Presentation

advertisement

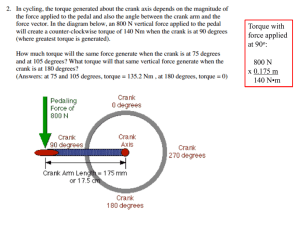

EVALUATION OF JOINT LOADS IN PUSHING / PULLING ATTENDANT-PROPELLED WHEELCHAIRS DURING FORWARD WALKING ON UPWARD AND DOWNWARD SLOPES Tatsuto Suzuki, Maizuru National College of Technology, Japan Hironobu Uchiyama, Kansai University, Japan Catherine Holloway, University College London, UK Nick Tyler, University College London, UK Background The pushing and pulling cart are well met tasks in daily life. Typical pushing and pulling wheel carts - Attendant propelled wheelchair (80kg) - Shopping cart (30kg) - Baby pushchair (25kg) - Medical stretcher (140kg) - Trolley aboard aircraft (85kg) - Industrial cart (up to 400kg) Workload factors Provided capability by person Attendant - Push/pull performance - Age - Gender Required capability by wheelchair and environments Wheelchair - Weight - Rolling resistance - Dimensions Environment - longitudinal and cross slopes - Kerbs - Gaps - Roughness of road surfaces Problems 1. Pushing/pulling is very hard task 2. Pushing/pulling is a known risk factor for musculoskeletal disorders (Back pain, joint strain, sprains) 3. Cause of musculoskeletal disorders - Peak and cumulative forces - duration and repetition, - Continuous tense non-neutral posture Objectives 1. How hard are pushing/pulling tasks? -> How large is the required capability in power? 2. How to adapt push/pull style against the increase of load? -> How to change push/pull posture? 3. How hard are shoulder and elbow? -> How large are the joint torque in shoulder and elbow? Methodology 1. Change slope angles Longitudinal slope angle:+00, +6.5%, +9%, and 12% 2. Change the weight of a wheelchair Wheelchair weight: 36Kg + 00, 20, 40, and 60kg 3. Subjects Ablebodied five patiripants Average age: 33years old Longitudinal slopes UCL Pamela platform - Each plate size: 1200 x 1200mm - Maximum height difference: 300mm - Slope conditions: 0%, 6.5%, 9.0%, 12% 12% 0% 9.0% 6.5% Attendant propelled wheelchair Force measurement: 6-axis load cell at both grips Velocity measurement: Rotary encoder at both wheels Main specifications Wheelchair weight: 36kg Grip height: 0.95m Additional weight: +00, +20, +40, +60kg Joint position measurement Two dimensional measurement - One camera and reflective markers - Marker tracking software Joint torque calculation Figure 1 (a) Experimental system with seven link model to analyse joint torques. (b) Each link difinition in multibody dynamics Joint torque calculation M iq˙˙i - Fqi li = gi System mass matrix: Mi = diag [mi, mi, μi ] System state vector: qi = [xi, yi, ϕi ] External force vector: gi = [gexi, geyi - mig, geni ] Jacobian matrix: Φqi = [1 0; 0 1; -(yPa-yi) (xPa - xi ) ] Reaction force vector by constraint: λi = [λxi, λyi ] The external force vector gi was described next equation. gexi = fxi - λx(i-1) geyi = fyi - λy(i-1) (2) geni = τa – τb + (rPb - ri ) x [gxi, gyi ]T where, the subscript i of each variables is link number. Change of push/pull force and velocity Figure 2 Averaged propelling forces and wheelchair velocities in ascending and descending under four weight and slope conditions. Change of push/pull force and velocity Heavy load Light load Heavy load Figure 2 Averaged propelling forces and wheelchair velocities in ascending and descending under four weight and slope conditions. Push/pull power Push/pull power Heavy load Light load Heavy load Posture in push/pull (a) (b) (c) Figure 3 The difference of propelling postures during stance phase.(participant one) (a) Propelling at a level. (b) Ascend propelling at +9.0%. (c) Descent propelling at -9.0%. Each first frame is the beginning of the stance phase, and last frame is the end of the phase. The time interval between two frames is 25% of the phase. All weight conditions are W = 60kg. Posture in push/pull Lean forward Light push (a) Lean Backward Heavy push Heavy pull (b) (c) Figure 3 The difference of propelling postures during stance phase.(participant one) (a) Propelling at a level. (b) Ascend propelling at +9.0%. (c) Descent propelling at -9.0%. Each first frame is the beginning of the stance phase, and last frame is the end of the phase. The time interval between two frames is 25% of the phase. All weight conditions are W = 60kg. Joint angle in shoulder and elbow Figure 4 Averaged shoulder and elbow angle during stance phase. The joint angles were measured based on the medical definition. Joint angle in shoulder and elbow Extension with the increase of load Flexion with the increase of load Figure 4 Averaged shoulder and elbow angle during stance phase. The joint angles were measured based on the medical definition. Joint torque in shoulder and elbow Figure 5 Averaged shoulder and elbow torque during stance phase. The calculation was carried out with the model in Figure 1. Joint torque in shoulder and elbow Push: Shoulder torque increased Push: Low shoulder torque Large pull torque Elbow torque increased Figure 5 Averaged shoulder and elbow torque during stance phase. The calculation was carried out with the model in Figure 1. Discussions 1. Maximum workload at push/pull around 60W - The same as electric bulbs! - Over 60W in required capability is quite hard to push/pull Discussions 2. Posture Change with the increase of load - lean forward (Push) - lean backward (Pull) - Need to keep balance to apply push/pull force 3. Joint torque in shoulder and elbow - Shoulder in push is harder than in pull - Elbow in pull is harder than in push - Elbow in pull on 12% slope is quite hard Future works 1. Calculate joint power 2. Assisting system for attendants!