Process - U

advertisement

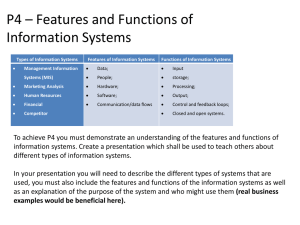

PROCESS SELECTION AND FACILITY LAYOUT Chapter 6 MIS 373: Basic Operations Management LEARNING OBJECTIVES • After this lecture, students will be able to 1. Compare the four basic processing types 2. Describe product layouts and their main advantages and disadvantages 3. Describe process layouts and their main advantages and disadvantages 4. Develop simple product layouts 5. Develop simple process layouts MIS 373: Basic Operations Management 2 PROCESS SELECTION • Process selection • Deciding on the way production of goods or services will be organized • Occurs when: • Planning of new products or services • Technological changes in product or equipment • Competitive pressure MIS 373: Basic Operations Management 3 PROCESS SELECTION AND SYSTEM DESIGN Forecasting (demand) Capacity Planning Layout Product and Service Design Technological Change MIS 373: Basic Operations Management Facilities and Equipment Process Selection Work Design 4 PROCESS STRATEGY • Key aspects of process strategy: • Capital Intensity • The mix of equipment and labor that will be used by the organization • Process flexibility • The degree to which the system can be adjusted to changes in processing requirements due to such factors as • Product and service design changes • Volume changes • Changes in technology MIS 373: Basic Operations Management 5 NEW PROCESS STRATEGY HBR 12/6/12 Three Examples of New Process Strategy There are three fundamental ways that companies can improve their processes in the coming decade: 1. expand the scope of work managed by a company to include customers, suppliers, and partners; • Shift to global, virtual, cross-organizational teams of specialized entities that are knitted together to serve customers • To keep such a multiparty system from degenerating into chaos, virtual process teams must have aligned goals and support systems. 2. target the increasing amount of knowledge work; and • Big data analytics • Crowdsourcing, e.g., innocentive.com, TopCoder.com & Heritage Health Prize • HBR : Using the Crowd as an Innovation Partner 3. reduce cycle times to durations previously considered impossible • Agile processes • Managers must speed the flow of information so that decisions can be made faster at all levels, from top to bottom. PROCESS SELECTION Process choice is demand driven: 1. Variety: How much? 2. Equipment flexibility: To what degree? 3. Volume: Expected output? • Process Types MIS 373: Basic Operations Management 7 PROCESS SELECTION Process choice is demand driven: 1. Variety • How much? 2. 3. Equipment flexibility • To what degree? Volume • Expected output? Process Types • Job shop • Small scale • e.g., doctor, tailor • Batch • Moderate volume • e.g., bakery • Repetitive/assembly line • High volumes of standardized goods or services • e.g., automobiles • Continuous • Very high volumes of nondiscrete goods • e.g., petroleum products MIS 373: Basic Operations Management 8 TYPES OF PROCESSING Repetitive/ Assembly Job Shop Batch Description Customized goods or services Semistandardized goods or services Standardized goods or services Highly standardized goods or services Advantages Able to handle a wide variety of work Flexibility; easy to add or change products or services Low unit cost, high volume, efficient Very efficient, very high volume Moderate cost per unit, moderate scheduling complexity Low flexibility, high cost of downtime Very rigid, lack of variety, costly to change, very high cost of downtime Disadvantages Slow, high cost per unit, complex planning and scheduling MIS 373: Basic Operations Management Continuous 9 PRODUCT-PROCESS MATRIX Flexibility/Variety Opportunity costs Volume Out of pocket costs • The diagonal represents the “ideal” match • Hybrid process are possible (e.g., job-shop & batch) • Process choice may change as products goes through its life-cycles MIS 373: Basic Operations Management 10 PROCESS CHOICE EFFECTS Activity/ Function Projects Batch Repetitive Continuous Cost estimation Simple to complex Difficult Somewhat routine Routine Routine Cost per unit Moderate Low Low Very high Job Shop High Equipment used Varied General purpose General purpose Special purpose Special purpose Fixed costs Varied Low Moderate High Very high Variable costs High High Moderate Low Very low Labor skills Low to high High Moderate Low Low to high Marketing Promote capabilities Promote capabilities Promote Promote Promote capabilities; semistandardized standardized standardized goods and goods and goods and services services services Scheduling Complex, subject Complex to change Moderately complex Routine Routine Project: used for work that is none routine with a unique set of objective to be accomplished in a limited time frame, e.g., launching a new product, publishing a book MIS 373: Basic Operations Management 11 PRODUCT AND SERVICE PROFILING Product or service profiling Linking key product or service requirements to process capabilities Key dimensions relate to o Range of products or services that can be processed o Expected order sizes o Expected frequency