Viscoelasticity

advertisement

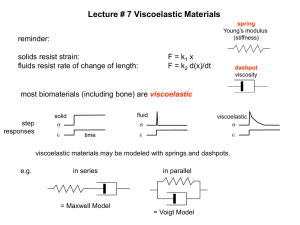

VISCOSITY Plastic deformation occurs by dislocation motions in crystallic structures. For noncrystallic structures plastic deformations are due to viscous flow. The characteristic property for viscous flow, viscosity, is a measure of a noncrystalline material’s resistance to deformation. Plate A F L V When a tangential force (F) acts on the plate, the plate moves with respect to the bottom. The velocity of the liquid particles in each layer is a function of the distance L. Thus the rate at which the particles change their position is the measure of the rate of flow. velocity gradient dV dL = dγ dt rate of flow dV Newton expresses: F = η A dL Since τ = F / A η : coefficient of viscosity 1 τ = η dV dL & τ=η dγ dt 2 Unit of viscosity is Pa.s (Pascal-seconds) (N.s/m2) The liquids that follow equations (1) & (2) are termed as Newtonian Liquids. Newtonian liquids η Viscosity also varies with temperature. A: Constant 1 = A . e-E/RT η E: Energy of activation R: Gas constant T: Absolute temperature When solid particles are introduced into Newtonian liquids, viscosity increases. 1) η = η0 (1+2.5 Ø) η0: Coefficient of viscosity of the parent liquid. 2) η = η0 (1+2.5 Ø + 14.1 Ø2) Ø: Volume concentration of suspended particles NON-NEWTONIAN MATERIALS In certain materials, τ-dγ/dt does not obey the linearity described by Newton, i.e. Viscosity may vary with the rate of shear strain. Dilatant: η increases Newtonian with increasing dγ/dt or τ (clay) η Newtonian: (all liquids) Pseudoplastic: η decreases with dγ/dt or τ (most plastics) The relationship between dγ/dt & τ can be described by the following general equation. dγ = τn . 1 η dt If n=1 → Newtonian n > 1 → Pseudoplastic n < 1 → Dilatant Fresh cement pastes & mortars, have highly concentrated solid particles in the liquid medium. Such a behaviour is described by Bingham’s equation. τ = τy + η dγ dt dγ dt τy τ (Upto τy there is no flow) VISCOELASTICITY & RHEOLOGICAL CONCEPTS Viscoelastic behaviour, as the name implies, is a combination of elasticity & viscosity. Such a behaviour can be described by Rheological Models consisting of springs (for elasticity) & dashpots (for viscosity). Load (Load) t0 Strain Strain t1 Time (Elastic) ε = σ/E t0 t0 Strain t1 t1 Time Time (Viscous) dε/dt = σ/γ (Viscoelastic) t0 t1 Time Models to explain the viscoelastic behavior: • Maxwell Model • Kelvin Model • 4-Element Model (Burger’s Model) 1. Maxwell Model: σ A spring & a dashpot connected in series. k=E β = 1/η σ The stress on each element is the same: σspring = σdashpot However, the deformations are not the same: εspring ≠ εdashpot When the force (stress) is applied the spring responds immediately and shows a deformation εspring = σ/E At the same time the dashpot piston starts to move at a rate βσ = σ/η and the displacement of the piston at time t, is given by: dashpot dt dt 0 0 t t Therefore the total displacement becomes: t spring dashpot dt E 0 t P ε εdashpot εspring t εdashpot→ viscous permanent def. Relaxation: An important mode of behavior for viscoelastic materials can be observed when a material is suddenly stroked to ε0 & this strain is kept constant. σ ε σ0 ε0 t Instead of this loading pattern strain is kept constant. t spring dashpot d d s d d dt dt dt & d 1 d dt E dt If ε is constant → d E dt d s 1 d s E dt E dt d d dt d 1 d 0 0 dt E dt Solving this differential equation 0 .e E t Where : σ0 = Eε0 ε t rel ε0 E Relaxation time is a parameter of a viscoelastic material. t If the body is left under σ σ0 Slope @ t=0 0.37σ0 trel t a constant strain, the stress gradually disappears (relaxes). This pehenemenon can be observed in glasses & some ceramics. 