Majid Entezarian

advertisement

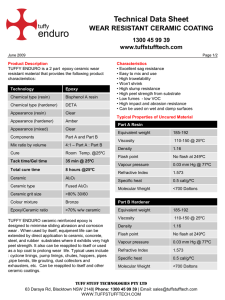

Scaffold Materials and Structures M. Entezarian, Dick Smasal, Brad Heckendorf Phillips Plastics Corporation Methods for making porous structures • Foaming – Limited to polymeric materials – Random pore structure – weak • Replication – Copying geometry and features of precursor structure – Porous metallic and ceramic materials possible • Free-forming – Geometry not limited – Slow • Molding – Mass production Macro reticulated porous ceramic process A. Use reticulated foam of Polyurethane or Polyester, HA or TCP powder, water, and a binder B. Coat the foam with ceramic powder C. Fire B, burn the polymer scaffold and sinter the ceramic powders Solid-free forming A. Prepare formulation (Ceramic + binders) B. Construct the designed 3D structure C. Dry and fire to produce the desired structure Porous beads A. Prepare formulation B. Make beads and fire to obtain porous structure C. use a pack of beads for cell growth Macro reticulated porous ceramic process (Through injection molding) A. Mold porous structures with CIM feedstocks of HA or TCP B. Debind the molded structure C. Fire the structure and produce an ordered porous structure Replication Method Raw Material-Reticulated Foam Macro photograph SEM micrograph Raw Material Ceramic Powder • Materials — any sinterable ceramic: – Hydroxyapatite – Tri-Calcium Phosphate – Zirconia – Alumina Example Hydroxyapatite Powder Manufacturing Process • Preparation of ceramic slip (like paint) – disperse ceramic powder with: • water • polymeric binder • dispersant • additives Manufacturing Process • • • Coat reticulated polymeric foam – cell size of foam used to control ceramic foam cell size Cut desired implant size – 3D geometric features possible Sinter ceramic foam – burn out all organics — foam and slip additives Manufacturing Process “Green” coated foams ready for sintering Manufacturing Process • Sintering – Temperatures of 1000° C to 1600° C – Precursor foam and organics removed – Ceramic powder becomes dense Manufacturing Process Sintered foam parts Chemistry • Hydroxyapatite (Ca5(PO4)6OH) – Meets ASTM F1185 Standard Specification of Ceramic Hydroxyapatite for Surgical Implants • TriCalcium Phosphate (Ca3(PO4)2) – Meets ASTM F1088 Standard Specification for Beta-TriCalcium Phosphate for Surgical Implants Structure • Fully open and interconnected pores • Structure independent of material • Median pore size 264 µm • Narrow and controlled pore size distribution • 80% Porous (nominal) Scanning Electron Micrograph of Hydroxyapatite Physical • Hydroxyapatite – Bulk Density 0.57 g/cc (±0.03) – Porosity 81.1% (±1.01) – Sintered (strut) Density 95% – Crush Strength 1.89 MPa (±0.19) – Modulus 47.1 MPa Physical • TriCalcium Phosphate – Bulk Density 0.51 g/cc (±0.05) – Porosity 83.5% (±1.56) – Sintered (strut) Density 93% – Crush Strength 1.31 MPa (±0.25) – Modulus 39.9 MPa IN VIVO EVALUATION OF BONE SUBSTITUTES IN A RABBIT TIBIAL DEFECT MODEL Hydroxyapatite Start 6 Weeks 8 Weeks Tricalcium phosphate Start 6 Weeks 8 Weeks Alumina Start 6 Weeks 8 Weeks Sintered Dense/Macro Porous Ceramics • • • • Biocompatible Bioresorbable Maintain structural strength Elicit minimal foreign body reaction Study purpose: To compare two injection molded sintered dense ceramics, HAP and TCP,in a rabbit transcondylar femur model. Histologic Results • HAP – Well-defined smooth circumference with thin layer of biofilm. 12 weeks 24 weeks Histologic Results TCP – Rough/irregular circumference with bone ingrowth into implant 12 weeks 24 weeks MOPS Introduction • Produce Porous Ordered Structures of polymers, metals, and ceramics through Injection Molding • 50% porosity • Pore size of 0.020” for polymeric materials • Pore size of 0.016” for metallic and ceramic materials Osteogenic Differentiations Dan Collins, BioE Inc. Chondrogenic Differentiation TCP 7 days TCP 14 days Dan Collins, BioE Inc. TCP 70 days Crush Strength Comparison Crush Stength (MPa) Crush Strength Comparison 120 100 80 60 40 20 0 Ordered Porous Alumina Reticulated Alumina Structure Materials molded in these structures • • • • • • • • • Polyethylene Polycarbonate PEEK PCL (bio-degradable) PLA (bio-degradable) Alumina TCP Stainless Steel (316L) Titanium Potential Applications • • • • • • Implants Drug delivery Cell growth Catalyst support Filtration Electrodes