Eddy Current Retarder

advertisement

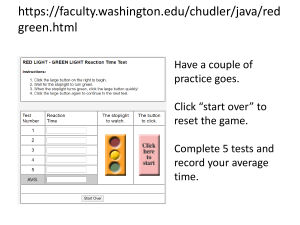

EDDY CURRENT RETARDER Indian Institute of Technology Hyderabad DIPIN K NAIR KENNETH JOSEPH PAUL NAVANEETH T CHANDRAN VIVEK D S VIVEK A K ME12B1014 ME12B1020 ME12B1025 ME12B1044 ME11B1037 INTRODUCTION This projects intends to the design and implementation of new system of retardation (braking) for automobiles The design of the new brakes is based upon the phenomenon of electromagnetic induction and eddy currents The design basically consists of very strong magnet and rotating metallic wheel The wheel develops eddy currents due to the change in magnetic flux associated to the wheel due to its rotation The eddy current development obeys Maxwell’s law of electromagnetic induction and Lenz’s law of direction of induced current The current in turn dissipates the rotational energy of the wheel as heat bringing the wheel to a stop 4/13/2015 EXISTING BRAKING METHODS Drum brakes Disk brakes Hydraulic brakes Electric brake ABS (Anti skid Braking System) Disk brake 4/13/2015 Disk brake Air brake NEED FOR ALTERNATIVE All conventional systems of braking in road vehicles uses development of contact friction for retardation These systems are probe to the wear and tear on usage Conventional braking systems produces continuous power dissipation as heat and may fail if the temperature rises too high Friction based braking methods are also not efficient under wet conditions Weight brakes add additional weight to the automobile serving no other purpose and significantly reducing traction under certain circumstances Brakes usually creates small noise on application and may also create loud screeches on hard usage 4/13/2015 DESIGN The design consists of following parts 1. Aluminium wheel 2. Mild steel shaft 3. Free wheels 4. Strong permanent magnet 5. 12v DC motor 6. 12v /2.5 Ah lead battery 7. Metallic frame 8. Braking arm 4/13/2015 PROS High impact Less friction Low maintenance requirement Less noise Simple in design High degree of safety 4/13/2015 CONS Failure to act as a holding device Usage of electric power for braking Less effective under very low velocities 4/13/2015 APPLICATIONS Already in use under some railway system Can be used for any road vehicles Equally applicable to heavy and light vehicles Can be used as additional retarder for aircrafts May also find application in virtually any rotating system which have metallic parts 4/13/2015