of schedule changes MIS 373: Basic Operations Management 12 DISCUSSION Work with a partner and match the following products or services with the best process Products/Services Processes Ice-cream manufacturer Automatic carwash Job-shop Batch Steel Repetitive Books Continuous Airlines Surgery Movie theater Sugar Beer Flour Tips: Think in terms of those key dimensions: o o o Range of products or services that can be processed Expected order sizes Expected frequency of schedule changes TECHNOLOGY • Technological Innovation • The discovery and development of new or improved products, services, or processes for producing or providing them • Technology • The application of scientific discoveries to the development and improvement of products and services and/or the processes that produce or provide them • Process technology includes methods, procedures, and equipment used to produce goods and provide services. • RFID, online banking, 3D printing, … MIS 373: Basic Operations Management 14 FACILITIES LAYOUT • Layout • The configuration of departments, work centers, and equipment, with particular emphasis on movement of work (customers or materials) through the system • Facilities layout decisions arise when: • Designing new facilities • Re-designing existing facilities • The basic objective of layout design is to facilitate a smooth flow of work, material, and information through the system. MIS 373: Basic Operations Management 15 BASIC LAYOUT TYPES • Product layout • Layout that uses standardized processing operations to achieve smooth, rapid, high-volume flow • Process layout • Layout that can handle varied processing requirements • Fixed position layout • Layout in which the product or project remains stationary, and workers, materials, and equipment are moved as needed • Combination layouts MIS 373: Basic Operations Management 16 PRODUCT LAYOUTS • Product layout • • Layout that uses standardized processing operations to achieve smooth, rapid, high-volume flow How? Raw materials or customer Material and/or labor Station 1 Material and/or labor Station 2 Material and/or labor Station 3 Station 4 Finished item Material and/or labor Used for Repetitive Processing Repetitive or Continuous MIS 373: Basic Operations Management 17 PRODUCT LAYOUTS • Although product layouts often follow a straight line, a straight line is not always the best, and layouts may take an L, O, S, or U shape. Why? • • • • L: Image source: mdcegypt.com O: S: U: more compact, increased communication facilitating team work, minimize the material handling MIS 373: Basic Operations Management 18 NON-REPETITIVE PROCESSING: PROCESS LAYOUTS • Process layouts • Layouts that can handle varied processing requirements Dept. A Dept. C Dept. E Dept. B Dept. D Dept. F Used for Intermittent processing Job Shop or Batch MIS 373: Basic Operations Management 19 PRODUCT LAYOUTS Advantages • High rate of output • Low unit cost • Labor specialization • Low material handling cost per unit • High utilization of labor and equipment • Established routing and scheduling • Routine accounting, purchasing, and inventory control MIS 373: Basic Operations Management Disadvantages Creates dull, repetitive jobs Poorly skilled workers may not maintain equipment or quality of output Fairly inflexible to changes in volume or product or process design Highly susceptible to shutdowns Preventive maintenance, capacity for quick repair and spare-parts inventories are necessary expenses Individual incentive plans are impractical 20 PROCESS LAYOUTS Advantages • Can handle a variety of processing requirements • Not particularly vulnerable to equipment failures • General-purpose equipment is often less costly and easier and less costly to maintain • It is possible to use individual incentive systems MIS 373: Basic Operations Management Disadvantages • In-process inventories can be high • Routing and scheduling pose continual challenges • Equipment utilization rates are low • Material handling is slow and less efficient • Complicates supervision • Special attention necessary for each product or customer • Accounting, inventory control, and purchasing are more complex 21 FIXED POSITION LAYOUTS • Fixed Position Layout • Layout in which the product or project remains stationary, and workers, materials, and equipment are moved as needed • E.g., farming, firefighting, road building, home building, remodeling and repair, and drilling for oil MIS 373: Basic Operations Management 22 COMBINATION LAYOUTS • Some operational environments use a combination of the three basic layout types: • Hospitals • Supermarket • Shipyards • Some organizations are moving away from process layouts in an effort to capture the benefits of product layouts MIS 373: Basic Operations Management 23 LINE BALANCING Line balancing The process of assigning tasks to workstations in such a way that the workstations have approximately equal time requirements Goal: Obtain task grouping that represent approximately equal time requirements since this minimizes idle time along the line and results in a high utilization of equipment and labor Why is line balancing important? 