)

..-1

H

I sz:0 to rid

000000000

000000000

10c1 rC 101 10Th 10r1 10r1 10r1 10Th 10r1 d3 d o

P.4

O to to

0)

4-4 o d

00 . •• Oil 06 00 11

(1-4

0 Fl tH

00

0 F-4

011,I-4o

-1-

, ta0 0

H

0)05 a) 4,

R ca

4,

.6,.(!))

A

•. it •• 014, •• 40 • to

0)

C r i

. •

-

•• • a) • tbQO .........

M'O

I

...........

0

P,

•• to

(1)

.

••

1

•• 46 •

. •• •• •• le 411 •

Ito k

1041 •• OS a) ai

4-1 rt:3 rdo,A

10

;244 tID

•H

•• •s •• •• •• •• • g• o•

(13

CO

0

•• .• •• nOn000000

NII1C-000000

C n 1 tr)

11Th' C) Nn

• •• de 1,11

11• ••

H 0.1 rc de de

•• •• ••

•• ••

•• •

0

0

0

H a)

11Th \0D

N-CO 0\ 13-4

••

•• .• •• .

•• 40

03

P

M

•• •• •• •• 164

CO

1111 H co o cd •r-i

0)015

M-P co

1110 ••

_4-

I

4-4

0 to

4-) co

•• 1114 •• •• • •• • 110

P d

CO

0)0)

4 w

•H: -

$.4

......, m+, p,

• to

,---...

teN

...,00.4.0.

H rtj

0 o

••

1)0 . d• . •• 110 •• ••

0\

'_

\C.

H

.........

0

1-1fal al

• • • •

40 1111 •• •• • •• •

P.4

•• •• •• •• •• •• de de 11111 ••

1111 •• •• Se

•• ••

011 1111

\D\DCOHn

H n o-Imnomon

• • • • • • • • • trl 101 (3\ 101 0 N- H CTh0

H Cu 10-N-4- n n o N-CO ON P-4

•• 4/0 1. •• 6.11

III 4111 411 64 ••

•• 410

0

10Th n

0

,

H

10Th

1111 o\

H

K\

0 o

•• •• •• de

1111 •• se •• o o o

H

.........

0

•• 1111 •• •• •• •• •• ••

00 60 111/

•• 40

It ••

O

N- C n

1 01‘.0 N- LC\ N

H 0\ -4- C\ 0

H

111.0 10Th

• • • • • • • • intrNOWC-0-1C-H

•

LC\K-1\-OHNNH.....,H

1111 ••

Os •• •• d• a• •• •• •• •• •• i•

CC) r

-

I t-- rev:0 n

Lf1-4-

0 tr n

-1.

Q t--

01;) 0

0

4-1

4.)

C\J cc) r .

LC1

(cc)

LC1 tr\

4 .4

ON t--

4.,

HHn\oH n oop tcNo 0 .4-nrr\m nin--1. KNNHHH 0 n 11Th010rv-1-NHH

•• 011 •• •• •• •• W•

411

N n onomrcNcoco

Hte\tcl\OONCON"\H

0_4-H00)10Th410Th

HHHHH0000

000000000

000000000

• • • • • • • • • d• d• •• •or •• 1111

•• 011 •• 1111 Oa 1111 •• de nHn\oC--InoH

Lr n

HvoN0\0.-1'

Ht----N10N10Th410\HN

HOH00011000

0000'00000

000000000

• • • •

• • • • •

1111 W• 114/ ••

•• ••

000000000

000000000

101 hr1 hr1 Nr110Th 10Th 10Th

•• 611 •• 06 •• 00 d o

El

000000000

000000000

10Th 10Th 10Th 10Th 10Th 10Th 10N

1,rN 10Th

111/ el If •• •• 60 •• 1111

11Th0000000

Nnt-o00000

• • • • • • d

H H H Cu tr\ 11-\\D N-

611

P-4

CO

C\1

0

R

11Th010Th000000

,..4,40,11164106

H

I-

411 al

•11 411 1111 •• 66

•• 4•11 06

If\ \.0 CIN is d•

06 00 d• •• 1. 04 go •• . •• o o

He,

CV

CO

•• co

0

N

0 o

•• •• 110 110 •• •• •11 Of

CY\

VD

\ID

H

•• •• ••

0

0

•• •• 1111

0

0 to

4)

0

0 to to

0

4-)

0 to re\

0 t.i

U

•• 4110

H

•• se

\O t

,

•

-n onnNNHH

•

H 0n 00

0\v0t-01

• •

,

(

• n n0

• • n 0...1

• 0 if .

