EOQ

advertisement

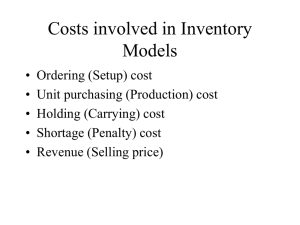

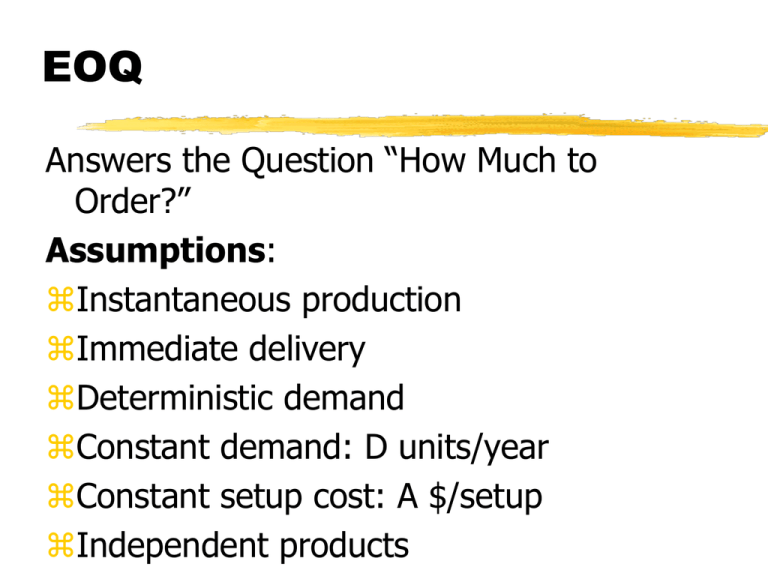

EOQ Answers the Question “How Much to Order?” Assumptions: Instantaneous production Immediate delivery Deterministic demand Constant demand: D units/year Constant setup cost: A $/setup Independent products Inventory EOQ view of Inventory Order Quantity Q Time Costs • Setup Costs – A $/setup – How many setups if we make Q each time? • Why not just make D units in one setup? Inventory Cost Usually billed as a “holding cost” Essentially interest on the money tied up in inventory h $/unit/year Example: Holding 100 units for 6 months costs: ? Inventory holding Cost h*Average Inventory A Model Lot Size or Order Quantity: Q units Average Inventory Level: Q/2units Annual Demand: D units/year Order Frequency: every D/Q times per year Average Variable Cost/Year: TVC = h*Q/2 +A*D/Q The EOQ Use Calculus to find the value of Q that minimizes TVC(Q) Or... Total Variable Cost Holding Costs Transaction Costs TVC TVC Order Quantity Total Variable Cost Holding Costs Transaction Costs TVC TVC Order Quantity Total Variable Cost Holding Costs Transaction Costs TVC TVC Order Quantity Total Variable Cost Holding Costs Transaction Costs TVC TVC Order Quantity The Economic Order Quantity h Q/2 = A D/Q Q2 = 2 A D/h Q = SQRT(2 A D/h) CAVEAT: Make sure you use commensurate units! An Example Raw Material X Quarterly demand: 6,000 units Cost per unit: ~ $25/unit Holding Cost: say 10% per year Transaction Cost: $100/order EOQ = SQRT(2 CT D/ CI) = SQRT(2 * 100 * 6,000/(0.025*25)) ~ 1,385 units per shipment Robustness 100% Robustness of the EOQ % error in A*D 80% % error in Q % error in TVC 60% 40% 20% 0% -20% -40% -60% Robustness 100% Robustness 80% % error in h % error in Q % error in TVC 60% 40% 20% 0% -20% -40% -60% EPQ Answers the Question “How Much to Produce?” Assumptions: Instantaneous production Constant production rate: P > D units/year Immediate delivery Deterministic demand Constant demand: D units/year Constant setup cost: A$/setup Independent products Inventory EPQ view of Inventory Production Quantity Q Max Inv. Level Length of Prod. Run Time A Model Lot Size or Production Quantity: Q units Average Inventory Level Production run lasts: Q/P Inventory grows at rate: (P-Q) So, max inventory is: (P-D)Q/P = (1-D/P)Q Average inventory is: (1-D/P)Q/2 Order Frequency: every D/Q times per year Average Variable Cost/Year: TVC = h*(1-D/P)Q/2 +A*D/Q The EPQ Use Calculus to find the value of Q that minimizes TVC(Q) Or use the previous answer... TVC = h*(1-D/P)Q/2 +A*D/Q = h’Q/2 +A*D/Q So, Q = SQRT(2 A D/h’) = SQRT(2AD/h(1-D/P)) An Example Raw Material X Quarterly demand: 6,000 units Cost per unit: ~ $25/unit Holding Cost: say 10% per year Transaction Cost: $100/order Quarterly Production Rate: 8,000 units EOQ = SQRT(2 CT D/ CI) = SQRT(2*100*6,000/(0.025*25*(1-6/8))) ~ 2,771 units per run A Model Divide the planning horizon into time buckets t = 1, 2, ..., T Dt = units of demand in period t ct = unit production cost in period t At = setup cost in period t ht = inventory holding cost in period t Qt = the lot size in period t It = units in inventory at the end of period t Heuristics Lot-for-lot: Make what is required each period. Fixed Order Quantity: Order the EOQ Period Order Quantity: Calculate the EOQ, Q. Convert to order frequency: T = Q/D. Orders sized to last for time T.