GasTurb 12: How to Calculate a Single Cycle

advertisement

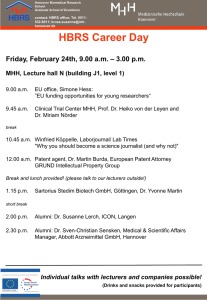

GasTurb 12 – Tutorial 1 Copyright © GasTurb GmbH HOW TO CALCULATE A SINGLE CYCLE A Jet Engine Example The Program offers three Scopes that differ For professional in the amount of detail performance work use the being simulated. The Engine Design option. Choose Basic Performance Thermodynamics or… scope is least demanding for the user. More… if youtextbook want to Only simple determine the engine wisdom is considered. geometry. Copyright © GasTurb GmbH Let us begin with a jet engine simulation. Select the most simple engine architecture, a Turbojet. A click on Performance in the Engine Design button group begins the calculation Copyright © GasTurb GmbH We Need Some Data… Cycle Design Input Data Window Copyright © GasTurb GmbH All input is in clear nomenclature - no cryptic abbreviations are used. Switching to Imperial Units is easy Let’s go back to SI Units Thermodynamic Station Input Copyright © GasTurb GmbH Click here to start the calculation The flow areas at the stations are either a design point input or are derived from a Mach number. These flow areas affect only the static pressures and temperatures. The main cycle parameters like thermal efficiency or thrust, for example are not affected by the input on the Stations page. Copyright © GasTurb GmbH Single Cycle Output Most people are using m for mass flow. When the standard nomenclature was agreed on the letter M could not be used because in early FORTRAN programs any property name beginning with M was an Integer. The letter W for mass flow reminds of the outdated designation weight flow. On this summary page there is no room for lengthy property names. The international standard nomenclature for performance computer programs is employed. For example, P is total pressure, T total temperature and W is employed for mass flow. Explanations are at your fingertip: Click a symbol – for example TSFC - and you get a detailed explanation. Thermodynamic Station Output Copyright © GasTurb GmbH Here are all the details at the thermodynamic stations. The flow areas at all the stations are stored in memory. During off-design simulations the static pressures and temperatures are calculated from flow area, mass flow, total pressures and total temperature. Getting Additional Output I need to know a cycle property which is not listed on the output page. Copyright © GasTurb GmbH Open the Composed Values window – a powerful formula editor. Composed Values Editor Click here to check and evaluate all composed values. Compose your additional output values from the input and output quantities. You can even use empirical correlations (Tables) and more than 50 predefined Functions Copyright © GasTurb GmbH Example: Calculate the kinetic energy of the nozzle exhaust JetEnergy=W8*V8^2/2 Dividing by 1000 yields the Jet Energy in kW Copyright © GasTurb GmbH Output with Composed Value After closing the Composed Values window run the case again – now you have JetEnergy as additional output. Next let us have a look at the EnthalpyEntropy diagram of the cycle Enthalpy-Entropy Diagram The diagram shows real numbers. See how it changes with compressor pressure ratio Copyright © GasTurb GmbH Click here to open the slider definition window. We now freeze this diagram for making comparisons with another cycle. Click to reduce to one slider only Using the Slider… Copyright © GasTurb GmbH Move the Slider to the right – this increases Pressure Ratio. Now you see how the pressure ratio of the compressor affects the hot section part of the cycle Copyright © GasTurb GmbH Single Cycle Output This is again the original cycle. The turbine pressure ratio of 3.178 is easily achievable with a single stage turbine. In fact, a single stage turbine can work up to a pressure ratio of 4 with an acceptable efficiency. Let us search for the compressor pressure ratio which yields exactly the turbine pressure ratio of 4. Close this window to proceed. Copyright © GasTurb GmbH Single Cycle Input Data Page We will vary (iterate) compressor Pressure Ratio in such a way that Turbine Pressure Ratio is equal to 4. We open now the Iterations input window. Iteration Variable Input Min and max boundaries for the variable are required for numerical reasons. The min and max values need not to be accurate, they are for excluding physical meaningless numbers (like very low pressure ratios) from the calculations. Copyright © GasTurb GmbH From all the input Variables we choose Pressure Ratio and drag it from the selection tree to the table. Iteration Target Input Copyright © GasTurb GmbH From all the output quantities we choose Turbine Pressure Ratio as Target and drag it from the selection tree to the table. Iteration Target Value Input Enter the target value here… Copyright © GasTurb GmbH …and activate the iteration. Then close the window. Single Cycle Input Data Page Copyright © GasTurb GmbH Now we are ready to run the case Copyright © GasTurb GmbH The Cycle with Turbine Pressure Ratio = 4 This slide ends the Single Cycle Tutorial