Powertrains & Brakes

advertisement

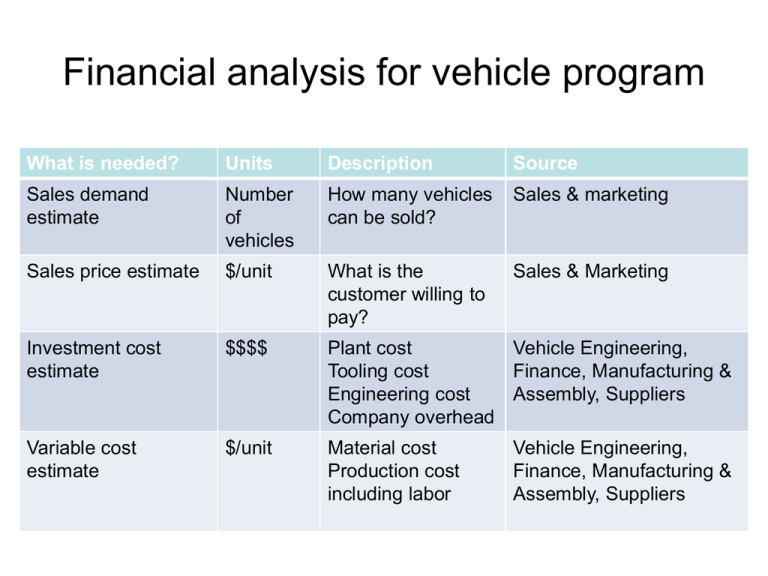

Financial analysis for vehicle program What is needed? Units Description Source Sales demand estimate Number of vehicles How many vehicles can be sold? Sales & marketing Sales price estimate $/unit What is the customer willing to pay? Sales & Marketing Investment cost estimate $$$$ Plant cost Vehicle Engineering, Tooling cost Finance, Manufacturing & Engineering cost Assembly, Suppliers Company overhead Variable cost estimate $/unit Material cost Production cost including labor Vehicle Engineering, Finance, Manufacturing & Assembly, Suppliers Profit Analysis Profit = Revenue – cost Where Revenue = selling price*number of vehicles sold Cost = investment cost + variable cost* number of vehicles produced Break even volume is the number of vehicles need to be sold so that there is no loss Break even Volume = Investment cost/(selling price – variable cost) Examples of Successful & Unsuccessful Programs Entity Estimate Actual Actual Actual Sales Volume 150,000 120,000 75,000 150, 000 Sale Price ($/unit) 22,000 22,000 22,000 18,000 Investment Cost ($) 500 M 500 M 500 M 500 M Variable Cost ($/unit) 17,000 17,000 17,000 17,000 Total Profit (M$) 250 M 100 M - 125 M -350 M Break even volume = 500,000,000/(22,000-17,000) = 100,000 vehicles Your Calculations 1. 2. 3. 4. 5. 6. Estimate selling price for your car from market survey Estimate the number of vehicles that can be sold Assume variable cost to be about X% of the selling price Assume investment cost to be Y RM Figure out break even volume and profit Figure out a way to distribute investment and variable cost to systems Investment Cost Body Chassis Powertrain Climate Control Electrical Variable Cost Body Chassis Powertrain Climate Control Electrical Weight Analysis Curb Weight : Weight of an assembled vehicle Gross Vehicle Weight (GVW) = Curb weight + passenger & cargo weight Corner weight = weight on each suspension Curb Weight Body Chassis Powertrain Climate Control Electrical Vehicle-fixed Coordinate System • ISO (International Standards Organization) coordinate system • Defines directions with respect to the vehicle Z Vertical Yaw r Rol l p CG q Pitch X L i na it ud g n o l Y L ate ral Forces Acting on a Car, Truck or Motorcycle h B Fx f Mg x M g c os Ma sin Mg LA PM b d D A F zf L A L /2 c R h hx h h Fx r R hz F zr • • • • • • Gravity Moment Equations Tire normal forces (loads) Taking moments about point A Tire shear forces (driving or braking) Aerodynamic forces and moments Taking moments about point B yields D’Alembert (acceleration) forces Trailer hitch loads M A= FzfL + M a hx+ M g h sin c Fzf = M g cos L b Fzr= M g cos L L - M g c cos h h - M a x - M g sin L L h - h + M a x + M g sin L L + L A + PM + R h hx + R h d = hz 0 2 LA - - 2 LA + 2 PM -R L PM +R L h - Rh hx L hh +R hx L dh hz L dh + L hz L h Static Loads • Sitting statically on a level surface: W fs M g c c L W c L W rs M g c b L W b L Longitudinal Dynamics • • • • Dynamic load transfer Acceleration limits Braking limits Aerodynamic forces/moments Acceleration at Low Speed • Acceleration on a level surface with no aerodynamic reactions Wf W ( c L Wr W ( h ax L gc b L ) W fs W h ax L gc h ax L gc ) W rs W h ax L gc Climbing a Grade • No aerodynamic or acceleration effects Wf W ( c cos L h sin ) Wr W ( b cos L h sin ) L L • For small angles: cos = 1, sin = W f W fs W h W r W rs W L • = Grade angle (in radians) h L Aerodynamic Resistance Load Aerodynamic drag load DA = 0.5 ρ V2 CD A Where: CD = Aerodynamic drag Coefficient ρ A = Air density = Frontal Area of the vehicle Tire Rolling Resistance Load Rolling resistance load Rx = Rxf + Rxr = fr Wf + fr Wr Where: fr = Rolling Resistance Coefficient Wr = Rear axle load Wf = Front axle load fr = 0.015 or 0.01*(1+ V/160) Where, V is vehicle speed in km/h Powertrain Applications • Powertrain development – Architecture evaluation (FWD, RWD, 4WD) – Acceleration (0-100 kph, passing), top speed – Tuning (engine, torque converter, transmission matching) – Traction limits – Fuel economy Powertrain Architecture • Traction-limited acceleration depends on loads on the drive wheels • I.e., F F x z Front wheel drive Rear wheel drive Four wheel drive Powertrain Architecture • Components in a solid axle rear drive Engine Dyno Performance • Steady speed; Wide Open Throttle (WOT) Basic Acceleration Model Fx M a x a x Fx ax gc gc W = W gc ax and P F x V P gc V W 1 P V W • Simple acceleration model used by highway engineers • Acceleration is: – Proportional to power to weight ratio – Inversely proportional to speed Example of Simple Model • Simple acceleration model used by highway engineers – It over-predicts performance with actual P/W ratios – Models are calibrated with effective P/W ratio 1 Simulated Vehicle (250 kw, 1833 kg, with all losses) 0.9 100% Efficient 0.8 Acceleraiton (g) 0.7 50% Efficient 0.6 0.5 0.4 0.3 0.2 0.1 0 0 20 40 60 80 100 Speed (km/h) 120 140 160 180 200 Tractive Force Performance • Tractive force vs. speed: – Reflects engine torque curve – Depends on gear • Low (1st) gear – High tractive effort – Limited speed range • Higher gears expand the speed range but reduce tractive effort • Multiple gears approximate constant engine power • Continuously variable transmission (CVT) can follow constant engine power curve Acceleration Performance (M+Mr) ax = T Ngf ηgf/r – Rx – DA – Rhx – W sinθ Where M = vehicle mass = W/g Mr = equivalent mass of rotating components ax = longitudinal acceleration T = Engine Toerque Ngf = combined ratio of transmission & final drive ηgf = combined efficiency of transmission & final drive Rx = Rolling resistance forces DA = Aerodynamic forces Rhx = Hitch forces θ = Inclination angle Mr = [(Ie+It)Ngf2 + IdNf2 + Iw]/r2 or Mr/M = 0.04Ngf+0.0025Ngf2 and Ie,It and Iw are engine, transmission, axle inertias Top Speed Calculation T Ngf ηgf/r >= Rx + DA + Rhx + W sinθ If LHS > RHS, acceleration to higher speed is possible LHS = RHS corresponds to top speed in that gear Powertrain System Design Uncontrolled Variables Aerodynamic Drag Rolling Resistance Climbing Grade Mass, Driveline Inertias Gear Inefficiencies Vehicle Design Specifications •Engine torque/power •Transmission Gear Ratios •Final Drive Gear Ratio •Torque Converter •Tire Size •Tire Traction Limit •Axle Roll Acceleration Top Speed What is needed? • Procedure for calculating top speed and time to reach 100 km/h from 0 • Procedure to calculate top speed • spreadsheet Torque Converter • Fluid coupling between engine and transmission • Stator: – Deflects return flow in direction of the impeller – Adds to torque of impeller – Turbine torque > engine torque • Zero output/input speed ratio is “stall” • Turbine input to transmission is typically two times engine torque Differential Differential Rules R ul es for F ree D iffer entials Tleft Tright Pinion Gear Ring Gear left right Carrier 2 Tcarrier 2 carrier Axle Shaft Axle Shaft Side Gear R ul es for Lo cking D iff eren ti al Carrier Gear Tleft Tright Tcarrier left right carrier Torques on a Chassis Traction Limits W W F x m ax 1 h Fx m ax b 1 L 2 r K f L N ft h F x m ax W F x m ax 1 L h L 1 L 2 r Kr N ft K W b L c c L h L K Differential Performance Brake Systems Applications • Proportioning evaluation – Weight variations (curb weight to GVWR) – High and low friction • Testing for regulatory compliance (FMVSS 105, 121..) • Stability in braking (e.g., split mu, FMVSS 135) • Evaluating effect of partial system failures Typical Braking System Rear Brake