Operation of the electric arc furnace – With examples

advertisement

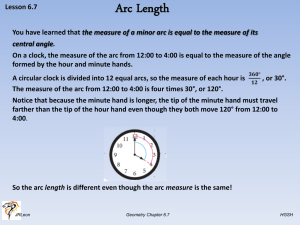

OPERATION OF THE ELECTRIC ARC FURNACE – WITH EXAMPLES Author: Luis Ricardo Jaccard jaccard@uol.com.br Introduction • Certain issues related to the operation of electric arc furnaces are well known but others, especially those relating to the effects of electrical parameters on consumption (energy and electrodes) or on the arc characteristics (stability and length) are frequently cause of misunderstandings. • The confusion usually arises from the propaganda of some regulators manufacturers that assign to their equipment the ability to increase power, reduce energy consumption, modify lengths and/or stabilize the arcs, as if this were not unique consequence of voltage, current and circuit reactance chosen by those responsible for the operation. 2 Electrical parameters and energy consumption Without doubt, choose the right operating parameters (voltage, current and reactance) is essential for obtaining the required active power and expected productivity with stable arc (appropriate power factor) and with the least possible consumption of electrodes, without excessive erosion of walls and roof of the furnace, avoiding overloading the transformer or disturbing excessively the electrical grid. But, except in extreme cases, the electrical parameters of operation have little or no influence on the amount of energy needed to produce a given amount of steel. 3 Energy consumption Energy consumption for producing one ton of steel depends on the size of the furnace, the type of charge, melting and shut down times and thermal losses in the environment, in the water cooled walls, in the slag and in the hot heel. Also depends on the temperature of tapped steel, on metal yield, and, among other factors, on the electrical losses in the conductors. Typical energy balance for a 100-ton furnace which operates with scrap loaded with two baskets: Energy in steel: 380 kWh/t Input: 565 kWh/t Energy in slag : 55 kWh/t Energy in electrical losses: 20 kWh/t Energy in gases and panels: 110 kWh/t Output: 565 kWh/t 4 Consumption of electrical and chemical energy In modern furnaces, power is supplied not only by electricity but also by the chemistry (oxygen reacting with carbon). In the previous example, the furnace demanded an amount of energy of 565 kWh per ton of product, but that energy could be supplied with different rates of electricity and chemistry, for example: Total energy Chemical energy Electrical energy 565 105 460 565 145 420 565 185 380 This is the same furnace consuming the same amount of energy but with different percentages of chemical energy. The electrical energy depends on the amount of chemical energy. 5 Electrical losses The electrical losses (I ². r) are those that occur in the conductors of the furnace according to the current flow. Let's see the effect of these losses on the energy consumption for an furnace that has a loss resistance of 0,4 mOhm, usually operates with 1200 V, 60 kA and power factor 0,75. We start from the premise that, for the normal type of charge of the furnace, the power consumption is 565 kWh/t, with 165 kWh/t for chemical energy. V (V) I (kA) P (MW) Electrical losses power (MW) Electric. losses c. (kWh/t) Energy consump. (kWh/t) Chemical energy. (kWh/t) Electrical energy (kWh/t) 1200 60 93,5 4,3 18,4 565,0 165 400,0 1200 50 77,9 3,0 15,6 562,2 165 397,2 700 60 54,5 4,3 31,6 578,2 165 413,2 It is observed that by reducing current from 60 kA to 50 kA occurs a very small reduction in energy consumption accompanied by a strong reduction of active power (lower productivity). Reducing the voltage from 1200 V to 700 V obviously causes a sharp drop in power with some increase in total energy consumption. 6 Analysis of energy consumption • The energy consumption of a furnace depends strongly on the type of load. • When the scrap has low density or the furnace has low volume is sometimes necessary to load the furnace with three or four baskets per heat. For loads made with more than two baskets, each additional load, increases energy consumption by about 25 kWh/t (for a 50 ton furnace). For our original example, if the load were conducted in four stages, the total energy consumption (electric + chemical) could be increased to 615 kWh/t (a bit less for a 100-ton furnace). • Energy consumptions usually are referred to the tons of product and, if the metal yield is low, specific consumption increases. If the furnace consumed 565 kWh per ton of product with yield of 89%, scrap with a lower density that causes a yield of 83% would increase the energy consumption to 606kWh/t. • Also consider the effect that a dirty scrap causes in energy lost in the slag, by requiring greater amounts of lime used. • Higher final steel temperature is also an obvious cause of higher energy consumption • High tap to tap times, especially when resulting from high power off times, are generally the main cause of high consumption. 7 Active Power • While the values of voltage, current and reactance do not cause a decisive effect on the energy consumption of the furnace, they are essential to achieving the desired productivity with a stable arc, low consumption of electrodes and normal arc attack to the walls. • To achieve a certain production of steel per hour, it will be required a certain power: P (kW) = Cee (kWh/t) x G (t) / Power On (h), where Cee is the specific consumption of electrical energy, G (t) is the weight of product per heat and Power On is the operating time per heat. • For a given process, as seen, the furnace requires a certain total amount of energy that can be provided with greater or lesser proportion of chemical energy. The furnace Power On time will always be proportional to the specific consumption of electricity but will decrease when increasing the consumption of chemical energy (see example). 