Lecture 17: Control Volumes: Applications 2

advertisement

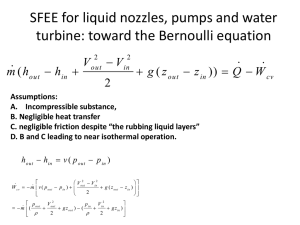

EGR 334 Thermodynamics Chapter 4: Section 9-10 Lecture 17: Control Volume Applications: Day 2 Quiz Today? Today’s main concepts: • Be able to set up mass and energy balance models for Turbines Pumps Compressors Boilers Heat Exchangers Nozzles Diffusers Throttle Reading Assignment: • Read Chapter 4, Sections 11-12 Homework Assignment: Problems from Chap 4: 75, 83, 87, 90 3 Modeling applications with Control Volumes: Many important applications involve one inlet, one exit control volumes at steady state. Other systems include feature additional inlet and outlet streams. One very common device, the heat exchanger, requires multiple streams of mass flow to be modeled. Mass Rate Balance: multi-path, steady state dm C V 0 m i m e mi dt me Energy Rate Balance: 1 path, steady state 1 2 2 0 Q cv W cv m ( hi h e ) (V i V e ) g ( z i z e ) 2 W Q dECV m i ei dt m e ee 4 Control Volume Applications: Nozzles Compressor Diffuser Boiler Turbine Pump Throttling Valve Heat Exchanger Heat Exchangers ►Direct contact: A mixing chamber in which hot and cold streams are mixed directly. ►Tube-within-a-tube counterflow: A gas or liquid stream is separated from another gas or liquid by a wall through which energy is conducted. Heat transfer occurs from the hot stream to the cold stream as the streams flow in opposite directions. Sec 4.9: Heat Exchangers 6 Direct Contact Heat Exchangers: In direct contact heaters, mass streams combine and exchange heat by mass transport as well as by convection and conduction. m Examples: H ot _ in m C old _ in m exit Swamp Coolers Hot-Cold water faucet Cooling Towers Sec 4.9: Heat Exchangers 7 Separate Flow (Tube) Heat Exchangers: Heat transfer occurs by conduction through a material that separates individual flow streams Parallel Flow: Streams enter and leave along same directions Cross Flow: Stream pass along direction perpendicular to each other Counter Flow: Streams enter and leave opposite each other. 8 Tube Heat Exchanger are all around you. Still Radiator Home air conditioning Industrial Heating Boiler Geothermal Heating Refrigerator condenser Industrial Systems Power Plant Sec 4.9: Heat Exchangers A heat exchanger attempts to maximize the heat transfer between separate fluid streams. Designed to maximize “contact” between the two fluids Maximize time of contact and Maximize area of contact 9 Sec 4.9: Heat Exchangers 10 For Separate Stream Heat Exchangers: Mass Balance Model: m F luid 1 _ in m F luid 1 _ exit and m F luid 2 _ in m F luid 2 _ exit Energy Balance Model: dE C V dt QCV WCV 2 2 Vi Ve m i hi gz i m e he gz e 2 2 Steady Insulated No work State from surroundings V0 Horizontal Section (or very short vertical) 0 m f 1_ i h f 1_ i h f 1_ e m f 2 _ i h f 2 _ i h f 2 _ e First Fluid Second Fluid Sec 4.9: Heat Exchangers 11 Example: (4.81) A feedwater heater operates at steady state with liquid water entering at inlet #1 at 7 bar, 42 °C and a mass flow rate of 70 kg/s. A separate stream of water enters at inlet 2 as a two phase liquid-vapor mixture at 7 bar with a quality of 98%. Saturated liquid at 7 bar exits the feedwater heater at #3. Ignoring heat transfer with surroundings and neglecting KE and PE effects, determine the mass flow rate in kg/s at inlet #2. state 1 m (kg/s) 70 x 2 3 0.98 0 p (bar) 7 7 7 T (°C) 42 165 165 175.9 2722.17 697.22 h (kJ/kg) Look up h values on Table A-2 and A-3 #2 7 bar 98% #1 7 bar 42 °C 70 kg/s #3 7 bar Sat. Liq. Assumptions •Steady State •KE= PE = 0 •QCV= 0 Sec 4.9: Heat Exchangers 12 Example: (4.81) Determine the mass flow rate in kg/s at inlet #2. state 1 m (kg/s) 70 2 x 3 0.98 0 p (bar) 7 7 7 T (°C) 42 165 165 