.

01 nHNCINC\WoMN

.

-00 mo-l p

(NHHHH

• • 4 6 0 • • • • 0

Se 06 06 os 46 *I ee

0C-H0rr\00C-

0 ‘.0C.-0rrNn0 w

• 4 • • 0 • 6 6

66

66 46 4.

04 60 SO n 0-1.0n

......99.:

4. Se •• Of 66 00

‘40C-HOre n 00C-tr n

C.--0nnw\NN,1H

••••••••• re

40 se eo 06 40 04 ee

HN-1.HNHoluno

.........

416 110

SO 441

4141 a)

• .

tO

1 Coi

1 1

?,

r

414 Se OS oe 4111 k al I 4-) 0

-Plq0.

,---..

G) rci g P-4

+' 1

4)

4-1

06 SO et 4111

4 o

-

1 gl

.......

0

.....4

I

Hto I

.......

4-) to

.

13.4

I

4) . . if 4,4 ..

10 44 Is . .

•

•ri 1 to

P-4

+, 0)

• a5 LI t) 0

...-.

CT\ ri P .

.........

1:10

M 9 .

to so 4. as . .

00 64 416 Ire tj tO ng.;1

0 sr, rti to

••

410 fa #6 44 Is 410 tOt

81"1

4-

3

to24

03 0 0

,-14100

9

SO 04 so 44 '414

4) • ta0 al 14 to t)

III

1/411 St •• ••

40 fo f• se •• OS • al

4k to

40 40 4111

•• 44 Il• IS es

4) 4) to as a)

410 00 •• r(1 to

P,

1141 6$

.

00 ao to

0 P4

OP4 is fo le 46 •• se

•

0'

0)0

P4 14

.

ncOCYN0 n 0.40.4.

tr\C-mn\0 Nt--

•••• • 6 •• a00400nNOW

4...*KNKNNHHH ee 46 40 se le .

---------

1-Vi=dR v

0

• • 6 • 0 • • •

ONOK n NC-MaNk.O

n 0

4

HONmON0-1-04

0N-mnK n NNt.--

• • • • 4 • •

04 48 14 06 so

VDnONC.--nt,--..4

6 • 0 4 6 • • •

Ht--reNHMonNM

• re*NO*NON0404nNmnpeNNNC--

• • 4 • • • 6 I

(:)-.1.00nNOM

•

...i4wNHHH

06 .

se de 06

MHMKca).4.H.0

KOOnt.r1telHOWD

SO 441 It Oa

0 n

0 n on..4

.

Nn0M u

0.4p(1NriHH

60 06 di SO le t--0

.

n 0 Mallo4N cYNH PuP44tc

.

000000000 .P

000000000

6.6,46640 pg o

44 OS

Ile 00 el tl

000000000 0 r41nrronni

4

1 0

44

Oa 00 If OS e• Of

44 06

Se Os OS 04

;0o.lwa

, gm 49

I • • • • • 4 • • i t*

A

*

c

F-

4

4"'?) of 40 oe 06 41 46 40

0Hre n c0HreoN-c0 rid

000000000

4 ttl a) is 46 Of 06 00 40 Os 06

00...0000.

tir n 14.\ K1 rr) K1 K1 K1 0

1 le of Se SO at 00

P4

RRP888888

00 40 441 de 410 1114 00 nc9',Elen1HP— k il

• • • • • • • • • q)4-KW\NNHHH

40 of of 60 66 46

40 n ow...1NrrNnH

re\t-Ht-n4r

N.-1HHoo0 o

000000000

000000000

4 0 0 4 6 4 •

40 4141

•• 410 ef

41,

SO

000000000

000000000 tc\t<11(W n tc\t(1<\

06 4141 60 410 fe

04 06 60 110

00000 RRPS

0 0 0 0 0 e

4,4,4 (NI N1-1- tS1\0 t*-- K1 t.)

