200 GPM - Renton Fire & Emergency Services

Hydraulics

Theory and application allowing control and use of fluid pressure

Hydraulic Theories

Understanding the theoretical and practical application of hydraulics essential for pump operation. The study of fire ground hydraulics is divided into two categories, theoretical and rule of thumb.

The driver/operator must be able to apply both.

Elements of Hydraulic Calculation

Nozzle Loss

Attack Line Loss

Elevation Loss

Manifold/ Appliance

Standpipe Loss

Supply Line Loss

Terminology in Friction Loss

Formulas

NP - Nozzle Pressure

FL Friction Loss

AL Appliance Loss

EL Elevation Pressure

TPL - Total Pressure Loss

NPDP - Net Pump Discharge Pressure

Theoretical

In the classroom and non-emergency activities of the fire department, mathematical equations are used to calculate the flow characteristics of our equipment and systems. This method of calculation is commonly referred to as

“Theoretical Hydraulics”. By using mathematical formulas, a relatively accurate calculation of the total probable friction loss is obtained. This method is normally more accurate than Rule of

Thumb.

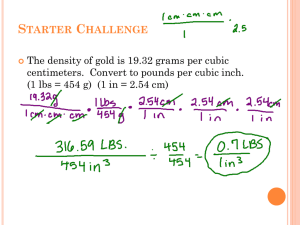

Theoretical Formula

There are many formulas and methods for figuring friction loss but the Renton Fire

Department has adopted the following for use in its training program.

FL = CQ 2 L

Where

Q = Quantity

C = Coefficient

L = Length in 100’s

Hose Coefficients

Coefficients for Renton Fire Department hose:

1 ¾ “

2 ½ “

3 ½ “

5 “

C = 15.5

C = 2

C = 0.34

C = 0.08

Siamesed Hose Lines Coefficients

Two 2 ½” 0.5

Three 2 ½” 0.22

Rule of Thumb

On the fire ground, the driver/operator normally works with a condensed and simplified application known as “Rule of

Thumb Hydraulics”. Rule of thumb hydraulic formulas are a chosen series of fixed, rounded values that can be applied to an operation sequentially to build a water delivery system.

Rule of Thumb

Fixed Rounded Value Examples

2 ½” Combination Nozzle 250 GPM

1 ¾” Combination Nozzle 125 GPM

1 ¾” Hose 25 psi FL / Section

2 ½” Hose 06 psi FL / Section

Master Stream Devices 25 psi FL

Appliances (Wye etc…)

Appliances (Wye etc…)

Elevation

0 FL @ <350 gpm

10 psi FL @ > 350 gpm

05 psi FL / Floor

Appliance Pressure Loss

< 350 gpm no calculated loss

> 350 gpm 10 psi per appliance

25 psi for all master stream devices

25 psi for all standpipes

Nozzles and Tips

Types of Nozzles

Solid Stream

Broken Stream

Periphery Deflected

(Combination )

Impinging stream

(Naval type)

Nozzle Design

The purpose of any nozzle is to provide a restriction of the flow to build pressure. This restriction, and subsequent created pressure, provides a usable velocity to project the water stream. For any one flow, there is one correct nozzle size (restriction) to develop the optimum pressure and velocity.

Restriction

Designed Nozzle Pressure

Smooth Bore Nozzle - Hand line - 50 PSI

½” thru 1 ¼” nozzles

Smooth Bore Nozzle - Master Stream - 80 PSI nozzles 1 ¼” and over

Fog Nozzle - 100 PSI all nozzles

Solid Stream -

Characteristics

The mechanical characteristics of a solid stream nozzle produce a compact stream that has a higher mass and velocity. These features typically yield better reach and penetration.

Solid Stream -

Composition

The interior diameter of the nozzle is gradually decreased until it reaches a point just short of the outlet. At this point the straight cylindrical bore has a length from 1 to 1 ½ times its bore, this area is known as the stream shaper

Solid Stream Mechanics

Water flowing through a nozzle is subject to the same physical principals of friction as hose. The net effect of friction in a solid stream nozzle is the creation of a laminar flow. The center of the flowing stream is faster than the edge. This creates a peripheral turbulence that is visible after the stream exits the nozzle.

Solid Stream - Formulas

Discharge Volume:

29.7 x D 2 x NP

Nozzle Reaction:

1.57 x D 2 x NP

Fog Stream - Characteristics

A stream of water remains in a solid mass, not losing continuity until it strikes an object, is overcome by gravity or is changed by friction with the air. Fog stream nozzles are designed around this theory and are commonly called broken stream appliances

Fog Stream - Composition

All fog streams are of two mechanical types, Periphery-deflected or impinging stream. The shape and reach of a fog stream are results of the appliance shape and the velocity/pressure of the water.

Impinging Stream

Impinging Stream fog patterns are produced by driving jets of water together at a set angle to break the streams into finely divided particles. These appliances generally produce wide angle fog patterns.

Periphery-Deflected

Periphery –Deflected streams are produced by deflecting water from the periphery of an inside circular stem to the inner circumference of the adjustable barrel. The position of the barrel varies the shape of the stream from a light fog to a straight stream.

There are two common types of these nozzles, automatic and non-automatic.

Periphery-Deflected,

Automatic

Automatic Periphery-Deflected nozzles have a spring loaded baffle assembly that reacts to incoming pressure. The baffle is calibrated to function at 100 PSI.

The model illustrated has a sliding valve which allow the firefighter to meter the flow at the nozzle.

Periphery-Deflected,

Automatic

When pressure at the nozzle is less, the baffle moves in to maintain the pattern. When the pressure is greater than

100 PSI the baffle moves out to allow more volume and minimize the nozzle reaction.

Periphery-Deflected,

Automatic

Task Force Tip nozzles have a slide valve assembly that allows the water flow at the tip to be metered. By using this valve design, the nozzle has a smoother flow and less turbulence. Note the valve position in the illustrations.

