Ferroelectrics: Towards Smaller Dimensions and Complex Structures

advertisement

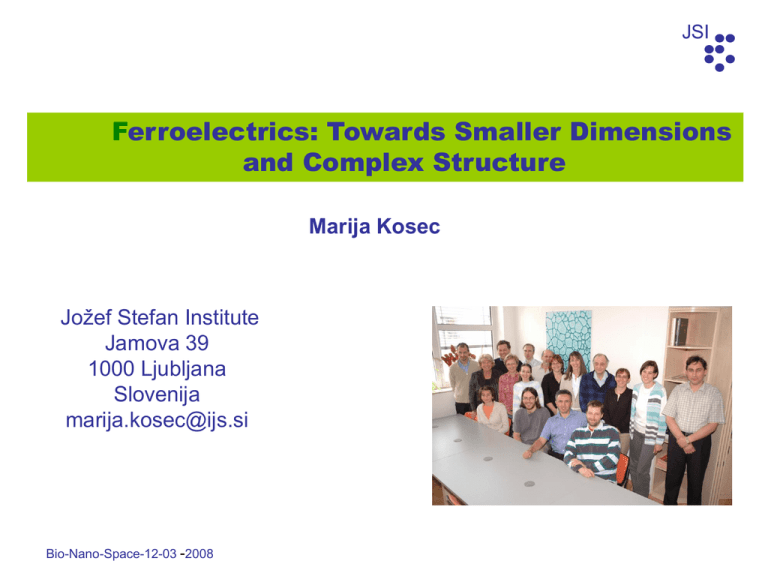

JSI Ferroelectrics: Towards Smaller Dimensions and Complex Structure Marija Kosec Jožef Stefan Institute Jamova 39 1000 Ljubljana Slovenija marija.kosec@ijs.si Bio-Nano-Space-12-03 -2008 JSI Electronic Ceramics Department, K-5 Head: Prof. Dr. Marija Kosec Staff: 20: 5 PhD, 4 Post-doc, 8 PhD students, 2 ing, 1 technician + part–time: Research Activities Materials: Piezoelectrics:Pb(Zr,Ti)O3 (PZT), Relaksors: Pb (Mg1/3Nb2/3)O3 - PbTiO3 (PMN-PT), Lead free piezoelectrics:(K,Na)NbO3 (KNN), Tunable ferroelectrics: (Ba, Sr)TiO3 K(Nb,Ta)O3, Dielectrics: CuCa3Ti4O12 (CCTO) Oxide conductors: (La,Sr)CoO3 (LSCO), La-ruthenates, Multiferoic: BiFeO3 ( BaO, PbO), LaMnO3, ZnO Bio-Nano-Space-12-03 -2008 JSI Processing: How to get extrem: properties, design, size…. Nano-powders: sol-gel synthesis (PZT) mechanically activated synthesis (PMN-PT, KNbO3, NaNbO3,KNN) Thin films by Chemical Solution Deposition (CSD) (PZT, PMN-PT, KNN, KNT, BST,CCTO) Thick film: Screen printing (PZT, PMN-PT, KNN) Electrophoresis (PZT) Ink-jet printing (ZnO) Bulk (KNN), Single crystal: KNN Devices: C-MEMS Medical transducers Pressure sensors Bio-Nano-Space-12-03 -2008 JSI Ferroelectric ceramic materials Pr Ec E (V/m) Ferroelectric and dielectric 2 -3 S (10 ) P (C/cm ) Piezoelectric E (kV/cm) 0 0.30 A: Pb B: Ti,Zr 0.28 Tunable o 900 C C (pF) 0.26 0.24 0.22 Polar structur, Electric dipols 0.20 o 0.18 700 C -200 -150 -100 Bio-Nano-Space-12-03 -2008 -50 0 U (V) 50 100 150 200 JSI Feroelectric ceramics: Composition B BaTiO3 PbTiO3 (PT) Pb(Zr,Ti)O3 (PZT), (Pb,La)(Zr,Ti)O3 (PLZT) Pb(Mg1/3Nb2/3)O3 (PMN) Pb(Mg1/3Nb2/3)O3 – PbTiO3 (PMN-PT) Pb(Zn1/3Nb2/3)O3 – PbTiO3 (PZN-PT), (PMN-PZN-PT) PbSc1/2Ta 1/2 O3 high lead content (~60w%) problems ecological Since last ten years: searching for lead free materials Bio-Nano-Space-12-03 -2008 A O lead-free ferroelectric materials: JSI Sodium potassium niobate (K,Na)NbO3 s.s. (KNN). KNbO3-NaNbO3 phase diagram The best piezoelectric response for the compositions close to the MPB:KNN50/50 TD 4.2 94.4 450 KNN-Sr 4.2 96.0 KNN PbNb2O6 5.6 tan d33(pC/N) kp kt 0.06 70 0.25 0.4 500 0.04 90 0.27 0.5 220 0.02 100 0.34 B.Malič, J.Bernard, J.Holc, D.Jenko, M.Kosec, J.Eur.Cer.Soc.,(2005) 2707 Bio-Nano-Space-12-03 -2008 Bulk: mm, cm