H 44 ot so so so so

RRP888888

4 01

•

H

6 A c

; as do ea 66 of oe 04 de

Hal,,,..4.n.0t—c00.

H CV N14- it-'-O CO ON

H 141-1. N

-

00 C n die s•

Ili

. 40 eo do so fa se 44 es ee eo fa do io 416

••

64 06

0

LC\

\O r.-.1'

K1

••

0

0

H

.,

CV

CO

Gs •• . 00 se 04 se 00 fa 410

0

\D

H.‘ teN vs

.

ONO'N

H rc\

0

(8

04

0

0

H

K1

0

0

0 es •• so 041

00 04 as SO se no fa OS 410 40 40 se se 041

ON o

0

0

H

\O

'0

H s• 06 OS

So 60 4. so

046

4. 04 46 00

•• so SO •• 00 SO es e• 1141

0

11,

00

110 40 Ise 66 OS 010 00 se

641 IS •• 00 4141 4441 46 ea 44 66

0

CV cf2

Table --Distribution of facin strains of sandwich Emels at an applied cent.22:12211_221:12022E42 tl

I

•

•

Orientation: Computed of strain :facing

Measured radial facing gage with : at edge of : r 1.25"

• respect to insert : ribbon- : r 1" direction : of core :

•

• r 1.50" r = 2.00" : r = 3.00"

•

• strains at

•

•

•

(1) smalopc.s,emovollomomwewskdellor • .ONO

(2)

(3)

...... 80.4M41,:.V.WW ..... OWAIMIWOM

(4)

.......

•

(5)

:

(6)

..... -

• I : I

LT

45°

LE :

Panel A-3 (Average thickness = 0.261 inch

: 0.000530

:..............:

.000180

.000652

: 0.000194 : 0.000198

.000151

: .000171 : .000149

0.000116 : 0.000074

.000107 : .000063

.000093 .000060

LT

L 45°

LE

:

Panel B-2 (Average thickness = 0.504 inch)

.000326

.000421

: .000103 : .000089 : .000072 : .000039

. .000122 .000089 : .000072 : .000042

.000100 : .000077 : .000057 : .000040

:

Panel C-2Avera ae thickness = 0.748 inch)

LT .000202 : .000080

L 45° : • • • • • • • a • • • •

♦ • • .000063

: .000066 : .000055 : .000031

: .000043 : .000043 : .000023

LR .000270 .000051 : .000044 : .000030 : .000025

Kept. No. 1845-A

Table 6.--Details of loading and shear strains in core of rectangular sandwich strips at an applied load of 100 pounds.

2

24z

2

V

4

LOADING DIAGRAM 2

P

2 I

THEORETICAL SHEAR DIAGRAM

Specimen:Orientation:Deflection: Shear strain in core at location

:Modulus of

No. : of coral : at center:

(1) : (2)

: of span :

:

:

1

(3) : (4)

Inch

:

2

.

:

3

: (5) : (6)

:

:

4

(7) :

•

: rigidity

: of core

: material

(8)

: Iplin. : In./in. : In./in. : In./in. , : P.s.i.

AB 2

AB 3

BB 2

BB 3

Av.

CB 2

CB 3

D13 2

DB 3

Ay.

A2 B2

A2 B3

Av.

Al B2 :

Al B3 :

Av.

:

:

:

B2 B2 :

B2 B3 :

Y.

Bl B2 :

Bl B3 :

Av.

R

R

R

R

T

:

:

: 0.054

.053

: 0.00212 : 0.00268 : 0.00000 : 0.00254 :

: .00223 : .00355 : .00000: .00256:

34,120

:

.052

.o54 : .00193: .00218 : .00042 : .00223 : 27,700

.053

: .00218 : .00235 : .00037 : .00203:

27,760

31,500

.00212 : .00269 : .00020: .00234: 30,270

.o49

.o49

.o48

.049

.049

.00108

.00127:

.00091 :

•. .00135 :

: .00115:

.00153: .00000 :

.00106: .00019 :

.00062 : .00033 :

.00117 : .00040 :

.00110 : .00023:

.00120: 68,100

.00122: 65,200

.00113 : 82,600

.00121 : 62,800

.00119 : 69,675

Specimens with 0.012 inch thick aluminum faces

Specimens with 0.064 inch thick aluminum faces

:

.125

: .121

.123

.00310 : .00262

.00266 .00227

.00024: .00235 :

.00000 : .00227 :

.00288 : .00244 .00012 : .00231 :

.117 • .00147 : .00311 : .00000 : .00139 :

.118

.118

.00181 : .00208: .00106 :

.00177 :

• .00l64 : .0026o : .00053 : .00l58 :

.024

.024

.024

.020

.021

.020

:

:

..

