AME436-S13-lecture7

advertisement

AME 436

Energy and Propulsion

Lecture 7

Unsteady-flow (reciprocating) engines 2:

Using P-V and T-s diagrams

Outline

Air cycles

What are they?

Why use P-V and T-s diagrams?

Using P-V and T-s diagrams for air cycles

Seeing heat, work and KE

Constant P and V processes

Inferring efficiencies

Compression & expansion component efficiencies

Correspondence between processes on P-V and T-s

Hints & tricks

AME 436 - Spring 2013 - Lecture 7 - Using P-V & T-s diagrams

2

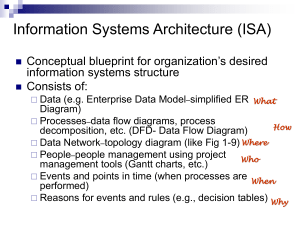

Air-cycles - what are they?

In this course we will work primarily with “air cycles” in which

the working fluid is treated as just air (or some other ideal gas)

In air cycles, changes in gas properties (CP, Mi, , etc.) due to

changes in composition, temperature, etc. are neglected; this

greatly simplifies the analysis and leads to simple analytic

expressions for efficiency, power, etc.

Later we’ll examine “fuel-air cycles” (using GASEQ) where the

“real” gases are considered and the properties change as

composition, temperature, etc. change (but still can’t account

for slow burn, heat loss, etc. since it’s still a thermodynamic

analysis that tells us nothing about reaction rates, burning

velocities, etc.)

In addition to the analytical results, P-V and T-s diagrams will be

used extensively to provide a visual representation of cycles

AME 436 - Spring 2013 - Lecture 7 - Using P-V & T-s diagrams

3

Why use P-V diagrams?

Pressure vs. time and cylinder volume vs. time are easily

measured in reciprocating-piston engines

∫ PdV = work

∫ PdV over whole cycle = net work transfer + net change in KE +

net change in PE = net heat transfer

Heat addition is usually modeled as constant pressure or constant

volume, so show as straight lines on P-V diagram

Note that V on P-V diagram is cylinder volume (m3) which is NOT a

property of the gas, whereas specific volume (v) (m3/kg) IS a

property of the gas (we need to use V since cycle work = ∫ PdV;

can’t use v since mass changes during intake/blowdown/exhaust)

AME 436 - Spring 2013 - Lecture 7 - Using P-V & T-s diagrams

4

Why use T-s diagrams?

Idealized compression & expansion processes are constant S

since dS ≥ Q/T; for adiabatic process Q = 0, for reversible =

(not >) sign applies, thus dS = 0 (note that dS = 0 still allows for

any amount of work transfer to occur in or out of the system,

which is what compression & expansion processes are for)

For reversible process, ∫TdS = Q, thus area under T-s curves

show amount of heat transferred

∫ TdS over whole cycle = net heat transfer = net work transfer +

net change in KE + net change in PE

T-s diagrams show the consequences of non-ideal compression

or expansion (dS > 0)

For ideal gases, T ~ heat xfer or work xfer or KE (see next 2

slides)

Efficiency can be determined by breaking any cycle into Carnotcycle “strips,” each strip (i) having th,i = 1 - TL,i/TH,i

AME 436 - Spring 2013 - Lecture 7 - Using P-V & T-s diagrams

5

T-s & P-v for control mass: work, heat & KE

For an ideal gas with constant CP & Cv:

h = CpT, u = CvT

and the 1st Law says, for a control mass with PE = 0 (in internal

combustion engines we can almost always neglect PE)

dE = d(U + KE) = d[m(u + KE)] = q - w

(note the use of “KE” rather than “u2/2” to avoid confusion

between u {internal energy} and u {velocity})

q = Q/m (heat transfer per unit mass)

w = W/m (work transfer per unit mass)

If no work transfer (dw = 0) or KE change (dKE = 0), du = CvdT = dq

q12 = Cv(T2 - T1)

If no heat transfer (dq = 0) or KE, du = CvdT = dw

w12 = -Cv(T2 - T1)

If no work or heat transfer

KE = KE2 – KE1 = -Cv(T2 - T1)

