GPS Pasture Guidance - Oklahoma Cooperative Extension Service

advertisement

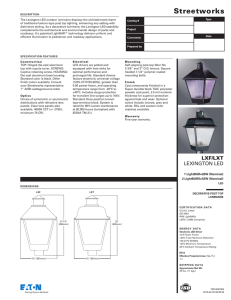

GPS Options for Pasture Operations Wesley M. Porter (Wesley.Porter@OKState.edu) Where do I start? • There are many GPS devices currently on the market. • Prices range from ~$100-thousands of dollars • Many of these devices such as a cell phone are dual purpose. • Most of these devices cannot be used as guidance aids. Devices: Car Navigation Systems • Car navigation systems are cheap and very easy to use but have poor accuracy (±50 ft.). • They have preloaded maps of defined roads and use a distance weighted algorithm to give you correct directions. • They cannot be used in any off-road condition. • This is not a device to be used in an agricultural operation. Devices: Cellular Phones • Most if not all of current cell phones have GPS capabilities. • Some of the phones, including smart phones, have the applications to log points and paths. • This data can be useful for marking and navigating to points. • However these phones cannot act as guidance aids and have too poor accuracy (±50 ft.) even if they had guidance capabilities. Devices: Handheld GPS • Most handheld GPS’s can be purchased from any sporting goods store for a cheap price. • These systems can collect, export, and download points, paths, and boundaries. • These features can be imported to specialized GIS software for viewing. • Even though the units can have features downloaded to them they are not much use in many agricultural operations. Devices: Handheld GPS • Very good for recreational uses. • Do not have the software or processor capabilities to operate as a guidance aid, not to mention the small screen would be very difficult to see. Devices: Field Computers • Field computers can be linked with an existing GPS system such as a Trimble, AgLeader, or John Deere system. • These computers usually run an agriculture based software such as Apex or Farmworks. • The software can be used for logging data and implement control but not for guidance. • The software can be used in conjunction with a guidance system for accurate applications. Devices: Lightbars Devices: Lightbars • Lightbars are an “entry” level guidance system. • They consist of a DGPS unit, a display, and a microprocessor/computer. • Lightbars range from just a row of lights to some with an LCD display screen. • A guidance path should be set with the device and an implement width entered. • It is important to note that lightbars are not “autosteering” devices, but just a guidance aid. The operator still has to manually steer the machine. Devices: Lightbars • The lightbars work by giving LED lights representing the desired guidance path. Devices: Lightbars • The displays usually give a “off-line” distance accompanied by the lighted LED’s. • Many of the Lightbars with LCD screens will show the actual guidance paths along with the current path of travel highlighted. Devices: Auto-Steering Systems • A step above lightbars is the full auto-steer systems. • These systems are offered by many companies from the factory or can be added later to certain tractors. • This system requires the set up of a guidance path, but unlike using a lightbar, once the vehicle is aligned on the desired path a button is pushed to engage auto-steer. • Once auto-steer is engaged the vehicle automatically follows the guidance path without interference from the operator until the end of the field is reached. Accuracy and Correction • Most of the above mentioned devices are not very accurate. • The typical accuracy range of the car navigation systems and cell phones falls within the range of ±50 feet. • Hand held GPS devices which are WAAS correction compatible can have horizontal accuracy down to about ±10 feet. Accuracy and Correction • There are many ways to improve the accuracy of GPS units that are correction compatible. • Most correction types are Differential correction (DGPS) including: – WAAS Correction, used by the aviation industry and has a repeatable accuracy of about ±10 feet. – Radio Beacon Correction, used and serviced by the U.S. Coastguard and Army Corps of Engineer and has a repeatable accuracy of foot to sub-foot pending on signal strength. Correction Types Continued – The private sector such as John Deere has DGPS correction that can be purchased for a yearly subscription fee. The accuracy of the private correction types is very comparable to the Beacon correction network. – RTK or Real-Time Kinematic correction is currently the most accurate correction available with repeatability ranging in the inch to sub-inch range. There are two ways to obtain RTK correction, either through a base