8 Power ON time • Example: Power On times for a 100 tons furnace with total power consumption of 565 kWh / t, using different chemical energy consumption values and different active power values. Total Chemical Electrical energy energy energy (kWh/t) (kWh/t) (kWh/t) Power ON time for 80 MW (minutes) Power ON time for 85 MW (minutes) Power ON time for 90 MW (minutes) 565 125 440 33,0 31,0 29,3 565 145 420 31,5 29,6 28,0 565 165 400 30,0 28,2 26,6 565 185 380 28,5 26,8 25,3 565 205 360 27,0 25,4 24,0 9 Arc voltage and arc lenght • The arc voltage Va is equal to V x cos fi / 1.732, where V is the phase to phase voltage and cos fi is the operational cosine fi at the infinite bus. Be a furnace that operates with 75 MW active power and operational power factor of 0,75, powered by a 100 MVA transformer with taps of 1300 V, 1100 V and 900 V: Power (MW) Applied voltage (V) Current (kA) Arc voltage (V) 75 1300 44,4 563 75 1100 52,5 476 75 900 64,1 390 • For these three alternatives productivity will be almost equal. The main difference is that with higher voltages are needed lower currents (lower consumption of electrodes) and, also, higher arc lengths (more heat radiation to the walls). Arc length is proportional to arc voltage (usually 1 mm/V) 10 Reactance of the circuit To keep the true power factor of 0,75 for the three alternatives of the previous example certainly had to be modified the value of the reactance of the circuit for each case. From the equivalent circuit of the furnace can be deduced that the sine of the angle is directly proportional to the product of current and reactance and inversely proportional to the applied voltage: sine = I. X. 1.73 / V. For a power factor of 0,75, the sine must be equal to 0.66. The actual values (considering the effect of harmonics) of the reactance for the example would be: Power (MW) Applied voltage (V) Current (kA) Operational reactance (mOhm) 75 1300 44,4 11,2 75 1100 52,5 8,0 75 900 64,1 5,3 For a given power factor, increasing the voltage must be increased the reactance. 11 Reactance and arc stability Operational reactance Xop is greater than the sine wave reactance X due to the effect of harmonics. “Xop / X” factor increases as the cosine phi. As the current decreases, the cosine phi increases and the arc voltage (Va V . cos fi) also increases. But beyond a certain value, a further decrease in current causes a very strong increase of the reactance of the circuit, causing a decline in operational cos phi and also in arc voltage. This point is known as stability limit. For the regulator be able to maintain a certain current value is necessary that a decrease in current causes an increase in arc voltage and, therefore, for currents below the limit of stability the regulator fails to maintain expected current value. 12 Stable and unstable arc For 1000 V and reactance of 6 mOhm 550 When a decrease in current causes a decrease in arc voltage (rather than an increase, as would be normal), the regulator fails to maintain constant current, the electrodes go up and down without stopping. Electrode 500 Arc voltage (V) 450 400 350 UNSTABLE ARC STABLE ARC 300 250 200 kA 150 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 Stable and unstable arc Explanation of the previous graphic: To reduce the current is necessary to increase the arc length, raising the electrodes. Under normal conditions, the decrease in current causes a decrease in voltage drop and, consequently, the arc voltage increases. We have then a stable condition, because the arc length was increased by the regulator and the arc voltage also increased as the effect of the circuit. But when it is made an attempt to regulate a current lower than the corresponding to the stability limit, the distance between the electrodes and the load is greater than necessary to maintain the arc with the available voltage and extinction occurs. Due to the interruption of the current, the regulator lower the electrodes to cause re-ignition. But the resulting current will be higher than expected and the regulator raises the electrodes until a new arc extinction occurs. Thus, the electrode will remain up and down without stopping. This phenomenon is known as "pumping." In this case there is an incompatibility between the selected voltage and current, that in addition to greatly reduction of the active power, can cause vibrations in the arms and jerking of electrodes and water cooled cables. 14 Long arc and unstable arc It is quite common to associate an unstable arc with a long arc. But, in reality, an arc can be very long and perfectly stable. The arc length is defined by the arc voltage but stability is defined by the sinusoidal cosine phi which can not exceed a certain value (approximately 0,85 for the period of boring, 0,88 for melting and 0,90 for refining). The values of the following table were calculated for the boring-down period and for a sinusoidal reactance of 6 mOhm: V I (kA) Cos fi sinus. Cos fi real Va Arc stability 1200 65 0,826 0,670 464 Stable 1200 60 0,854 0,686 475 +/- Stable 1200 55 0,879 0,695 481 Unstable 1200 50 0,901 0,699 484 Much unstable 1200 45 0,921 0,698 483 Much unstable 15 Long arc and short arc • Clearly define if an arc is long or short is a relative matter. From a practical point of view one could say that for a modern high-capacity furnace, an arc of 250 mm is a short arc, an arc of 450 mm is long and one of 650 mm is much long. In fact, as was seen, it is possible to stabilize any length and constraints to further increase the length of the arc are: the erosion of the walls and foamy slag height. • However, in relation to this topic there are also some misunderstanding. Some manufacturers place on their electrode current controllers an option to "short arc" or “long arc" which in reality corresponds to “higher current" or “lower current". In fact, as can be seen in the previous table, a decrease in current causes a very small increase in the arc voltage and below a certain point (stability limit) destabilizes the arc. In addition, the power drops vertiginously. 