For a control mass containing an ideal gas with constant Cv,

T ~ heat transfer - work transfer - KE

Note that the 2nd law was not invoked, thus the above statements

are true for any process, reversible or irreversible

AME 436 - Spring 2013 - Lecture 7 - Using P-V & T-s diagrams

6

T-s & P-v for control volume: work, heat & KE

1st Law says, for a control volume, steady flow, with PE = 0

0 = Q -W + méë(hin - hout ) + ( KEin - KEout )ùû

For an ideal gas with constant CP, dh = CPdT h2 - h1 = CP(T2 - T1)

If 2 = outlet, 1 = inlet, and noting

h2 - h1 = q1®2 - w1®2 - ( KE2 - KE1 )

If no work transfer (dw = 0) or KE change (dKE = 0), du = CvdT = dq

q12 = CP(T2 - T1)

If no heat transfer (dq = 0) or KE, du = CvdT = dw

w12 = -CP(T2 - T1)

If no work or heat transfer

KE = KE2 – KE1 = -CP(T2 - T1)

For a control volume containing an ideal gas with constant CP,

T ~ heat transfer - work transfer - KE

(Same statement as control mass with CP replacing Cv)

Again true for any process, reversible or irreversible

AME 436 - Spring 2013 - Lecture 7 - Using P-V & T-s diagrams

7

T-s & P-v diagrams: work, heat & KE

3

w34 + (KE4 – KE3) = -Cv(T4-T3) (control mass)

w34 + (KE4 – KE3) = -CP(T4-T3) (control vol.)

q23 = Cv(T3-T2) (const. V)

q23 = CP(T3-T2) (const. P)

4

2

1

w12 + (KE2 – KE1) = -Cv(T2-T1) (control mass)

w12 + (KE2 – KE1) = -CP(T2-T1) (control vol.)

Case shown: cons. vol. heat in, rc = re = 3, = 1.4, Tcomb = fQR/Cv = 628K, P1 = 0.5 atm

AME 436 - Spring 2013 - Lecture 7 - Using P-V & T-s diagrams

8

T-s & P-v diagrams: work, heat, KE & PE

How do I know that work shown on the P-v (via ∫PdV) diagram is

the same as that shown (via CvT) on the T-s diagram? As an

example, for isentropic compression

AME 436 - Spring 2013 - Lecture 7 - Using P-V & T-s diagrams

9

T-s & P-v diagrams: work, heat, KE & PE

Going back to the 1st Law again

dE = dQ - dW Þ

ò dE = ò dQ - ò dW

Around a closed path, since E = U + KE + PE; since U is a property of the

system, ò dU = 0 , thus around a closed path, i.e. a complete thermodynamic

cycle (neglecting PE again)

But wait - does this mean that the thermal efficiency

No, the definition of thermal efficiency is

For a reversible process, Q = TdS, thus q = Tds and

Thus, for a reversible process, the area inside a cycle on a T-s diagram is

equal to (net work transfer + net KE) and the net heat transfer

AME 436 - Spring 2013 - Lecture 7 - Using P-V & T-s diagrams

10

T-s & P-v diagrams: work, heat & KE

Animation: using T-s diagram to determine heat & work

Heat

Heat transfer

transfer in

out

AME 436 - Spring 2013 - Lecture 7 - Using P-V & T-s diagrams

11

Constant P and V curves

Recall for ideal gas with constant specific heats (1st lecture)

æ T2 ö

æ V2 ö

æ T2 ö

æ P2 ö

S2 - S1 = CP lnç ÷ - Rlnç ÷ S2 - S1 = CV lnç ÷ + Rlnç ÷

è T1 ø

è V1 ø

è T1 ø

è P1 ø

If P = constant, ln(P2/P1) = 0 T2 = T1exp[(S2-S1)/CP]

If V = constant, ln(V2/V1) = 0 T2 = T1exp[(S2-S1)/Cv]

constant P or V curves are growing exponentials on a T-s

diagram

Since constant P or V curves are exponentials, as s increases, the

T between two constant-P or constant-V curves increases; as

shown later, this ensures that compression work is less than

expansion work for ideal Otto or Brayton cycles

Since CP = Cv + R, CP > Cv or 1/CP < 1/Cv, constant v curves rise

faster than constant P curves on a T-s diagram

Constant P or constant V lines cannot cross (unless they

correspond to cycles with different CP or CV)

AME 436 - Spring 2013 - Lecture 7 - Using P-V & T-s diagrams

12

Constant P and V curves

3

T(s) = T2exp[(s-s2)/Cv] (const vol.)