range JSI Ferroelectrics: Towards Smaller Dimensions and Complex Structure Courtesy of Ferroperm Piezoceramics S/A Thick films >1m Thin films < 1m 100 nm 100 nm Cross-section SEM of 32Mbit NFRAM, from: H.S.Joo, Integr. Ferroel., 48(2002), 119. Bio-Nano-Space-12-03 -2008 JSI Thick film processing powder synthesis: Tem. PbO+ZrO2+TiO2 Pb(Zr,Ti)O3) Chem.reactions crytical Shaping clamping Firing Thick film Bio-Nano-Space-12-03 -2008 Thick films >1m JSI Thick film procesing Powder synth. shaping screen printing ink jet printing electrophoretic deposition firing S queegee M a sk thick film P a s te S c re e n S u b s tra te Bio-Nano-Space-12-03 -2008 JSI modeling 3,0E-05 Maximum deflection [m] 1 2,5E-05 1 Cantilever 2 2,0E-05 3 1,0E-05 Diaphragm Linear (Bridge) Linear (Cantilever) Linear (Diaphragm) 1,5E-05 5,0E-06 Bridge O p to -e el c tron ci F bi re op tci cab el con tro lel r V O p tci a lsen so r hea d 2 0,0E+00 0,0E+00 3 B A 5,0E+03 1,0E+04 1,5E+04 Pressure [Pa] Bio-Nano-Space-12-03 -2008 Marina Santo JSI LTCC/Au/PZT/ Au LTCC/PZT barriere/ Au/PZT/Au Microstructure after firing 1h 850oC. Bio-Nano-Space-12-03 -2008 JSI displacement Displacement ATP05_LTCC 6 Tip displacement [um] 5 4 200V=3µm 3 AV5L-M1++ AV5L-M1+AV5L-M1++2 AV5L-M1+-2 2 1 0 0 100 200 300 400 500 Voltage [V] dimensions 12.0 × 4.0 × 0.22 mm - 40µm thick PZT Bio-Nano-Space-12-03 -2008 Bulk: mm, cm range JSI Courtesy of Ferroperm Piezoceramics S/A Thick films >1m Thin films < 1m 100 nm 100 nm Cross-section SEM of 32Mbit NFRAM, from: H.S.Joo, Integr. Ferroel., 48(2002), 119. Bio-Nano-Space-12-03 -2008 Chemical Solution Deposition (CSD) of Pb(Zr,Ti)O3 PZT Synthesis Solutionprecursor:Pb,Zr,Ti Spinnig substrate wet film Drying, 200 C dry film Pyrolysis, 350 C substrate substrate dense, amorphous film Crystallization, 600 C Bio-Nano-Space-12-03 -2008 substrate dense, crystalline film JSI Synthesis of PZT solution precursor 2-methoxyethanol method CH3-O-C2H4-OH O CH2 n-1(RO) M O CH2 R Turova, Turevskaya, Kessler, Yanovskaya, 2002. Bio-Nano-Space-12-03 -2008 JSI Pb(OAc)2+x Zr(O R)4 +(1-x) Ti(O R)4 + CH3-O-C2H4-OH Reflux destilation PZT-solution (sol) spinning Pt/Si –substrat drying@ 200oC pyrolysis@ 350oC crystallization@ 600oC PZT thin film Budd, Dey, Payne , 1985 JSI Pb(OAc)2 / PbO + Zr(n-OBu)4 Ti(n-OBu)4 Substrate 100 nm Pt/ 10 nm TiO2/SiOx/Si CH3-O-CH2CH2-OH 4x Dissolution