.00155 :

.00151 :

.00153 :

.00066 :

.00077 :

.00072 :

.0

0 17 8

.00155

.00166

: .00000 : .00178 :

: .00031:

.00163 :

: .00016 : .00170 :

.00078

.00070

.00074

:

:

: .00000 : .00066

.00000 : .00085 :

.00000 : .00076 :

-In all cases the R or T symbols (Figure 1) indicate the orientation with respect to the long dimension of the bending specimen.

Rept. No. 1845-A

C)

H cd

H cd il 1

1>i

1

N

"

I

r r

-ct.

-

Pi c f) P.1

r- •r-1

U) a)

U)

0 r, rci ,

•,--1",

-P r--1

0 P-b,

4) Pi!

P-1 d 1

(Ai

CD

CHI

0,1

0

1

Jrd

•,--ii

+? p i

4 r-1 0 ci--I I 0 rri 0 cv3 rt,

• . r-1 d f, t

0 rc-1 co ,

47-4 W.

4-) al 0

O 0

•„1 H r d ci--4

.,

0

0

O Pi

O 9-1 lix r.-i

+ 3 1-P

O rf) r0

4

0 i 0

0 •ri

•ri '

CH

0 c i.

O

4 c f-4 -I.

.4) CO

' 0 'H

0 • PI td

(I) 0 (1.)

I

I

I ta r

.,-4 d p4

C14

-1-) cd 0 cd ta t a)

, -4

1

I

1 g '' A

0 0 ra

......, 1

1 s• •• I* •• •• fit 411 40 •• •• c

LC\ Ckl C\1

•• •• •• •• ••

H

••

43

./......

0) c f-i

0

H p a) cH cd

0+

•

N rn

H cr- p

0 cd -P cf) ro P4 0 0

Fi 0

_ i

C

........... --..

.

O •H 0\ f1 tr1

N-CO

'DK1 ‘.0 al H H 0

0 -1-

H 0

•

•• do* •4 •• ••

1 ord

I 1O CO

I 0

O I

O I

.

1-4 0 4-

•H

TS 0 a) a) E1

3

P4

•• ••• c---

S—'1.1

• e• • ••

0\ H CO

0 0000

• • •

1

•

0

1

.

••

0

0

•

+) 1 • .

010 II lie •• *0 •• ••

(i) 1

CH I 0

I ' 0 0 ra p 1

I

0 4-) ei-t 0

I <4 0

P-4

O a)

0

0 H q

0i

CHi i kr)

#

I

I

4

II-

•• •ok •• •• •• •• •• •• •• •• •• rci

4-

0

) cd cd .H n

4 rti 01 +)

CO M

M

MO •• •• •• 11. •• •• •• •• le rci

•• 4140 •• ••

CO C---, \.0 0\

1 ?) e)

8

0

• • • •

•6 •• •• ill

•

\t,a

H T-1

\r)

H H 0

0000 0 0

0000 0 0

• •

0

••••

•• •• •• ••

••

••

••

0

•

••

•• a) a) g "P

(1) 0 Pi

-1-) •H

I I01

......1- rizi

..1--1 (1) 0 ct) a) s--I

I I1-9

P

•• •• •• •• •• •• •• •• •• ••

0000 0 0

LC1 LC\ if\ LC\ L.C1 If •

4000

4-P(C'J H

•

4- 4-

00 ea •• •• •• •1 tr1

0 04

E-1 Cn t)

I

1H

•• •• •• •• •• II* •• •• f• •• ••

03 o)

.H

• pw

Cti 0

CT-4

ICU 0 tr-\

II

LC\ I.C\ LC\1 4-1 tr\

H

0\

•• •• •• •• •• ••

•• •• •• d• •• •• •• •• •• •• 111•

0 ibM 0

P4

Ca r-4

4) to a)

0000 o o

0

• • • 0

C A \ 7)

• •

.4

<4

LC\

.. •• ••

(4 Pc) P21 fil r-41

4-i

0

4-i

0

4-4

0

03

(1) ttO a)

8

H

0 al

4•

HHHH t

.4

'•

Hi a)

14

--re -

4.