T(s) = T2exp[(s-s2)/CP] (const press.)

4

2

Constant v or P curves spread out as

s increases T3 - T4 > T2 - T1

1

T(s) = T1exp[(s-s1)/Cv] (const vol.)

T(s) = T1exp[(s-s1)/CP] (const press.)

AME 436 - Spring 2013 - Lecture 7 - Using P-V & T-s diagrams

13

Constant P and V curves

“Payback” for compression work and KE decrease

3

(T3 - T4) - (T2 - T1) ~ net work + KE increase

4

2

1

T2 - T1 ~ Work input + KE decrease during compression

Net work + KE decrease ~ (T3 - T4) - (T2 - T1)

= (T2 - T1)[exp(s/Cv) - 1] > 0 or (T2 - T1)[exp(s/CP) - 1] > 0

AME 436 - Spring 2013 - Lecture 7 - Using P-V & T-s diagrams

14

T-s diagram

Constant P and V curves

1200

Constant-v heat addition &

rejection (Otto cycle)

Temperature (K)

1000

800

600

400

200

Double-click chart to

open Excel spreadsheet

0

-100

0

100

200

300

Constant-P heat addition &

rejection (Brayton cycle)

400

500

600

700

800

Entropy (J/kg-K)

Constant-v curves are steeper than constant-P curves on the T-s

Both cases: T2/T1 = 1.552, = 1.4, fQR = 4.5 x 105 J/kg, P1 = 0.5 atm

The two cycles shown also have the same thermal efficiency (th)

AME 436 - Spring 2013 - Lecture 7 - Using P-V & T-s diagrams

15

Inferring efficienciesT-s diagram

1200

Temperature (K)

1000

Constant-v heat addition &

rejection (Otto cycle)

800

TH,i

600

400

200

0

-100

Carnot cycle “strip”

th,i = 1 - TL,i/TH,i

TL,i

Double-click chart to

open Excel spreadsheet

0

100

200

300

400

500

600

700

Entropy (J/kg-K)

Carnot cycles appear as rectangles on the T-s diagram; any cycle

can be broken into a large number of tall skinny Carnot cycle

“strips,” each strip (i) having th,i = 1 - TL,i/TH,i

AME 436 - Spring 2013 - Lecture 7 - Using P-V & T-s diagrams

16

Compression & expansion efficiency

If irreversible compression or expansion, dS > Q/T; if still adiabatic

(Q = 0) then dS > 0

Causes more work input (more T) during compression, less work

output (less T) during expansion

Define compression efficiency comp & expansion efficiency exp

hcomp º

Reversible adiabatic work input for given V or P ratio

Actual work input required for same V or P ratio

-CV [T1 (V1 /V2 )g -1 - T1 ] (V1 /V2 )g -1 -1

=

=

-CV (T2 - T1 )

T2 /T1 -1

(control mass, specified volume ratio)

hexp º

Actual work output for given V or P ratio

Reversible adiabatic work output for same V or P ratio

-CV (T2 - T1 )

T2 /T1 -1

=

=

g -1

-CV [T1 (V1 /V2 ) - T1] (V1 /V2 )g -1 -1

(control mass, specified volume ratio)

AME 436 - Spring 2013 - Lecture 7 - Using P-V & T-s diagrams

17

Compression & expansion efficiency

-CV [T1 (P2 /P1 )(g -1) / g - T1 ] (P2 /P1 )(g -1)/ g -1

hcomp =

=

-CV (T2 - T1)

T2 /T1 -1

(control mass, specified pressure ratio)

-CV (T2 - T1)

