2-ITK-330 Isothermal Reactor Design - Dicky Dermawan

advertisement

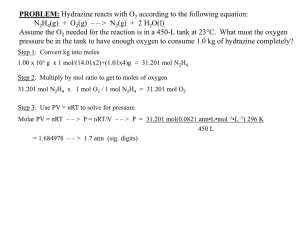

ITK-330 Chemical Reaction Engineering Isothermal Reactor Design Dicky Dermawan www.dickydermawan.net78.net dickydermawan@gmail.com Algorithm for Isothermal Reactor Design Example of Application: First-order Gas Phase Reaction in PFR An Example: Effect of Reactor Type The elementary gas phase reaction 2A+BC with rate constant k=10 L2/mol2.s takes place in a CSTR at constant temperature (500 K) and constant pressure (16.4 atm). The feed is equal molar in A and B. The feed volumetric flow rate vo=25 L/s. In order to achieve 90% conversion: a. Estimate the CSTR volume b. What is the reactor volume if PFR is used? c. How long would it take if the reaction is carried out in a constant volume batch reactor? P4-5A P4-7A General Guidelines for California Problems In the past there have typically been six problems in a three hour segment of the California Professional Engineers Exam. Consequently one should be able to work each problem in 30 minutes or less. Many of these problems involve an intermediate calculation to determine the final answer. 1. Group unknown parameters/values on the same side of the equation example: [unknowns] = [knowns] 2. Look for a Case 1 and a Case 2 (usually two data points) to make intermediate calculations 3. Take ratios of Case 1 and Case 2 to cancel as many unknowns as possible 4. Carry all symbols to the end of the manipulation before evaluating, UNLESS THEY ARE ZERO P4-11B P4-12B Changing Feed Ratio P4-13B Arranging Additional Reactor L5-13: Scale Up Problem (a) The homogeneous gas reaction A 3 R follows secondorder kinetics. For a feed rate of 4 m3/hr of pure A at 5 atm and 350oC, an experimental reactor consisting of a 2.5 cm ID pipe 2 m long gives 60% conversion of feed. A commercial plant is to treat 320 m3/hr of feed consisting of 50% A, 50% inerts at 25 atm and 350oC to obtain 80% conversion. How many 2-m lengths of 2.5 cm ID pipe are required? Should they be placed in parallel or in series? Assume plug glow in the pipe, negligible pressure drop, and ideal gas behavior L5-18: Scale Up & Laboratory Experiment The homogeneous gas reaction A 2B is run at 100oC at a constant pressure of 1 atm in an experimental batch reactor. The data in below were obtained starting with pure A. What size plug flow reactor operated at 100oC and 10 atm would yield 90% conversion of A for a total feed rate of 10 mol/sec, the feed containing 40% inert? Time, min V/V 0 0 1 1 1.2 2 1.35 3 1.48 4 1.58 5 1.66 6 1.72 Time, min V/V 0 8 1.82 9 1.86 10 1.88 11 1.91 12 1.92 13 1.94 14 1.95 7 1.78 P4-14C Similarity: Adaptation, Scale Up etc. P4-15A Similarity: Adaptation, Scale Up etc. P4-16B: Reactor Nonideality Pressure Drop in Packed Bed Reactors Ergun: 0 0 0 P T FT 0 0 P T0 FT 0 Catalyst weight: P T0 FT0 P0 T FT FT 1 X FT 0 Isothermal Fixed (i.e. Packed) Bed Reactors Design Example for First Order Reaction Performance equation: Kinetics: Stoichiometry: Pressure drop: Combine: dX rA dW FA 0 rA Gas k E k k1 exp a R CA CA CA0 1 X P T0 1 X P0 T liquid dP T P 0 (1 X) dW 2 T0 P / P0 dX f ( rA ) f (X, P) dW dP g ( X, P ) g ( X, P ) dW 1 1 T1 T CA CA0 (1 X) for small DP: P/P0 = 1 Thus… The combination results in 2 simultaneous differential equations Polymat 5.0 Introduction to Simultaneous Ordinary Differential Equation Solver P4-18B Example: PBR Design Reforming reactors are used to increase the octane number of petroleum. In a reforming process 20.000 barrels of petroleum are to be processed per day. The corresponding mass and molar feed rates are 44 kg/s and 440 mol/s, respectively. In the reformer, dehydrogenation reactions such as: Paraffin Olefin + H2 occur. The reaction