Micromodels for Foam in Porous Media

advertisement

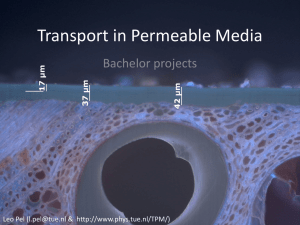

The use of PDMS micromodels to study CO2 foam transport in porous media Kun Ma, George J. Hirasaki, Sibani Lisa Biswal Department of Chemical & Biomolecular Engineering Rice University, Houston, TX 04/26/2011 Reservoir conditions for multi-phase flow Structure Wettability water-wet(0-80°) 8% strongly oil-wet (160180°) 15% intermediate wettability (80-100°) 12% oil-wet (100-160°) 65% Pores1 and vugs2 in reservoir rock 1. Image Source: U.S. Department of Energy 2. Image Source: www.slb.com/Schlumberger Wettability of carbonate reservoir rocks (water contact angle,161 samples1) 3. Chilingar, G. V.; Yen, T. F., Energy Sources 1983, 7, (1), 67-75. Microchannels in porous media Microfluidics in EOR process1 1. 2. Source: http://www.oil-gas-news.com Source: this study Bubble break-up in microchannels2 Goals of this work 1. To tune and pattern wettability in micromodels; 500 μm 2. To investigate foam flow in heterogeneous porous media. Microchannel and photolithography Photoresist Silicon wafer SU-8 photoresist mold PDMS Silicon wafer PDMS curing on SU-8 mold PDMS 1. Cubaud, T., U. Ulmanella, and C.M. Ho, Fluid Dynamics Research, 2006. 38(11): p. 772-786. PDMS after peeling it off the mold PDMS surface modification by UV-Ozone Ozone [1] 1. Berdichevsky Y, et al, Sensors and Actuators B-Chemical 2004, 97, (2-3), 402-408. Wettability control by water immersion Wettability maintenance by keeping UV-ozone-treated PDMS (1-hour curing at 80 °C) surface in contact with DI water. Schematic of the two-step process of wettability control An example of wettability patterning (a) Top view of the porous medium in Device A. (b) Top view of the porous medium in Device B. Left: initially saturated with dye solution; Right: after 2 min air injection at a volumetric flow rate of 1.0 ml/hr. The red scale bar at the upper left corner represents 500 μm. Design of a heterogeneous micromodel 2.57 cm Porous medium 1.19 cm Foam generator Foam generator surfactant 150 μm gas bubbles surfactant Heterogeneous porous media High permeable layer: grain radius 150 μm; pore throat 60 μm; porosity 0.45. Low permeable layer: grain radius 50 μm; pore throat 20 μm; porosity 0.45. 100% air injection to dye solution CO2 is only able to flow through the high permeability region leaving the aqueous solution trapped in the low permeability region Played at 1 frames per second, captured at 10 frames per second. Injected gas flow rate 5.0 ml/hr, injected liquid flow rate 0.0 ml/hr. 90% air injection to dye solution Adding surfactant to the foam allows the aqueous solution to be swept from both the high and low permeability regions Played at 1 frames per second, captured at 10 frames per second. Injected gas flow rate 4.5 ml/hr, injected liquid (0.2% wt coco betaine) flow rate 0.5 ml/hr. Image processing by MATLAB Only targeting the aqueous (green dye) solution Coworked with Dichuan Li, Rice University. Comparison of saturation profiles 1.1 sec (gas breakthrough) 2.7 sec (gas breakthrough) Conclusions ★ PDMS-based microfluidic devices provide a facile way to study the effect of wettability and heterogeneity on multi-phase flow in porous media; ★ A simple method has been demonstrated to tune and pattern the wettability of polydimethylsiloxane (PDMS) to generate microfluidic mimics of heterogeneous porous media; ★ Preliminary results in micromodels show that pre-generated foam is able to greatly improve sweep in low permeable region in a heterogeneous porous medium. Future work Understand the mechanism of foam propagation in heterogeneous porous media: - permeability dependence - cross flow - effect of surfactants - effect of foam quality - shear thinning effect