T2 /T1 -1

hexp =

=

-CV [T1(P2 /P1)(g -1)/ g - T1 ] (P2 /P1 )(g -1) / g -1

(control mass, specified pressure ratio)

Control volume: replace Cv with CP, but it cancels out so definitions

are same

These relations give us a means to quantify the efficiency of an

engine component (e.g. compressor, turbine, …) or process

(compression, expansion) as opposed to the whole cycle

AME 436 - Spring 2013 - Lecture 7 - Using P-V & T-s diagrams

18

Compression & expansion efficiency

Animation: comparison of ideal Otto cycle with non-ideal

compression & expansion

Same parameters as before but with comp = exp =0.9

1200

Temperature (K)

1000

800

600

400

2 charts on top of each other;

double-click each to open Excel

spreadsheets

200

0

-200

0

200

400

600

800

Entropy (J/kg-K)

AME 436 - Spring 2013 - Lecture 7 - Using P-V & T-s diagrams

19

4.5

4.5

4.0

4.0

Temperature (T/To)

Pressure (P/Po)

Correspondence between P-V & T-s

3.5

3.0

2.5

2.0

1.5

1.0

0.5

3.5

3.0

Pressure increasing

2.5

2.0

1.5

1.0

0.5

0.0

0.0

0

1

2

3

4

5

0

1

2

3

4

5

6

Entropy ((s-so)/R)

4.5

4.5

4.0

4.0

Temperature (T/To)

Pressure (P/Po)

Volume (V/Vo)

3.5

3.0

2.5

2.0

1.5

1.0

3.5

3.0

2.5

Volume increasing

2.0

1.5

1.0

0.5

0.5

0.0

0.0

0

1

2

3

Volume (V/Vo)

4

5

0

1

2

3

4

Entropy ((s-so)/R)

AME 436 - Spring 2013 - Lecture 7 - Using P-V & T-s diagrams

5

6

20

4.5

4.5

4.0

4.0

Temperature (T/To)

Pressure (P/Po)

Correspondence between P-V & T-s

3.5

3.0

Temperature increasing

2.5

2.0

1.5

1.0

3.5

3.0

2.5

1.5

1.0

0.5

0.5

0.0

0.0

0

1

2

3

4

Constant temperature

2.0

0

5

1

3

4

5

6

Entropy ((s-so)/R)

Volume (V/Vo)

2.5

3.5

2.0

Temperature (T/To)

Pressure (P/Po)

2

1.5

Entropy increasing

1.0

0.5

3.0

2.5

2.0

1.5

1.0

0.5

0.0

0

1

2

3

Volume (V/Vo)

4

5

Constant entropy

0.0

0

1

2

3

4

5

Entropy ((s-so)/R)

AME 436 - Spring 2013 - Lecture 7 - Using P-V & T-s diagrams

6

21

Example

Why do internal combustion engines compress before burning? Is it

possible to produce work or thrust without compression?

To generate positive area (thus net work) on a T-s diagram (left), the pre-heataddition process must be more nearly vertical than the heat addition process,

otherwise there is no area thus no work (middle). The best way to do this is with

isentropic compression followed by heat addition (left) - but it’s not required. You

could have (for example) constant-V heat addition followed by isentropic

expansion back to ambient P (right) and work would be generated without a

“real” compressor (although with lower efficiency.)

T

T

T

No area,

no work!

Net work

V

S

P

S

S

AME 436 - Spring 2013 - Lecture 7 - Using P-V & T-s diagrams

S

22

Example

Why is it necessary to add heat to generate work or thrust?

Without heat transfer, dq = 0 and thus (for reversible cycles) TdS = 0, thus

T dS = P dV = Net work = 0 (left figure). If the process is irreversible,

TdS < 0, thus T dS < 0 and thus = P dV = Net work < 0 (right figure).

ò

ò

ò

ò

T

T

Negative

work

No area,

no work!