Fog Stream - Formulas

Nozzle Reaction:

0.0505 x Q x NP

Slide Valve Operation

Slide Valve

Gated ½ Way

Ball Valve Operation

Ball Valve

Gated ½ Way

Nozzle reaction is the force that a firefighter feels when he is operating a nozzle. Nozzle reaction is primarily a result of discharge pressure at the nozzle. If the nozzle pressure is lowered, the firefighter will note a corresponding decrease in the nozzle reaction.

Nozzle Reaction

To calculate the nozzle reaction use the following formulas, note same flows can often be developed at a far lower nozzle reaction in solid stream nozzles. Traditional thought is that solid bore hand lines should be pumped at 50 psi. Any nozzle pressures higher than 65 psi becomes unmanageable. In the following table review and compare the reaction force of various fire streams.

Nozzle Reaction: Solid Stream

1.57 x D 2 x NP

Nozzle Reaction: Fog Stream

0.0505 x Q x NP

Handline Nozzle Reaction Chart

125 GPM

3/4” tip @ 56 NP combination @ 100 NP

150 GPM

7/8” tip @ 44 NP combination @ 100 NP

175 GPM

200 GPM

7/8” tip @ 60 NP combination @ 100 NP

250 GPM

1” tip @ 46 NP combination @ 75 NP combination @ 100 NP

300 GPM

1” tip @ 72 NP

1-1/8” tip @ 50 NP combination @ 100 NP

325 GPM

1” tip @ 100 NP

1-1/8” @ 64 NP combination @ 100 NP

1” tip @ 120 NP

1-1/8” tip @ 75 NP

1-1/4” tip @ 50 NP combination @ 100 NP

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

49 NR

63 NR

53 NR

76 NR

72 NR

88 NR

72 NR

87 NR

101 NR

113 NR

99 NR

126 NR

157 NR

127 NR

152 NR

188 NR

149 NR

123 NR

164 NR

Theoretical Formula

FL = CQ 2 L

Where

Q = Quantity

C = Coefficient

L = Length in 100’s

Hose Coefficients

Coefficients for Renton Fire Department hose:

1 ¾ “

2 ½ “

3 ½ “

5 “

C = 15.5

C = 2

C = 0.34

C = 0.08

Siamesed Hose Lines Coefficients

Two 2 ½” 0.5

Three 2 ½” 0.22

2 ½” – 400 ‘

1 ¾” – 150’

1 ¾” – 200’

125 gpm

125 gpm

Answer

100 psi NP

48 psi FL 1 ¾”, 200’

50 psi FL 2 ½”, 400’

198 psi NPDP

(36 psi FL 1 ¾”, 150’ plus 5 psi elevation is less than 200’. Pump to the highest friction loss)

200’ of 5”

200’ 1 ¾”

200’ 2 ½”

200 gpm

250 gpm

Answer

100 psi NP

5 psi elevation

124 psi 1 ¾”, 200’

10 psi appliance loss (>350gpm)

3.24 psi 5”, 200’

242.24

psi NPDP

(2 ½” FL is 25 psi, pump to the highest loss)

2 ea. 2 ½” 50’

600 GPM

1 ½” tip

200’ of 5”

2 ½” 200’

250 GPM

Answer

100 psi NP

25 psi FL, 2 ½”

10 psi AL

11.56 psi FL 5”

146.56

psi NPDP

(NP 80 psi, 1 ½” tip 600 gpm / 25 psi FL

Masterstream / 9 psi FL 2 ½” Siamese

= 114 psi. Pump to the highest loss. Gate down the Master stream if necessary)

1 ¼”

Solid Bore

1 ¾” 150’

200 gpm

250’ 2 ½’

125 gpm

1 ¾” 200’

2 ½’” 200’

250 gpm

100 psi NP

Answer

2 ½” 25 psi FL

1 ¾” 200 gpm, 93 psi FL

1 ¾” 125 gpm, 48.4 psi FL

50 psi

2 ½” with 1 ¼” 328 gpm, 53.7 psi

193 psi NPDP, pump to the highest friction loss

150 gpm

200’ 1 ¾”

40’

Answer

100 psi NP

17.36 psi EL (.434/ft)

69.75 psi FL

187.11

psi NPDP

100” Siamesed 2 ½”

200’ 1 ¾” 150 gpm

Answer

100 psi NP @ 150 gpm

69.75 psi FL 1 ¾”, 200’

34.72 psi EL (.

434 psi X 8 floors above the 1 st )

25 psi FL Standpipe

01.125 psi FL Siamesed 2 ½”

230.59 psi NPDP

100’ of 2 ½”

200’ of 1 ¾” @ 200 gpm

Answer

100 psi NP @ 150 gpm

124 psi FL 1 ¾”, 200’

34.72 psi EL (.434 psi X 8 floors above the 1 st )

25 psi FL Standpipe

08 psi FL Siamesed 2 ½”

291.72 psi NPDP

What single adjustment could you make to cut the friction loss by NPDP by 25 psi?

2 ea. / 100’ of 2 ½”

150’ of 2 ½”

250 GPM

150’ of 2 ½”

150’ of 1 ¾”

180 GPM

Answer

100 psi NP @ 180 gpm

75.33 psi FL 1 ¾”, 150’

9.72 psi FL – 2 ½”, 150’

26.04 psi EL (.434 psi X 6 floors above the 1 st )

25 psi FL Standpipe

09.25 psi FL Siamesed 2 ½”

245 psi NPDP

The 2 ½” NPDP was 187.72 pump to the highest friction loss.

How would the excess pressure be dealt with in this line?