16 Electrode consumption Electrode consumption (kg / t), for the same electricity consumption (kWh / t) is proportional to the ratio between the current and arc voltage I / Va (tip consumption) and a slightly more complex relationship corresponding to consumption by oxidation but that basically shows a dependence on (H x D / I ²), where H x D is the oxidation of the electrode surface (H is the height of oxidation and D is the diameter of the electrode). Based on the formula we conclude that the use of electrodes is inversely proportional to the arc voltage, as long as the diameter of the electrode adapts to the current (with decreasing current, lower electrode diameter). Not always a reduction in current causes a decrease in electrode consumption because when the current is too low in relation to the diameter of the electrodes a current reduction causes an increase in consumption by oxidation higher than the reduction of the tip consumption. This effect is heightened even more when the current falls below the stability limit (see figure). 17 Electrode consumption 18 Electrode consumption Electrode consumption (kg/t), for 700 V yand1100 V, reactance 4 mOhm, electrodes 600 mm, electrical energy consumption 415 kWh/t 5.2 4.9 4.7 4.4 Low impedance furnace 4.2 3.9 3.7 kg/t 3.4 3.2 2.9 700 V 2.7 43 MW 2.4 1100 V 2.2 1.9 95 MW 1.7 1.4 1.2 0.9 20 25 30 35 40 45 50 55 60 65 70 75 80 Corriente (kA) 19 Flicker and harmonic distortion Briefly, without going deeply into this important issue, we can say that the levels of flicker and harmonic distortion are proportional to the short- circuit power of the furnace Scf (reactive power when the electrodes are in direct contact with metal). From an operational perspective what can be done to decrease by approximately 20% the levels of disturbance (flicker and harmonics), without reducing the active power is to operate with low real power factor (about 0,63/0,65) because with this condition the relation Scf / P is lower, and, also, because the arc is more stable (see figure). 20 Flicker “Actual short circuit power/maximum short circuit power”, for the same active power, vs. real power factor 1.05 1.00 0.95 0.90 Lowest flicker 0.85 0.80 0.75 0.36 0.39 0.42 0.45 0.48 0.51 0.54 0.57 0.60 0.63 0.66 0.69 0.72 0.75 0.78 0.81 Real power factor 21 Summary • For maximum productivity (t/h) is required to operate at maximum value of active power that is compatible with the dimensions of the furnace and with the characteristics of the transformer and power circuit. • The active power is the product "arc voltage x current“. For a given active power, the higher the arc voltage, the greater the aggression of the arc to the walls and, in general, the lower electrode consumption. • The Power ON time is proportional to the specific consumption of electrical energy and inversely proportional to the active power. • A greater proportion of chemical energy reduces electrical energy consumption and indirectly reduces the Power ON time. 22 Summary • Large furnaces operated under normal conditions like, low downtime, scrap charge density sufficient to allow a few number of charges and high metal yield (0,89/0,90), also clean charge that reduces the amount of slag and pouring temperature of 1620/1640 ° C usually require an amount of specific energy of about 545 to 565 kWh per tonne of product (billets) or 485 to 508 kWh per tonne of metal charge. • A portion of the energy supplied is of chemical origin. The specific consumption of electricity depends on the amount of chemical energy provided. If a particular furnace operates with power consumption of 565 kWh/t and are supplied 165 kWh/t of chemical energy, electrical energy consumption will be 565-165 = 400 kWh/t. It is common in steel plants to establish goals to reduce just electrical consumption, when in fact, the aim should be to seek the minimum total energy consumption (electrical + chemical). 23 Summary • To get the regulator to maintain a certain current with stable arc, the circuit must have a reactance value that depends on the voltage and current used (sine phi sinusoidal = I . X. 1.73 / V must be sufficiently high for the cosine phi does not exceed certain value, e.g. 0,85 for the period of boring down). • The arc stability has no direct relation to the length of the arc, which depends only on the arc voltage. An arc can be very long and stable, provided it has an appropriate balance of voltage, current, and reactance. • Sometimes it is implied that a long arc depends on low current operation. In fact, the decrease in current causes a very small increase in arc voltage but from a certain point causes arc instability. 24 Summary • To operate with a certain active power (MW) and lower levels of disturbance of the electrical network (flicker and harmonics) is convenient to operate with low real power factor (0,60 to 0,65) but this requires a transformer with larger apparent power (MVA). • Operating electrical parameters (voltage, current, power, reactance, voltage arc) generally do not have great influence on the energy consumption. The exceptions are extreme cases, as the operation below the limit of stability (current or reactance to low for the applied voltage) or the operation with too low voltages and too high currents (high electrical losses). 25