Reflux (2 h) Distillation Spin-coating Drying, 200 oC, 2 min Heating, 400 oC (hot-plate) Sol (CM=0,5) Single-step 1×(400 oC, 30 min) 1×(400 oC, 60 min) Multi-step Excess of PbO: 10 mole % Bio-Nano-Space-12-03 -2008 4×(400 oC, 5 min) 4x JSI Design of microstructure by the constant orientation gives a unique possibilities to study microstructure-properties relationship 4x200/2 + 400/30 60 2 P (C/cm ) 40 100 nm Pt Columnar microstructure Int. (A. u.) P <111> 25 30 * 35 -10 0 -20 4x(200/2 + 400/5) 20 4x(200/2 + 400/5) 0 -20 4x200/2 + 400/30 Si 20 -40 40 45 2 (Deg.) Orientation:constant 10 20 E (V) Equiaxed grains 100 nm 50 -60 Properties microstructure M. Mandeljc, M. Kosec, B. Malič, Z. Samardžija, Integrated Ferroelectrics, 30 (2000), 149. M. Mandeljc, M. Kosec, B. Malič, Z. Samardžija, Integrated Ferroelectries, 41 (2001), 163. Bio-Nano-Space-12-03 -2008 Ec/(kV/cm) 2 Pr/(C/cm ) 35 25 20 Bio-Nano-Space-12-03 -2008 Z zu ( lta 111 ti ) H ZT Temperatura, T/ C o Tem.(oC) PZT 35/65, (111) Kim 1995 PZT 40/60, ? Lefevre 1996 ua 30/ ng 70 19 , (1 99 11 ) P PZT 40/60, ? n T 3 aš 0 Maki 2002 i r /70 e , 30 P JSI 15 10 150 125 100 75 50 25 400 450 500 550 600 650 700 400 450 500 550 600 650 700 JSI Design of orientation by lead source Pt (111) (111) Intensity (Arb. units) ? (100) Si (200) PbO PbAc 20 25 30 35 40 45 50 2 (Deg.) XRD spectra of PZT 30/70 films: effect of lead-source, 4 x (200oC, 2 min.+ 400oC, 5 min.) Bio-Nano-Space-12-03 -2008 JSI Crystallization mechanism 400oC 1-15 min Bio-Nano-Space-12-03 -2008 Crystallization mechanism How can be formed? From Pb in Pt! Pb? From PbO in PZT How? Reduction? How? Oxidation of organic C+O2= CO2 2H2+ O2 =2 H2O Important: amorphous phase must contain enough organic. It is provide by the choice of precursors. Bio-Nano-Space-12-03 -2008 JSI JSI Reflect Array antenna 2 1 Sourc e and /or Rec eiver top surface of the plane 0.30 0.28 o 900 C C (pF) 0.26 0.24 0.22 0.20 o 0.18 700 C -200 -150 -100 -50 0 U (V) Unit cell of radiating element Waveguide with metal iris Phase shifting components RETINA: Reliable, tuneable and inexpensive antennas by collective fabrication processes, EU, 6th FP, Thematic priority: Aeronautics and Space Bio-Nano-Space-12-03 -2008 EADS (D) TAS (F) IMEC (B) EPFL (CH) COV (F) ESIEE (F) JSI (SI) HYB (SI) 50 100 150 200 JSI BST 30/70 Compositions with a higher Ba-content At RT: