CETA Logo

advertisement

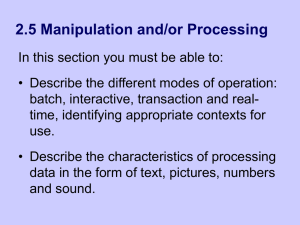

Level 1 Business Studies 1.1 - AS90837 Demonstrate an understanding of internal factors of a small business Production Process Students will identify and understand the methods and costs relating to production: Indentify the methods of production, i.e. job, batch and flow Describe the advantages and disadvantages of each one. What is Production? Production means the development and creation of goods and services using resources. It is the physical output of a manufacturing or service company. Production involves three processes – raw materials, work in process and finished goods. Methods of Production Job Production Batch Production Flow Production Job Production Job production, involves producing a one-off product for a specific customer. Job production is most often associated with small firms but large firms use job production too. Source: http://en.wikipedia.org/wiki/Job_production Job Production Examples: 1. 2. 3. 4. 5. making railings for a specific house, building repairing a computer for a specific customer making flower arrangements for a specific wedding designing and implementing an advertising campaign building a new factory Advantages of Job Production 1. 2. 3. 4. work is generally of a high quality a high level of customisation is possible to meet the customer's exact requirements significant flexibility is possible, especially when compared to mass production workers can be easily motivated due to the skilled nature of the work they are performing plus variety of work. Disadvantages of Job Production 1. 2. 3. higher cost of production (often labour intensive) requires the use of specialist labour (compare with the repetitive, low-skilled jobs in mass production) slow compared to other methods (batch production and flow production) Essential Features (Job Production) There are a number of features that should be implemented in a job production environment, they include: Clear definitions of objectives should be set. Clearly outlined decision making process Batch Production Batch production is the manufacturing technique of creating a group of components at a workstation before moving the group to the next step in production. Batch production is common in bakeries and in the manufacture of sports shoes, pharmaceutical ingredients, inks, paints and adhesives. Source: http://en.wikipedia.org/wiki/Batch_production Examples of Batch Production Bakery: produces a batch of white bread, wholemeal bread, rolls etc Furniture Maker: produces dining room furniture, ie a batch of tables, chairs and cabinets Clothes Maker: produces a batch of size 14 shirts, size 12 shirts etc Advantages of Batch Production It can reduce initial capital outlay because a single production line can be used to produce several products. Batch production can be useful for small businesses who cannot afford to run continuous production lines. Provides employees with variety. Advantages of Batch Production (continued) If a retailer buys a batch of a product that does not sell, then the producer can cease production without having to sustain huge losses. Batch production is also useful for a factory that makes seasonal items, products for which it is difficult to forecast demand, a trial run for production, or products that have a high profit margin. Disadvantages of Batch Production There are inefficiencies associated with batch production as equipment must be stopped, reconfigured, and its output tested before the next batch can be produced. Additional storage space is required for stocks of raw materials which can be costly. Idle time between batches is known as downtime. Flow Production When large quantities of a product are produced in a continuous process. Sometimes referred to as mass production. Is the production of large amounts of standardised products, including and especially on assembly lines. Flow Production It is called flow production because products look like they’re flowing down a production line Flow Production Mass production is capital intensive and energy intensive, as it uses a high proportion of machinery and energy in relation to workers. It is also usually automated to the highest extent possible. With fewer labour costs and a faster rate of production, total expenditure per unit of product is decreased. However, the machinery that is needed to set up a mass production line can be so expensive that there must be some assurance that the product is to be successful to attain profits. http://en.wikipedia.org/wiki/Mass_production Advantages of Flow Production Very time efficient Costs and price are able to be kept low resulting in higher sales Generally capital intensive and therefore saves on labour costs Unskilled workers generally required, therefore little training is needed Time saved as no need to move around the factory Goods can be produced quickly and cheaply Disadvantages of Flow Production Can be very boring for workers and provides little job satisfaction Initial set up capital costs can be very high When one machine breaks down the entire production line may have to be stopped.