2. Kelvin Model: Consists of a spring & a σ 1/η E σ dashpot connected in parallel. In this case the deformations are equal but the stresses are different. εspring = εdashpot σspring ≠ σdashpot σ = σspring + σdashpot E. spr d dash . dt σ d E dt σ0 t E t 0 d 1 e E E dt E ε (Delayed elasticity) t At each strain increment the spring will extend by σ/E so that a part of the load is taken over and the force on the piston decreases. Thus a final displacement is reached asymtotically and when the load is removed, there will be an asymtotic recovery until σ=0. When a viscoelastic Kelvin Body is subjected to a constant stress, σ0, the response could be obtained by solving the differential equation. 0 E 1 e E t 0 is reached at σ E time t=∞ t ret t ε 0 E retardation time When stressed the elastic deformation in the spring is retarded by the viscous deformation of the dashpot. ε0 0.63ε0 Retarded elastic strain (delayed elastic strain) E tret 3. Burger’s Model: The actual viscoelastic behavior of materials is very complex. The simplest models, Maxwell & Kelvin Models, explain the basic characteristics of viscoelastic behavior. The Maxwell Model, for example, has a viscous character and explains the relaxation behavior of viscoelastic materials The Kelvin Model on the other hand has a solid character and explains the retarded elasticity behavior. However, none of the mentioned models completely explain the real behavior of viscoelastic materials. There are other models with different E and η constants but they are rather complex. One such model is given by BURGER, which consists of a Maxwell Model and Kelvin Model connected in series. σ σ σ0 E1 t η1 η2 E2 σ εvis+εret ε ε1 ε1 t εvis E2 t 0 0 0 t 1 e 2 E1 1 E2 Spring Dashpot (elastic) (viscous) Kelvin (retarded elasticity) Most engineering materials show certain deviations from the behavior described by the 4-Element Model. Therefore the deformation equation is usually approximated as: E k 1 e Instantaneous elastic Retarded elastic qt n t Viscous Where “k, β & γ” are material constants & “α, n” are constants accounting for nonlinearity. 1 k E q 1 t ret E 1 Example 1: For a certain oil, the experimentally determined shear stress, rate of flow data provided the following plot. Determine the viscosity of the oil. d 1 dγ/dt (1/sec) d dt 0.9 dt 0.6 20 N 33.3 2 sec . 0.6 m 0.3 10 20 30 τ (Pa) Example 2: When a concrete specimen of 75 cm in length is subjected to a 150 kgf/cm2 of constant compressive stress, the following data were obtained. t (month) ε B. .t where B is constant. Assume 0 0.0006 1 0.0007 E What will be the total deformation under 150 kgf/cm2 after 6 months? @t 0 E 0.0006 1 10 4 @ t 1 0.0007 0.0006 B.150.1 B 150 1 10 4 @ t 6months 0.0006 150 6 0.0012 150 Example 3: A glass rod of 2.5 cm in diameter & 2.5 m in length, is subjected to a tansile load of 10 kgf @ 450°C. a) Calculate the deformation of the rod after 100 hrs. b) Determine trel (relaxation time) c) What is the time during which the stress in the material would decay to 5% of its initial volume? η=2x1012 poise @ 450°C & E=1.55x105 kgf/cm2 Assume that the behavior of glass at this temperature can be approximated by a Maxwell Model. a) For Normal Stresses & Strains the viscous behavior is described by dε/dt=σ/λ where λ is called “the Coefficient of Viscous Traction” & equals to “3η”. 10kgf 2.5 4 2 2.04 kgf cm 2 η=2x1012 poise (1 poise = 1 dyne.sec/cm2) & (1 kgf = 106 dyne) d 2.04 10 dyne 7 1 3 . 4 10 sec dt 3 3.2 1012 poise 6 After 100 hrs the total strain is 3.4x10-7x100x60x60 = 0.1244 Δ = 0.1244x250 = 30.6 cm