4*

AW

-10,-

41".! 40:0000

30,Astr.

11.-w1104,

0

444111P:00:4.0

00

04"4.

4.0

4 M,

Figure l.--Section of a block of aluminum honeycomb core material made from perforated aluminum foil. Directional orientation referred to in the text is L (longitudinal), R (radial), and T

(tangential). In this study, shear stresses were measured in the LR, LT, and in the longitudinal direction at 1 5 degrees to the RT planes, referred to as L 45° in the report.

Z M 82307 F

k— 2"—.j

V

7"

SHEAR

L R DIRECTION

6"

—IT

1,

1 —

-

lc\11 1

7—

>i

IT

Ct I:"

,I

N

N

K

-.1

\ 1 cc)

\ .-- 2"---,,i

\

(;)

4"

0

6"

SHEAR

L R DIRECT/ON

6

ii

k

SHEAR

L R DIRECTION

6

2 4 "

Z X 106 598

Figure 2.--Details of panel construction showing core orientation, location of insert, location of points at which shear strains were determined, and the distribution of shear specimens cut fr©a each panel.

,,,,,....•••••••• • i901141‘444A1P4411

Figure 3.--Circular sandwich panel under test for determination of shear stresses in core. Load is applied to the top of the central insert by applying a tensile load on a flexible cable which terminates in a spherically seated cable clamp which is visible in the photograph. The strain gages, which have a 1-inch gage length, are set to read the differential movement between the top facing

(fixed knife edge on clip) and the bottom facing (movable knife edge resting on protruding bolt attached to bottom facing).

Strains were read by means of the autocollimators shown. Readings were taken simultaneously at two points, and the test repeated until readings at all points were obtained.

M

Io5 682

...„„ „.„

Figure 4.--Cut-away view' showing Tuckerman strain gage in position for measuring differential movement of top and bottom facings. Double nuts secure the 1/16-inch diameter bolt to the bottom facing. The aluminum clip supporting the strain gage is glued to the top facing of the panel.

M1

©5683

Figure 5.-,Apparatus for conducting shear tests of specimens cut from the test panels.

Z M 83718 F

/.

'

\ U.

A

0

0.

n

0.

0.

.1

I i

'`• ke

1 i

1

0.

A

A

0

•

0.

n

0.4

•

I

0.3

A

•

LEGEND.'

- COMPUTED

---- COMPUTED

-- COMPUTED

VALUES /N LT DIRECT/ON

VALUES IN LR DIRECTION

L/M/T VALUES, K

.:

-

.

-1 4--, c(= ..,

0 TEST

• TEST

A

TEST

A TEST

D

TEST n TEST

VALUES

VALUES

VALUES

VALUES

VALUES

VALUES

PANEL I A (LT DIRECTION)

PANEL I A (LR DIRECT/ON)

PANEL 2A (LT DIRECTION)

PANEL 2A (LR DIRECTION)

PANEL 3A (LT DIRECTION)

PANEL 3A (LR DIRECT/ON)

7

PI m r TTI17-t-cii

0

0.2

n n

0./ n

0

2 3 4 5 6 7

RADIUS OF PANEL (r) (INCHES)

8

2 x 106 599

Figure 6.--Computed and observed radial variation in shear stress in the cores of panels of 1/4-inch nominal thickness.

9

/0

/.0

0.9

II

0

4L

0.8

1

'

0.7

0.6

I

1

1

1

A U a k

0.5

0.4

n

•

• Q n

•

0.3

0.2

0./

0

LEGEND.'

