EdgeCAM Waveform Data - Manufacturing Technologies Group

advertisement

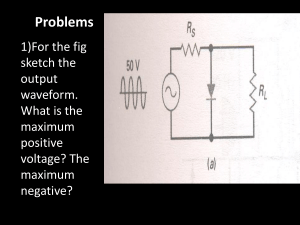

:Waveform Event Vero Software Limited Hadley House, Bayshill Road, Cheltenham, Gloucestershire, GL50 3AW, UK Page 1 Waveform Agenda • • • • Introduce Edgecam Waveform Technology Edgecam Waveform Testing Where to find Edgecam Waveform data Q&A Page 2 Unlocking Your Machines Potential Page 3 Unlocking Your Machines Potential Higher Feedrates! At deeper Depths! Page 4 Maximum RPM! Think About Every Part You’ve Cut How deep can I cut? How fast can I cut? How much stepover can I take? Page 5 Deeper… After all, if you cut in a straight line, you can machine … At higher RPM… WHY? With a larger stepover… And FASTER!!! Page 6 (video) Traditional Toolpath Review Page 7 Straight line vs. corners •The challenge with traditional toolpath / shape offset machining Material Engagement 50% of Cutter 100% of Cutter 10mm End Mill at 50%=5mm Page 8 10mm End Mill at 100%=10mm 180 Degree Engagement Feedrate Override!! Page 9 Traditional vs Waveform Page 10 Edgecampedia Waveform This new roughing strategy is a high speed machining technique that maintains a constant tool cutting load by ensuring the tool engagement into the material is consistent. The tool path moves in a smooth path to avoid sharp changes in direction which maintains the machine tool’s velocity. change in velocity acceleration = time Page 11 Edgecampedia Waveform Pattern • Helical plunges into pocket • Imitates straight line cutting • Maintains constant chip load • Reduces intermittent cuts • Tool is engaged with material longer without lifting • Reduces Cycle Times • Smooth tangent toolpath •Reduces wear and tear on tools, holders, and machine •Works with 2D or 3D Roughing Page 12 Edgecampedia Waveform Properties • Deeper Depth of Cut (DoC) • Use full Flute Length 20% WoC • Manages Width of Cut (WoC) • Controls Chip Thickness • Generating Faster Feedrates •Constant Feedrate DOC = 2.5 x Tool Diameter • Superior Speeds •Consistent Tool Load Page 13 Edgecampedia Automatically Adjusts • Maintains consistent material removal by adjusting width of cut • Maintains chip thickness and chip load • Concave areas • Width of cut decreased • Convex area • Width of cut is increased Page 14 Edgecampedia Waveform Links • Links are aware of rapid and High Feedrates • Waveform uses fastest method • Localized areas stay at depth • Long Links retract and rapid Page 15 New in 2012 R2 Waveform Enhancements • Tapered Helical Plunge •3 Degree Taper • Percent Speed adjustment for Helical Plunge • Optimized Mill Type •Alternates Climb/Conventional • Improvements to Arc Tangency Page 16 Edgecampedia Waveform Ease of Use • Uses standard Roughing Cycle • Simple Interface • 3 Modifiers To Adjust • Minimum Radius can also be used Page 17 The Hard Part Getting Started “Not on my machine you don’t!!” •Finding machine time •Test straight line test cutting •Run until tool breaks and back off 20% •Add Test Data in Waveform Cycle •DO NOT Adjust Feedrate Override during cycle •Slowing down will burn up cutter “Wow, I didn’t know my machine could do that!!” Page 18 Waveform Test Traditional Toolpath Tool Size RPM Feed DOC %Step Cycle Time 16mm 2600 1000mm/Min 5mm 30% 63 min Waveform Toolpath Tool Size RPM Feed DOC %Step Cycle Time 16mm 5000 3000mm/Min 20mm 18.5% 18 min Machine: Mazak Vertical Centre Smart 430 A Material: P20 Tooling Provided Courtesy of Sandvik Cycle Time Reduce By: 45 min = 71% Page 19 Waveform Test Traditional Toolpath Tool Size RPM Feed DOC %Stepover Cycle Time .500 4FL .06R 1500 16 ipm .125 30% 42:32 Waveform Toolpath Tool Size RPM Feed DOC %Stepover Cycle Time .500 4FL .06R 10,000 196 ipm 1.00 18% 4:15 Machine: Mori Seiki MV-653 Material: 4140 Rc: 28-36 Cycle Time Reduce By: Tooling Provided Courtesy of Sandvik 38 min = 90% Page 20 Waveform Live Page 21 Waveform Data Page 22 Waveform Data Sheets Page 23 Questions Page 24 Questions I ran Waveform at the same feeds and speeds with my usual settings and it wasn’t any faster. Why? Waveform was designed to cut significantly faster and deeper than traditional toolpaths. If you run at the same parameters (Spindle Speed, Feedrate, Axial Depth of cut, Radial Depth of Cut) as with traditional toolpaths, you are driving a Ferrari at Yugo speeds. Run Waveform toolpaths to their capability and it will be unbelievably faster. Page 25 Questions Does Waveform require specialized tooling? Reviewing your entire process, such as tooling, work holding, and coolant will bring further cycle time benefits. When using your existing tooling, Waveform users will see improvements in cycle time, tool life, and machine maintenance cycles. Page 26 Questions Does Waveform require higher-end/highspeed machines with expensive options? No, some of the largest performance increases to date have been realized on older basic machines. Waveform toolpaths can be run much faster and deeper than any traditional toolpaths due to constant tool load. Page 27 Questions I’m a job shop and I don’t run production. Most parts are one off’s. How will I benefit from Waveform? Waveform users can quote lower machine rates compared to non users or charge the same rates and run more hourly jobs per week/month/year. Not to mention extended tool life from constant tool load and reduced machine maintenance cycles. Page 28 Questions Will I only see cycle time improvements in Aluminum parts? Actually, Waveform is even more impressive in hard materials. Overloading the tool is much more severe in harder materials than in softer materials. Since Waveform never overloads the cutting tool, hard materials can be cut at very aggressive material-removal rates. Page 29 Questions Why doesn’t Waveform adjust feedrates? Other CAM systems that provide toolpath similar to Waveform, do no adjust engagement in convex and concave corners. This giving Waveform an upper hand. Since constant chip thinkness is calculated through corners, no feedrate adjustment is required. Waveform either reduces it’s % stepover or increases depending on the cut. Page 30 : Thank you Questions? Page 31