is first-order in paraffin with k’ = 0.02 L/kgcat.s. Assume that pure paraffin enters the reactor at a pressure of 2000 kPa and the corresponding concentration of 0.32 mol/L. This reaction is carried out in a tubular packed bed 2.4 m in diameter and 25 m in length containing 173870 kg catalyst P B R D e s i g n The hydrodemethylation of toluene is to be carried out in a packed bed reactor. Plot the conversion, pressure ratio P/P0, and the partial pressures of toluene, hydrogen, and benzene as a function of catalyst weight. The molar feed rate of toluene to the reactor is 50 mol/min and the reactor is operated at 40 atm and 640oC. The feed consist of 30% toluene, 45% hydrogen, and 25% inerts. Hydrogen is used in excess to help prevent coking. The pressure drop parameter is 9.8x10-5 kg-1. Also determine the catalyst weight in a CSTR with a bulk density of 400 kg/m3 C 6H5 CH 3 H2 C 6H6 CH 4 r ' C6H5CH3 k' 0.00087 k 'PH2 PC6H5CH3 1 K C6H6 PC6H6 K C6H5CH3 PC6H5CH3 mol atm 2 kgcat min K C6H6 1.39 / atm K C6H5CH3 1.038 / atm P4-19B Exercises 1. The first-order homogeneous gaseous decomposition A 2.5 R is carried out in an isothermal batch reactor at 2 atm with 20% inerts present, and the volume increases by 60% in 20 min. In a constant- volume reactor, find the time required to reach 8 atm if the initial pressure is 5 atm, 2 atm of which consist of inerts. Exercises 2. Kinetika reaksi dekomposisi zat A pada fasa larutan dipelajari menggunakan indikator warna yang berubah saat konsentrasi A turun hingga kurang dari 0,1 mol/L. Umpan yang mengandung 0,6 mol A perliter dialirkan ke dalam tangki pertama dari dua reaktor tangki berpengaduk yang disusun secara seri, masing-masing bervolume 400 cm3. Perubahan warna terjadi dalam reaktor pertama pada keadaan tunak saat laju alirnya 10 cm3/menit. Perubahan yang sama baru terjadi di reaktor kedua pada keadaan tunak saat laju alir mencapai 50 cm3/menit. Larutan yang mengandung 0,8 mol A perliter direaksikan dalam susunan reaktor di atas. Berapa laju alir umpan agar dicapai konversi 95%? Exercises 3. The first order reversible liquid reaction: AR CA0 = 0.5 mol/L, CR0 = 0 Takes place in a batch reactor. After 8 minutes, conversion of A is 33.3%, while equilibrium conversion is 66.7%. Find the rate equation for this reaction. Design in Term of other than Conversion In some instance it is more convenient to work in term of NA, NB,… (batch) or FA, FB,… (continue) rather than conversion. Use Rather than dN A rA V dt or dFA rA dV VCSTR FA 0 FA rA NA 0 dX rA V dt dX FA 0 rA dV for each species involved rB b rA a NT N T0 or rc c rA a FT FT 0 Fj P T0 C j CT0 FT P0 T rD d rA a or VCSTR FA 0 only for A da ac ba 1 1 X C j C A0 Θ j j X P T0 1 X P T X rA Working in Terms of Molar Flow Rates in a PFR The gas phase reaction: A 2B is carried out isothermally at 500 K & 10 atm without pressure drop in a PFR and follows an elementary rate law. Determine: a. Equilibrium conversion b. The molar flow rates along the length of a 100 L reactor. c. Reactor volume required to achieve 95% of equilibrium conversion Additional information: kA = 2.7 min-1 KC = 1.2 mol/L FA0 = 10 mol/min Illustration of Application: Semibatch Reactors Mole balances & stoichiometry: dNA 0 0 rA V dt dNB FB0 rA V dt dNC rA V dt dND rA V dt Mass balances: dV 0 dt CC CD Kinetics: rA k CA CB K C Illustration of Application: Semibatch Reactors P4-26B Illustration of Application: Unsteady State Operations Semibatch Reactors P4-27B Illustration of Application: Membrane Reactors Mole balances & stoichiometry: dFA rA dV dFB rB dV dFC rC RC dV rA rB rC Mass transfer: RC k cC CC C6H12 C6H6 H2 A B C Illustration of Application: Membrane Reactors P4-30B Illustration of Application: Membrane Reactors P4-31C