COMPUTED

-- COMPUTED

- - - COMPUTED

VALUES IN LT DIRECTION

VALUES IN LR DIRECTION

LIMIT VALUES, K ( = -11,- , a-- 09

0 TEST

• TEST

A TEST

A

TEST

0

TEST n TEST

VALUES

VALUES

VALUES

VALUES

VALUES

VALUES

PANEL I 8 (LT DIRECTION)

PANEL / B (LR DIRECTION)

PANEL 2B (LT DIRECTION)

PANEL 28 (LR DIRECTION)

PANEL 38 (LT DIRECTION)

PANEL 3 13 (LR DIRECTION)

7r

=

PI m

T7- ( h -1- c) I

K

•

A

0

0 n

•

, .

1 '

1

2 3 4 5 6 7

RADIUS OF PANEL

(r)

(INCHES)

8

Figure 7.--Camputed and observed radial variation in shear stress in the cores of panels of 1/2-inch nominal thickness.

Z x 106 600

/0

/.0

0.9

•

•

0.8

t

0.7

0.6

A

0

0

4 • k 0.5

0.4

a

A °

0.3

0.2

0./

A

A or

1111 •

LEGEND.'

COMPUTED

---- COMPUTED

--- COMPUTED

VALUES IN LT DIRECT/ON

VALUES IN LA' DIRECTION

LIMIT VALUES, K .

-1., a' =

0

TEST

•

A

TEST

A

TEST

0 TEST

•

TEST

TEST

VALUES

VALUES

VALUES

VALUES

VALUES

VALUES

PANEL IC (LT D/ReCTION)

PANEL IC (L R DIRECT/ON)

PANEL 2C (LT DIRECTION)

PANEL 2C (LA' DIRECT/ON)

PANEL 3C (LT DIRECTION)

PANEL 3C (L R DIRECT/ON)

T =

P I m

7 (h-bc)I

K

•

____

PN

•

Z x lo6 6cu.

2 3 4 5 6 7

RAD/US OF PANEL

(r)

(INCHES)

8 9

Figure 8.--Computed and observed radial variation in shear stress in the cores of panels of 3/4-inch nominal thickness.

/0

0.0007

0.0006

LEGEND.'

PANEL

A-3

8-2

ORIENTATION OF STRAIN GAGE WITH

RESPECT TO RIBBON DIRECTION OF CORE

45° R T

0 0 •

.A

A • n n

C— 2

NOTE — LARGE SYMBOLS INDICATE COMPUTED VALUES

0.0005 et

111

(1.

(r)

0.0004

0.0003

(z)

K

C.3

Lk]

0.0002

•

0

0.000/

0

1.0

AIL

•

1.5 2.0

RADIUS OF PANELS (r) (INCHES)

2.5

3.0

Figure 9.--Relation between computed radial facing strains at the edge of the insert and observed facing strains near the insert.

Z X

106 602

Figure 10.--Method of testing small sandwich beam in bending for determination of shear stresses at various points along the length of the beam.

M 105 736

0.003

LEGEND.'

0

SHEAF?

A SHEAR

STRAINS MEASURED

STRAINS MEASURED

-- ---COMPUTED SHEAR

--COMPUTED SHEAR

IN LR .PLANE

IN LT PLANE

STRAIN L R PLANE

STRAIN L

T PLANE

0

0

0.00

A

0

A

0.00

A

0.0/2 0.032

FACING THICKNESS (INCH) z x 106 60

Figure 11.--Relation between the indicated shear strains in the core, and facing thickness of sandwich beams subjected to bending loads. (A11 specimens were subjected to the same shear stress.)

N

0.003

LEGEND.'

0 SPECIMEN

0 AVERAGE

FACING

WITH 0.012 INCH

OF SPECIMENS WITH

THICKNESS

FACING THICKNESS

0.032 /NCH

AVERAGE

FACING

OF SPECIMENS WITH

THICKNESS

0.064 INCH

-- COMPUTED SHEAR STRAIN

0.002

(/)

Lu

(f)

K

0.001

0--- - -

---0-

- - - -

-0

A

0

0 0.02 0.04 0.06

DEFLECTION OF BEAM AT POINT OF SHEAR MEASUREMENT (INCH) z x io6 6o1#

Figure 12.--Relation between indicated shear strains in the core, and deflection of sandwich beams subjected to bending loads.

(Deflection measured at the neutral axis at the point of shear measurement.)