station, or cell phone networks. Back to the Beginning: Where do I Start? • You need a device with guidance and DGPS capabilities. • An entry level guidance system is a good start and about all that is needed for pasture operations. • You will have a decent accuracy and repeatibility level which will be better than most operations without guidance systems. Benefits of using a Lightbar • A primary advantage of using a lightbar is a reduction in application errors such as overlaps and skips. • Studies have shown that operators using foam markers with chemical application will overlap about 5% of the machine width on each pass. • Lightbars can help reduce overlap to less than 3% without increasing skipped areas translating to a reduction in chemical use as much as 2%. Benefits of using a Lightbar • Improved machine operation in poor visibility. • Glare during sunrise and sunset can make it difficult to see markers and references while the lightbar can be easily seen in the cab of the tractor. • Cover crops can make subsequent passes difficult to see while the lightbar will improve this problem. • Guidance aids can help in reducing driver fatigue by having a reference right in front of the driver rather than in the field somewhere. Benefits of using a Lightbar • Allows the operator to focus more on other machine operations and displays. • Most lightbar systems will record the path of the machine and some even have the capabilities of recording a coverage path indicating whether the machine was applying the product or not. Benefits of using a Lightbar How would I determine where my next pass should be without skips or overlaps? Set-Up and Use of a Lightbar • To operate a lightbar the operator must input basic machine/implement parameters such as width and an operation being performed (not always necessary but is good to have for records). • The operator then steers the first pass through the field creating an A-B line by pushing a button to set “A” at the beginning of the pass and “B” at the end of the pass. • The computer records the locations of the points and then uses the implement width to create subsequent parallel paths across the field. Set-Up and Use of a Lightbar • The operator must be alert to perform the headland turns and realign the vehicle on the next pass. • The off-line distance or error is compared to the actual vehicle location and calculated guidance paths and is displayed on the screen in conjunction with the lighted LED’s showing the operator which direction to steer to. Set-Up and Use of a Lightbar • The simplest lightbar displays are made of a single horizontal row of lights. • The center light indicates the guidance path. • There are many variations in displays systems: – Single row of lights – Double row of lights – LCD display screen w/ 2-D representation of the field and guidance paths. Set-Up and Use of a Lightbar • Some of the earliest systems were only able to create straight parallel swaths. • However, most of the more modern systems have the capabilities to guide along curved paths. • The more modern systems can also follow other various field patterns such as contour strips, irregularly shaped fields, and circular patterns for center-pivot irrigated fields. Set-Up and Use of a Lightbar • Guidance paths are independent of any obstacles in the field, thus the operator must still be alert for these because the system will not warn you of them unless you have previously marked them. • This means if you have an obstacle such as a tree, fence post, or hole you can drive around it and still realign on your path. • Some of the path options have “adaptive” curves that compensate for driving around an object in a field. Set-Up and Use of a Lightbar • The paths can be set up to follow most irregularities in a field such as terraces or contours. • As with any guidance system it is very important for the operator to remain alert during operation to prevent damage to the machine or implement. Set-Up and Use of a Lightbar Common Lightbars and Relative Prices Lightbar Name Outback S-Lite Cost ~$800 TopCon System 110 Raven RGL Lightbars $815-$1120 Raven Cruizer $1,695 Raven Cruizer II $1,695 Trimble EZ Guide 250 ~$1500 Trimble EZ Guide 500 Trimble CFX-750 AgGPS FmX integrated Display Ag Leader L160 Lightbar Ag Leader Edge Ag Leader GPS 1500 $395 $2,195 $995 Conclusions • There are many different types of GPS devices available on the market. • Each of these devices has its own specific use and performs well at its designed task. • As long as you know your needs you should not have a problem selecting the right system. • The right system can have many benefits for most any agricultural operation. Questions???