Modelling of deformation of different layers during the AFP

advertisement

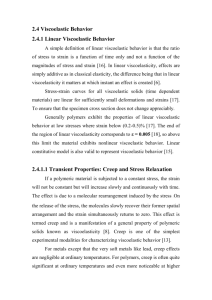

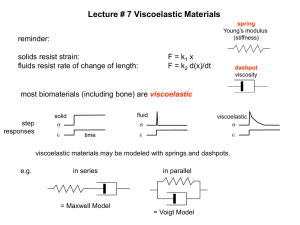

MODELING OF DEFORMATION OF DIFFERENT LAYERS DURING THE AFP PROCESS. P R E S E N T E D B Y: H O S S E I N G H AY O O R S U P E R V I S E D B Y : D R . S U O N G V. H O A INTRODUCTION • • • • Viscoelastic properties Different properties of each layer Effect of time and temperature Understanding of residual stress and final state of material after manufacturing INTRODUCTION Different Temperature Last Layer Different Properties Viscoelastic Problem Layer 3 Layer 2 Layer 1 Mold Figure From: Analysis of Process-Induced Residual Stresses in Tape Placement, F. Sonmez, H. T. Hahn, M. Akbulut, J. of Thermoplastic Composite Materials, 2002 VISCOELASTIC PROPERTIES OF CARBON-PEEK • Creep Properties of PEEK • Carbon fiber remains elastic Figure From: Characterization and modeling of nonlinear viscoelastic response of PEEK resin and PEEK composites, X.R. Xiao, C.C. Hiel, A.H. Cardon, Composite Engineering, 1994 VISCOELASTIC PROPERTIES OF CARBON-PEEK VISCOELASTIC PROPERTIES OF CARBON-PEEK The increase in number of unit cell columns (horizontal) Five by five block of unit cell minimizes the effect of boundary conditions The increase in number of unit cell rows (vertical) VISCOELASTIC PROPERTIES OF CARBONPEEK Creep/ Relaxation Properties of CarbonPEEK composite HOMOGENIZED PROPERTIES OF CARBONPEEK 1.80E-07 1.60E-07 Creep Properties (1/Pa) C22 1.40E-07 1.20E-07 1.00E-07 8.00E-08 6.00E-08 4.00E-08 2.00E-08 0.00E+00 0 10000 20000 30000 40000 Time (s) 50000 60000 70000 Figure From: A thermoviscoelastic analysis of process-induced internal stresses in thermoplastic matrix composites, Sunderland P., Yu W., Manson J., Polymer Composites, 2001 VISCOELASTIC FINITE ELEMENT Formulation: i t Cij (T , t j d N t i 0 k exp j d k 1 k t t i BT Cij (T , t B v j d dv NEW BOUNDARY CONDITIONS Attaching the nodes in the stiffness matrix MULTI-LAYER • Each 8-noded viscoelastic element can represent a unit cell (computational time is many times less) • Different Scenarios can be analyzed • Timing, thickness, temperature can be changed in the analysis TYPICAL ANALYSIS RESULT two-step constant stress (one layer) One-step constant stress (one layer) TYPICAL ANALYSIS RESULT Maximum Strain One-step ramp stress (one layer) Time(s) TYPICAL ANALYSIS RESULT Maximum Strain Strain in the first layer (ramp stress) Depositing second layer Time(s) TYPICAL ANALYSIS RESULT Maximum Strain Strain in first layer (ramp stress) third layer deposited Second layer deposited Time(s) fourth layer deposited fifth layer deposited CONCLUSION • Residual Strain/Stress can be predicted and can be used in manufacturing design to optimize the design. • With developed modeling method different Scenarios of Manufacturing in terms of Timing, Thickness can be modeled and analyzed. THANK YOU!