Vacuum Assist Re a r Brake Pedal b ra ke Master Cylinder lin e s Parking Brake Combination Valve t ne o n e li r F ak br s Front Brake Tire Slip Tire V Slip (S) = Vertical Load Friction Force Relative Slip V- r V 0.8 B ra kin g Co e fficie nt Contact Length p 30 m 0.6 ph Dry Adhesion 0.4 30 m s ph We t 0.2 Hysteresis 0 0 20 40 60 Wheel Slip (%) 80 100 Wheel Lockup • Front wheel lockup will cause loss of ability to steer the vehicle • With rear wheel lockup, any yaw disturbance will initiate rotation of the vehicle making it unstable • Brake proportioning strategy should allow the front brakes to lock first if ABS is not provided Anti-lock Brakes 0.8 1 le S pe ed 2 3 0 1 2 3 4 Time (sec) 5 6 7 Cycling 0.6 3 1 c a ti o n RF h ic 2 0.4 A p p li Ve LF B rakin g C oe fficie nt W he el S p ee d LR RR 0.2 0 0 20 40 60 Wheel Slip (%) 80 100 FMVSS Regulatory Requirements 1. 2. 3. 4. A fully loaded passenger car with new brakes will stop from speeds 30/60 mph in distance with average deceleration of 17/18 ft/s^2 A fully loaded passenger car with burnished brakes will stop from speeds 30/60/80 mph in distance with average deceleration of 17/19/18 ft/s^2 A lightly loaded passenger car with burnished brakes will stop from speeds 60 mph in distance with average deceleration of 20 ft/s^2 A fully and lightly loaded passenger car with brake failure will stop from speeds 60 mph in distance with average deceleration of 8.5 ft/s^2 Brake Proportioning Maximum brake force an axle can carry without locking μp(Wfs + Fxr*h/L) Front Axle Fxmf = ------------------------1 – μp*h/L μp(Wrs - Fxf*h/L) Rear Axle Fxmr = ------------------------1 + μp*h/L Where Fxf and Fxr are front and rear brake forces Wfs and Wrs are front and rear static weights μp is the peak brake coefficient h is the c.g. height L is the wheelbase Brake Proportioning Brake Force Fx = Tb/r = G Pa/r Where Fx is front or rear brake force (N) Tb is front or rear brake torque (Nm) r is the tire rolling radius (m) G is front or rear brake gain (N.m/MPa) Pa is brake application pressure What is needed • Explanation on how to draw braking limits on the chart • How to draw FMVSS requirement • How to draw applied brake force diagram • Brake pressure/brake torque relation • Brake proportion strategy graph Performance Triangles Slope p W fs 1 p Front Brake Force 2000 p h L h 1 p h L Slope p h L h 1 p L 1500 Proportioning Range 1000 500 p W rs 1 p 0 0 500 1000 h L 1500 Rear Brake Force 2000 L Brake Proportioning 1st Effectiveness F ro n t B ra ke Fo rce (lb) 2000 2nd Effectiveness 3rd Effectiveness 1500 = 0.3, lightly loaded = 0.3, GVW R 1000 Proportioning Line 500 500 1000 1500 Rear Brake Force (lb) 2000 Braking Efficiency Eb = Dx/μp Where Eb is the braking efficiency Dx is the actual deceleration μp is the braking coefficient Braking Efficiency Calculation 1. Assume front and rear brake proportioning strategy such as Pf = Pa and Pr = 0.8 Pa 2. Calculate front and rear axle brake forces Fxf = 2Gf*Pf/r and Fxr = 2Gr*Pr/r 3. Calculate deceleration Dx Dx = (Fxf+Fxr)/W 4. Calculate front and rear axle loads 5. Wf = Wfs + (h/L)(W/g)Dx Wr = Wrs – (h/L)(W/g)Dx 5. Calculate braking coefficients μf and μr μf = Fxf/Wf and μr = Fxr/Wr 6. Calculate braking efficiency Eb Eb = Dx/ (higher of μf or μr) 7. Increase Pa till desired level of Dx is reached Brake System Design Uncontrolled Variables Aerodynamic Drag Rolling Resistance Mass, C.G., wheelbase Vehicle •Brake Pressure •Brake Torque Gains •Brake Proportioning •Tire Size •Tire Friction Limit Design Specifications Deceleration Efficiency Locking Strategy Energy/Power Absorption Energy and power absorbed by the brake system during braking E = MV2/2 P = MV2/(2ts) Where M is the mass of the vehicle V is the initial speed ts is the time to stop