DIELECTRIC CONSTANT -Higher permittivity for solid solutions with a higher Ba/Sr ratio but also a higher T-dependence of . -Expected: higher tunability Temperature dependence of permittivity for BST ceramics Bio-Nano-Space-12-03 -2008 Tagantsev et al., J. Electroceramics, 2003 Ba0.3Sr0.7TiO3 (BST) Ba-acetate + Sr-acetate 0.30 Ba (CH3COO)2 +0.70 Sr(CH3COO)2 Dissolved in acetic acid (100 %), R.T. CH3COOH + Ti n-propoxide Ti(OC3H7)4 Dissolved in 2-methoxyethanol, R.T., inert atmospere CH3-O-CH2CH2OH Mixing at 60oC, inert atmospere BST-precursor solution (0.25M, 0.4 M) Alumina substrate (25.4 x 25.4 mm2) polished, 99.6 %, ε ≈ 9.8) Bio-Nano-Space-12-03 -2008 Spinning Pyrolysis Crystallization JSI Materials characterization: JSI Phase composition: XRD (CuKa) Microstructure: AFM, FE-SEM Grain size: lineal intercept (~ 100 grains) Dielectric characterization: Air-gapped capacitors (0.75 x 1.5 mm2) Cr/Au electrodes by lift-off photolithography C (V): 0V+200V0V−200V0V at 1 MHz (JSI) and 8 GHz (V. Cherman, EPFL) Gap (2-10 m) Au/Cr electrode BST film Alumina substrate Bio-Nano-Space-12-03 -2008 Vendik model Substrate: 25.4 mm x 25.4 mm JSI Microstructure: effect of annealing conditions 900 °C, 15 min. 700 °C, 15 min. Grain size: 70 nm T increases 100 nm 100 nm 700 °C, 60 min. Grain size: 40–45nm 900 °C, 60 min. Grain size: 80 nm 900 °C, 60 min. 700 °C, 60 min. 100 nm 100 nm FE-SEM images of BST films on alumina annealed at 700 and 900 °C. Bio-Nano-Space-12-03 -2008 JSI 0.30 900oC 0.28 o 900 C = 722 ± 50 n = 1.93 0.26 C (pF) 100 nm 0.24 0.22 700oC 0.20 100 nm = 345 ± 35 n = 1.49 o 0.18 700 C -200 -150 -100 -50 0 50 100 150 U (V) C-V response of BST film on alumina annealed at 700 °C and 900 oC for 60 min. 1MHz, RT, gap width: 8.5 ± 1 m. Left: surface microstructures of BST films. Bio-Nano-Space-12-03 -2008 200 Thanks Dr. Barbara Malič Dr. Janez Holc Dr.Marko Hrovat Dr.Danjela Kuščer-Hrovatin Dr.Andreja Benčan Dr. Tadej Rojac Dipl. ing.Silvo Drnovšek Dipl. ing.Jena Cilenšek Ing. Srečko Maček Darko Belavič, dipl. ing Dr. Marina Santo- Zarnik Dr. Mišo Vukadinović Mitja Jerlah Dr. Goran Dražič Dr.Stojan Stavber Dr. Vid Bobnar Prof. Adrijan Levstik Bio-Nano-Space-12-03 -2008 JSI Prof. Nava Setter, EPFL,Lausanne Prof. Rainer Waser, RWTH Aachen Mrs. Wanda Wolny, Ferroperm Piezoceramics, Copenhagen ARRS, EU:LEAF, MINUET, MIND, RETINA Thank to you!