INTRODUCTION TO BASIC PRINCIPLES

advertisement

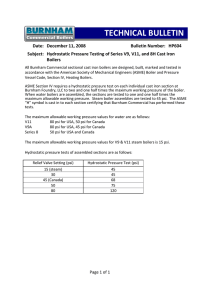

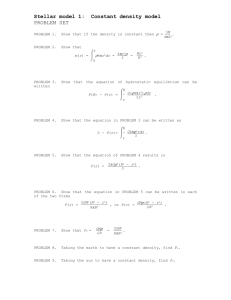

Introduction to Basic Principles Types of Level Measurement 1. 2. 3. 4. 5. A STICK/SOUNDING TAPE/SITE GLASS MECHANICAL FLOATS CAPACITANCE HYDROSTATIC PRESSURE RADAR/SONAR Typical Level Sensors Hydrostatic Pressure • PRESSURE-FORCE/AREA • Water Column • Density and Specific Gravity • P=h*SG/27.68 • Sensor Ranging Pressure vs Volume psi volume 1 4000 0.9 3500 0.8 3000 0.7 2500 0.5 psi 0.4 volume pressure 0.6 2000 1500 0.3 1000 0.2 500 0.1 0 0 0 5 10 15 height 20 25 30 0 5 10 15 height 20 25 30 Pressure is a function of height Volume is a function of shape Scale Calculations • Dimensions • Calibrations • Sounding Chart • Application nData Sheet 4-20mA Basics • Can be run long distances with minimal loss ~1,000 ft+ • Varying impedance or supply voltage will not affect the signal. • Low electromagnetic susceptibility • Only requires 2 wires to operate Typical 4-20mA Loop Remote Indicator Loop KING Filters • • • • Single stage or dual stage Main Line or Point of use Polisher Selection Scrubber Selection Coalescing Filtration • Compressed air enters • Travels through filter media • Oil and water attach to fibers • Grow into droplets and fall off into bowl • Replace elements yearly or as needed King’s Outside to Inside Flow • More surface area for particulate • Nozzle shaped outlet for better discharge Removing Oil/Water Vapor • Using desiccants to remove vapor through adsorption Desiccant Dryers • Compressed air passes through an adsorbent media (desiccant) such as activated charcoal, silica gel, or molecular sieve.