S

S

AME 436 - Spring 2013 - Lecture 7 - Using P-V & T-s diagrams

23

Example

Consider the “Lenoir cycle” engine shown on the P-V diagram

a) Sketch the T-s diagram corresponding to the P-V diagram

2

1 2 const. V, increasing P

heat addition, s increases

2

P

T

2 3 const. s, decreasing P

expansion, T decreases

V

3

P

1

3 1 const. P, decreasing v

heat rejection, s decreases

1

3

V

s

b) Sketch modified P-V and T-s diagrams if the initial temperature is

increased by 10% (same P1, V1 and P2)

2’

2

2

P

T

P

P - V plot unchanged (but higher

T means less mass processed)

3’

V

P

1

3

V

1 P 1’

3

Higher T, same P s1, s2

increases

Still need 3 1 const. P

s

AME 436 - Spring 2013 - Lecture 7 - Using P-V & T-s diagrams

24

Example

c) Sketch modified P-V and T-s diagrams if the “compression ratio” V3/V1 is

increased by 20% (same P1, V1)

2’

1 2 const. V, P2 larger than

base cycle

2’

2

2

P

T

V

3’

3

P

1, 1’

Still need 3 1 const. P

1,1’

3 3’

V

On P-V, curves of const. T

slope less steeply than const. s,

thus T3’ > T3

s

d) Sketch modified P-V and T-s diagrams if a gas with higher is used

(same P1, V1, P2, R)

PV curves steeper if increases

2’

2, 2’

P

2

V

T

3’ 3

P

1,1’

1, 1’

3’

V

CV = R/(-1); if R = const. and

increases, CV decreases, thus

const.-v curves on T – s are

steeper

T2 doesn’t change since V1 = V2,

P1, P2 and R don’t change

3

s

AME 436 - Spring 2013 - Lecture 7 - Using P-V & T-s diagrams

25

Using T-s and P-v diagrams - summary

Thermodynamic cycles as they occur in IC engines are often approximated

as a series of processes occurring in an ideal gas

T-s and P-v diagrams are very useful for inferring how changes in a cycle

affect efficiency, power, peak P & T, etc.

The T (on T-s diagrams) and areas (both T-s & P-v) are very useful for

inferring heat & work transfers

Each process (curve or straight line) on T-s or P-v diagram has of 3 parts

An initial state

A process (const. P, v, T, s, as shown in the previous slides), constant area

(Rayleigh, Fanno or shock flow, discussed in propulsion section), etc.

A final state, which is usually

» For compression and expansion processes in reciprocating piston engines, a

specified volume relative to the initial state (i.e. a particular compression or

expansion ratio)

» For compressors in propulsion cycles, a specified pressure ratio

» For turbines in propulsion cycles, a specified temperature that makes the work

output from the turbine equal the work required to drive compressor and/or fan

» For diffusers in propulsion cycles, a specified Mach number (usually zero)

» For nozzles in propulsion cycles, the pressure after expansion (usually the

ambient pressure)

» For heat addition processes, either a specified heat input = ∫ Tds (i.e. a mixture

having a specified FAR and QR) thus a given area on the T-s diagram, or a

specified temperature (i.e. for temperature limited turbines in propulsion

cycles)

» The constant P and constant v exponential curves on the T-s diagram are very

useful for determining end states

26

AME 436 - Spring 2013 - Lecture 7 - Using P-V & T-s diagrams

Using T-s and P-V diagrams - summary

Three or more processes combine to make a complete cycle

When drawing P-V or T-s diagrams, ask yourself

What is the P, V, T and s of the initial state? Is it different from the

baseline case?

For each subsequent process

» What is the process? Is it the same as the baseline cycle, or does it change

from (for example) reversible to irreversible compression or expansion?

Does it change from (for example) constant pressure heat addition to heat

addition with pressure losses?

» When the process is over? Is the target a specified pressure, volume,

temperature, heat input, work output, etc.?

» Is a new process (afterburner, extra turbine work for fan, etc.) being added or

is existing one being removed?

» In gas turbine cycles, be sure to make work output of turbines = work input

to compressors and fans in gas

Be sure to close the cycle by having (for reciprocating piston

cycles) the final volume = initial volume or (for propulsion cycles)

(usually) the final pressure = ambient pressure

AME 436 - Spring 2013 - Lecture 7 - Using P-V & T-s diagrams

27