Tuffy Bike - Columbia Business School

advertisement

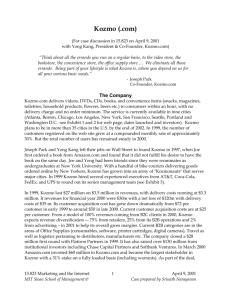

B7801: Operations Management 24 March 2000 • • • Burger King & McDonald’s Tuffy Bike Queuing fundamentals p. 1 By Greg Sandoval Staff Writer, CNET News.com March 21, 2000, 12:25 p.m. PT update Kozmo.com, the online convenience store that promises to deliver goods in less than an hour, filed today to raise $150 million in an initial public offering. New York City-based Kozmo sells entertainment, food and household products online and dispatches delivery people in vans, on bicycles and on motor scooters to carry the purchases to customers' doors. The IPO filing follows an announcement yesterday by Amazon.com that it invested $60 million in a private round of financing for Kozmo and signed a three-year agreement to ship some entertainment items to customers via Kozmo. The public filing showed that Amazon owns a 31 percent stake in Kozmo, which intends to use the IPO proceeds to fund expansion to at least 10 new cities this year. Among the company's other investors are Chase Capital Partners, Oak Investments and Flatiron Partners. Analysts have predicted that Kozmo, which operates in six U.S. cities including New York, San Francisco and Los Angeles, will gain a foothold in the same-day delivery business. Amazon ships most of its goods through the U.S. Postal Service, an Amazon spokesman said yesterday. Kozmo's SEC filing provided few surprises about the company, founded by co-chief executives Joseph Park, 28, and Yong Kang, 27. Like so many other Internet companies, Kozmo is experiencing huge growth as its losses mount. The company is recording a 30 percent rise in new customers each month, but it has accumulated a $27 million deficit. In a deal announced this month, Kozmo agreed to pay Starbucks about $150 million during the next five years for the right to offer the giant coffee merchant's products on its site. As for its short-term prospects, Kozmo said in the public filing, "We expect that we will continue to incur substantial losses for the foreseeable future." p. 2 Purposes of process flow analysis • Document the process – – • Assess basic performance measures – – – – • What gets done? Where? By whom? In what sequence? Cost Capacity Inventory Throughput time (delay) Identify bottlenecks and improvement opportunities p. 3 1) Capacity (per time) = maximum sustainable output per unit of time = (# produced per cycle)/(cycle time) Ex: Calculating capacity of a batch process - batch of 36 parts (lot size = 36) - 6 hours to run a batch - 1 hour of set-up/batch set-up 1 hr. run set-up run set-up run 6 hrs. # parts/batch Capacit y cycle timeof batch 36 parts/batch 5.14 parts/hr. 1 6 hrs./batch p. 4 Actualoutput per time 2) Utilization 100% Capacityper time Ex (cont): - batch process produces 35 parts/day - 8 hrs./day production time What is the utilization? actual# parts/time Utilization capacity 35 parts/day x 100% 85.1%. (5.14 parts/hr.) x (8 hrs/day) p. 5 3) Bottleneck = the resource that limits the capacity of the overall process Why are bottlenecks important? (The Goal) p. 6 4) Cycle stock = the average inventory level resulting from batch production or ordering = 1/2 x (batch or lot size) Ex: Produce a batch of 36 parts every 7 hours. Demand = Production = 36/7=5.14 parts/hr. What is the average cycle stock? inventory slope = - 5.14 36 18 0 time t t+7 t+14 t+21 Average inventory (cycle stock) = 1/2 x 36 = 18 parts NOTE: Increasing the lot size increases cycle stocks for the same production rate. p. 7 5) Little’s Law Relates avg. throughput time (delay), inventory and production rate N averageinventorylevel W average throughput time(avg.delay) averageproductionrate Little’s Law says …. N W That is, given any two of these measures of performance, the remaining one is uniquely determined. p. 8 Ex (cont.): Produce a batch of 36 parts every 7 hours. Demand = Production = 36/7=5.14 parts/hr. Q:What is the delay (throughput time) at this stage of production? A: From before, we know the average cycle stock is 18, so N=18. The production rate is = 5.14 parts/hr. So by Little’s Law, the average throughput time is W = N/ = 3.5 hrs. Ex: Bread is produced at a rate of 7,000 loaves/hr. Loaves take 20 min. to cool on the cooling rack. Q:How many loaves must the cooling rack hold? A: We know that the average time to cool is W=20 min. = 1/3 hrs. The production rate is given as = 7,000 loaves/hr. So by Little’s Law, the average number of loaves in the cooling rack is N = W = 7,000/hr. x 1/3 hrs. = 2,333 loaves. The cooling rack must hold at least this many loaves. p. 9 Throughput vs. Cycle Time: Lincoln Tunnel Example Case 1: W=20 min. throughput time = 20 min. N = 2 cars = 0.1 cars/min. cycle time = 10 min. Case 2: W=20 min. throughput time = 20 min. N = 20 cars = 1 car/min. cycle time = 1 min. p. 10 Throughput time vs. cycle time • Cycle time – – – The time between completion of units The inverse of production rate (for unit production) Answers the question: • • How much time is there between each car that is exiting the tunnel? Throughput time – – – The time an individual units spends in the system. Also called waiting time, sojourn time, flow time Answers the question: If you painted an arriving car orange and put it in the tunnel, how much time would elapse before the orange car exited the tunnel? p. 11 Tuffy Bike • • • Customized bicycles Demand: 600 units/month, $750/unit; 20% increase next year Work force – – – – • 3 supervisory workers, $50,000 each 13 hourly production workers, at standard rate $18/hr 6 hourly skilled production workers (welders) at $30/hr 8 hr shift, 5 days/wk, 48 weeks/yr Operating expenses – – Rent, insurance, utilities, etc.: $20,000/month Materials costs: $550/unit p. 12 Tuffy Bike: Basic steps tube stock cutting welding ship assembly painting p. 13 Tuffy Bike (continued) • Cutting and finishing – • Welding – – • – 3 workers, standard rate, 30 minutes/unit 8 hours drying time/unit Assembly – • 6 skilled workers, $30/hr, 45 minutes for setup, 45 minutes welding On average, 250 units waiting to be welded Painting – • 3 hourly workers, standard rate, 30 minutes/unit 7 workers, standard rate, 90 minutes/unit Shipping – 7 days, $25/unit p. 14 Waiting Time Calculation cutting WIP welding waiting! 250 units rate: 600 units/month = 30 units/day waiting time = 250/30 = 8.3 days Throughput time for Tuffy Bike = 8.5+8.3 = 16.8 days p. 15 Tuffy Bike current process order database dealer phone orders from dealers tube stock inv. shipping 7 days $25/unit component inv. cutting 3 workers 30 min. cycle 6 frames/hr cut frame WIP 250 units avg welding 6 workers 45 min set-up 45 min welding 4 frames/hr ($30/hr) painting 3 workers 30 min cycle 6 frames/hr drying WIP 8 hrs drying time 30-40 units avg. final assembly 7 workers 90 min cycle 4.67 frames/hr Demand: 600 units/mo. (160 hrs/mo. Production) Assets: 1 month of receivables $1M in plant & equipment (Other data see note.) p. 16 Operating Profits 600 units/month X 12 months X $/unit Rev/Unit Mat.&Comp. Gross Margin $ $ $ 750.00 (550.00) 200.00 Cut Labor $ Weld Labor $ Paint Labor $ Assemble Labor$ Shipping $ Contrib. Marg. $ (9.00) (45.00) (9.00) (27.00) (25.00) 85.00 Annual Revenue$ 5,400,000 Mat.&Comp. $ (3,960,000) Labor $ (648,000) Shipping $ (180,000) Net Contrib. $ 612,000 Super. Labor $ (150,000) Rent & Equip $ (240,000) Oper. Profit $ 222,000 100.0% -73.3% -12.0% -3.3% 11.3% -2.8% -4.4% 4.1% p. 17 Tuffy Bike: Base Case Mon. Prod. Prod. Rate Batch Size cut weld paint assemble set-up (min) 0 45 0 0 Income Rev/Unit Mat.&Comp. Gross Margin 600 unit/month 3.75 units/hr. 1 units cycle (min) total min./unit 30 30.0 45 90.0 30 30.0 90 90.0 $ $ $ 750.00 (550.00) 200.00 Cut Labor $ Weld Labor $ Paint Labor $ Assemble Labor $ Shipping $ Contrib. Marg. $ (9.00) (45.00) (9.00) (27.00) (25.00) 85.00 Annual Revenue$ 5,400,000 Mat.&Comp. $ (3,960,000) Labor $ (648,000) Shipping $ (180,000) Net Contrib. $ 612,000 Super. Labor $ (150,000) Rent & Equip $ (240,000) Oper. Profit $ 222,000 (600 units/mo. / 160 hrs/mo.) $/hr. $18.00 $30.00 $18.00 $18.00 $/unit $9.00 $45.00 $9.00 $27.00 $90.00 #workers 3 6 3 7 Leadtime (working days) Welding WIP 8.3 Processing 1.5 Transport 7 Total 16.8 cap. (#/hr.) 6.00 4.00 6.00 4.67 utilization 63% 94% 63% 80% (1) (2) (1) Caculated in case: N=250 units in inventory divided by production rate of 30 units/day. (2) 4 hrs of processing time + 8 hrs of drying time Inventory #units Orders Cut Frames Welded Frames Painted Frames Finished Goods 100.0% -73.3% -12.0% -3.3% 11.3% -2.8% -4.4% 4.1% cost/unit 0 250 0 0 0 $ $ $ $ Total 0 559.00 604.00 613.00 640.00 cost $ $ 139,750.00 $ $ $ $ 139,750.00 (1) (1) 250 units given Assets Accts. Rec. Inventory Plant & Equip Total Assets ROA $ 450,000 $ 139,750 $ 1,000,000 $ 1,589,750 14% (1 month of sales) p. 18 Tuffy Bike: Batch production scenario 1) Product variety: 2 2 2 5 5 200 lengths heights wheel diameters color schemes equipment packages (assembly options) Total Variants 2) Assume all 200 variants are equally popular (unrealistic but simple) p. 19 Tuffy Bike: Batch production scenario 3) Produce in batches (lots) of 30. Batch production data: set-up (min.) cut 30 weld 45 paint 120 assembly 120 cycle time (min.) 25 45 20 70 4) Assets 1 month of receivables $1M in plant and equipment p. 20 Is this alternative any better? Issues to consider: • Unit cost • Capacity/bottlenecks • Throughput time (leadtime to customers) • Product variety • Level of investment (inventories) • ROA p. 21