175.9 2722.17 697.22 h (kJ/kg) Mass Balance: h3 h f ( a t 7 b a r ) 6 9 7 .2 2 kJ kg h2 h f x ( h g h f ) 697.22 kJ kg 2722.17 h1 h f 0.98[2763.5 697.22] kJ kg kJ kg a t T1 1 7 5 .9 kJkg Energy Balance: m 1 m 2 m 3 Combining From Table A-3 In Out 0 m 1 h 1 m 2 h 2 m 3 h 3 0 m 1 h 1 m 2 h 2 m 1 m 2 h 3 h 1h 3 175.9 697.22 m 2 m1 18.0 kg / s 70 kg / s 697.22 2722.2 h 3h 2 Sec 4.9: Heat Exchangers 13 Example: (4.85) A parallel flow heat exchanger has separate streams of air and water. Streams undergo no significant change of pressure. Ignore heat loss to the surroundings and changes in KE and PE. Apply ideal gas to the air stream. If both streams leave at the same temperature, determine the exit temperature. state state 11 22 33 H H22O O 44 Air Air m m (kg/s) (kg/s) 10 10 10 10 55 55 pp (bar) (bar) 11 11 11 11 TT 99.63 oC hh (kJ/kg) (kJ/kg) 1200 1200 KK 2675.5 from Table A-3 at psat = 1 bar, T1= Tsat = 99.63 C and h1=hg=2675.5 kJ/kg Using energy balance: for the heat exchanger dE C V dt QCV WCV 2 2 Vi Ve m i hi gz i m e he gz e 2 2 Reducing this with assumptions 0 m H 2 O ( h1 h 2 ) m a ir ( h3 h 4 ) Sec 4.9: Heat Exchangers 14 Example: (4.85) A parallel flow heat exchanger has separate streams of air and water. Streams have no significant change of pressure. Ignore heat loss to the surroundings and changes in KE and PE. Apply ideal gas to the air stream. If both stream leave at the same temperature, determine the exit temperature. state 1 2 3 H 2O 4 Air m (kg/s) 10 10 5 5 p (bar) 1 1 1 1 T 99.63oC h (kJ/kg) 2675.5 1200 K Using ideal gas model 0 m H 2 O ( h1 h 2 ( Texit , 1 b a r )) m a ir c p (T3 T exit ) Note: since h2 depends upon T2=T4 and p2 = 1 bar, it could be found from Table A-4 if the exit temperature were known. This problem can be solved by picking a value of T2 and then looking up h2 and checking to see if it satisfies the equation. It can also be easily solved using IT’s iterative solver. Sec 4.9: Heat Exchangers 15 Solution using IT Exit Temperature T2 T4 5 6 1 K 2 8 8 C o Then the heat transfer between the two fluids is Q a ir H 2 O m H 2 O ( h 2 h1 ) (1 0 kg / s )(3 0 4 9 2 6 7 5) kJ / kg 3 7 4 0 kJ / s state 1 2 3 H 2O 4 Air m (kg/s) 10 10 5 5 p (bar) 1 1 1 1 T 99.63oC 288 1200 K 288 h (kJ/kg) 2675.5 3049 Throttling Devices ►Throttling Device: a device that achieves a significant reduction in pressure by introducing a restriction into a line through which a gas or liquid flows. Means to introduce the restriction include a partially opened valve or a porous plug. Sec 4.10: Throttling Devices 17 Throttling Device: Reduces Pressure Mass Balance: m in m i exit m in m exit m i Typical Energy Balance simplifications, dE CV dt Steady State Q CV W CV 2 2 vi ve m i hi gz i m e h e gz e 2 2 No heat No work transfer v0 hi h e Horizontal Section (or very short vertical) Sec 4.10: Throttling Devices 18 Example: (4.92) Refrigerant 134a enters the expansion valve of an air conditioning unit at 140 psi, 80 °F and exits at 50 psi. If the refrigerant undergoes a throttling process, what are the temperature, in °F, and the quality at the exit valve? state inlet x Assumptions • Steady State • KE= PE = 0 • QCV= WCV = 0 exit ? P (psi) 140 50 T (°F) 80 ? h (BTU/lb) 37.27 Enthalpy of saturated liquid at 80°F 140 psi 80 °F 50 psi Sec 4.10: Throttling Devices 19 Example: (4.92) Refrigerant 134a state inlet x exit ? P (psi) T (°F) h (BTU/lb) 140 80 50 40.27 At 140 psi, the saturation T is 100.56 °F, so this is a super-cooled liquid. There are no tables for super-cooled liquid, so neglect pressure effects. h1 h f ( T at 80 F ) 37.27 o 37.27 h 2 h1 = 3 7 .2 7 From Table A-10E h2 h f x ( h g h f ) x he h f hg h f x BTU lb BTU lb 37.27 24 . 14 83 . 29 0 . 158 20 end of Lecture 17 Slides