GasTurb 12: Off-Design Simulation Tutorial

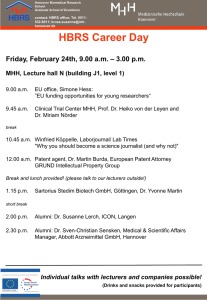

advertisement

GasTurb 12 – Tutorial 3 Copyright © GasTurb GmbH INTRODUCTION TO OFF DESIGN SIMULATIONS Off-Design Simulations Let us begin with a jet engine. Select the most simple engine architecture, a Turbojet. Copyright © GasTurb GmbH Select as Scope Performance and then click Off Design A click on Standard Maps begins the off-design calculation. Copyright © GasTurb GmbH We Need Some Data… Off-Design Input Data Page After reading the file, the cycle design point is calculated. This happens in the background. The standard compressor and turbine maps are scaled in such a way that theyNow fit to cyclethe cycle wethe calculate design point as an design point. Copyright © GasTurb GmbH off-design point Copyright © GasTurb GmbH Off-Design Point Summary The contents of this summary page is identical to that of the cycle design point Operating Point Details Copyright © GasTurb GmbH This is the Standard High Pressure Compressor Map file On this page those details of the operating point are presented that are not needed for a cycle design calculation. This is the Standard High Pressure Turbine Map file Compressor Map The circle marks the cycle design point, the yellow square marks the off-design operating point. Copyright © GasTurb GmbH In this special case – because we have calculated the cycle design point in off-design mode – the yellow square is inside the circle. Turbine Map The circle marks the cycle design point, the yellow square marks the off-design operating point. Copyright © GasTurb GmbH There are six different versions of a turbine map. The y-axis can be Pressure Ratio or Corrected Work. Here Turbine Pressure Ratio is shown over the product of Corrected Flow and Corrected Speed. Turbine Map Copyright © GasTurb GmbH Here Turbine Pressure Ratio is shown over Corrected Speed. The corrected flow is shown as contour lines in % of the maximum corrected flow in the map Copyright © GasTurb GmbH Turbine Map Here Turbine Pressure Ratio is shown with the same axes as a compressor map: Turbine Pressure Ratio over Corrected Mass Flow. The disadvantage of this format is that all the speed lines nearly collapse. Copyright © GasTurb GmbH Thermodynamic Stations Here you get all the details at the thermodynamic stations. The engine geometry - all the flow areas at all stations - is among the results of the cycle design point calculation. Off-Design Input Data Copyright © GasTurb GmbH Here you can choose whether Relative Spool Speed ZXN or Burner Exit Temperature ZT4 is given. Enter 2 to make Burner Exit Temperature an input and use 1200 for it Let us run a case with 1200 K Burner Exit Temperature. Off-Design Result Copyright © GasTurb GmbH The solution is found by iteration Compressor Map Cycle design point Copyright © GasTurb GmbH Compressor operating point for T4=1200K Off-Design Iteration Copyright © GasTurb GmbH Iteration targets are flow These are the estimated values ofbetween continuity These are the variables theofiteration variables.components If the iteration and power the iteration. Betavalues fails are to converge, you can try with balances auxiliary coordinates in better estimates for the variables. component maps. Now let us calculate the complete sea level static operating line. Off-Design Input Operating Line Copyright © GasTurb GmbH Reset to 1 and enter for the HPC Spool Speed ZXN also 1 Operating Line Input Increase the Number of Points to 20, The line commences with the then run theoperating case by clicking the single point which was calculated Operating Line button before the operating line window was opened. A series of points with decreasing gas generator spool speed will be calculated. The default step size of relative spool speed is 0.025. Copyright © GasTurb GmbH Answer No Compressor Operating Line We will employ a handling bleed to cure that problem. Copyright © GasTurb GmbH Here the compressor surges Off-Design Input Operating Line Re-run the operating line Click Controls to show the controls button group. Then click the Bleed button Copyright © GasTurb GmbH Enter numbers in all 3 boxes Repeat the Operating Line Calc Copyright © GasTurb GmbH Answer this time Yes Switch Automatic Bleed “On” Copyright © GasTurb GmbH Enter 1 for the second operating line, then click Run Compressor Operating Lines With and Without Bleed Copyright © GasTurb GmbH Let us have other views on the data With bleed the surge problem does not exist. The Default Plot Copyright © GasTurb GmbH With bleed the surge problem does not exist. However, with bleed the fuel consumption is higher… Copyright © GasTurb GmbH New Picture Copyright © GasTurb GmbH New Picture T4 = f(Corrected Spool Speed) Copyright © GasTurb GmbH With bleed the surge problem does not exist; however, the burner exit temperature is significantly higher This slide ends the Introduction to Off-Design Simulations Tutorial