1. It allows us to use labor and equipment more efficiently. 2. To avoid fairness issues that arise when one workstation must work harder than another. • Input • Tasks sequencing (precedence diagram) • Tasks time • Operating time MIS 373: Basic Operations Management 24 PRECEDENCE DIAGRAM • Precedence diagram • A diagram that shows elemental tasks and their precedence requirements Task Duration Immediate (min) predecessor a Select material 0.1 - b Make petals 1.0 a c Select rhinestones 0.7 - d Glue rhinestones 0.5 b, c e Package 0.2 d MIS 373: Basic Operations Management 25 CYCLE TIME • Cycle time • The maximum time allowed at each workstation to complete its set of tasks on a unit • Minimum Cycle Time = longest task time = 1.0 min • Maximum Cycle time = Σt = sum of task time = 2.5 min MIS 373: Basic Operations Management 26 OUTPUT RATE OF A LINE • Cycle time also establishes the output rate of a line Operating time per day Cycle time = Desired output rate Operating time per day Output rate = Cycle time MIS 373: Basic Operations Management 27 HOW MANY WORKSTATIONS ARE NEEDED? • The required number of workstations is a function of: • Desired output rate • The ability to combine tasks into a workstation • (theoretical) Minimum number of stations Nmin= ∑t Cycle time where Nmin = theoretical minimum number of stations ∑ t = sum of task times MIS 373: Basic Operations Management 28 HOW MANY WORKSTATIONS ARE NEEDED? • The required number of workstations is a function of: • Desired output rate The ability to a combine tasks into a workstation Q:• Why this is theoretical value? A: There are often scraps or idle times. • (theoretical) Minimum number of stations Example: ∑ tto finish 4 tasks, each require 6 hours Nmin= A station can handle 8 hours of tasks a day. Cycle amount time You will need 4 stations to complete all tasks, instead of 3. where Nmin = (6+6+6+6) / 8 = 3 Nmin = theoretical minimum number of stations ∑ t = sum of task times MIS 373: Basic Operations Management 29 DESIGNING PRODUCT LAYOUTS Some Heuristic (Intuitive, may not result in optimal solution) Rules: Assign tasks in order of most following tasks Count the number of tasks that follow Assign tasks in order of greatest positional weight. Positional weight is the sum of each task’s time and the times of all following tasks. MIS 373: Basic Operations Management 30 EXAMPLE: ASSEMBLY LINE BALANCING • Arrange tasks (shown in the figure) into three workstations • Assume the cycle time of each workstation is 1.2 min. • Assign tasks in order of the most number of followers • Break tie using greatest positional weight MIS 373: Basic Operations Management 31 • Assign tasks in order of the most number of followers Time Workstation Remaining 1 1.2 Eligible Revised Assign Time Task Remaining Station Idle Time a, c 2 3 Start with CT (1.2 min. in this example) MIS 373: Basic Operations Management 32 • Assign tasks in order of the most number of followers Time Workstation Remaining 1 1.2 Eligible Revised Assign Time Task Remaining a, c a Station Idle Time 1.1 2 3 MIS 373: Basic Operations Management 33 Time Workstation Remaining 1 1.2 1.1 Eligible a, c c, b Revised Assign Time Task Remaining a Station Idle Time 1.1 2 3 MIS 373: Basic Operations Management 34 Time Workstation Remaining 1 1.2 1.1 Eligible Revised Assign Time Task Remaining a, c c, b a b Station Idle Time 1.1 0.1 2 3 Break tie using greatest positional weight MIS 373: Basic Operations Management 35 Time Workstation Remaining 1 1.2 1.1 0.1 Eligible a, c c, b c Revised Assign Time Task Remaining a b Station Idle Time 1.1 0.1 2 3 MIS 373: Basic Operations Management 36 Time Workstation Remaining 1 1.2 1.1 0.1 Eligible Revised Assign Time Task Remaining a, c c, b c a b - Station Idle Time 1.1 0.1 0.1 2 3 Can’t assign c to this workstation because the workstation doesn’t have enough time (0.1) to complete c (0.7). MIS 373: Basic Operations Management 37 Eligible Revised Assign Time Task Remaining 1.2 1.1 0.1 a, c c, b c a b - 1.1 0.1 1.2 c c 0.5 Time Workstation Remaining 1 2 Station Idle Time 0.1 3 Start with CT (1.2 min. in this example) MIS 373: Basic Operations Management 38 Eligible Revised Assign Time Task Remaining 1.2 1.1 0.1 a, c c, b c a b - 1.1 0.1 1.2 0.5 c d c d 0.5 0 Time Workstation Remaining 1 2 Station Idle Time 0.1 0 3 MIS 373: Basic Operations Management 39 Eligible Revised Assign Time Task Remaining 1.2 1.1 0.1 a, c c, b c a b - 1.1 0.1 1.2 0.5 c d c d 0.5 0 1.2 e e 1 Time Workstation Remaining 1 2 3 Station Idle Time 0.1 0.0 1.0 Start with CT (1.2 min. in this example) MIS 373: Basic Operations Management 40 Eligible Revised Assign Time Task Remaining 1.2 1.1 0.1 a, c c, b c a b - 1.1 0.1 1.2 0.5 c d c d 0.5 0 1.2 e e 1 Time Workstation Remaining 1 2 3 Station Idle Time 0.1 0.0 1.0 Idle time per cycle =0.1+0.0+1.0=1.1 MIS 373: Basic Operations Management 41 LAYOUT a&b c&d e (0.1+1.0) (0.7+0.5) (0.2) Task Duration Immediate (min) predecessor a Select material 0.1 - b Make petals 1.0 a c Select rhinestones 0.7 - d Glue rhinestones 0.5 b, c e Package 0.2 d MIS 373: Basic Operations Management 42 MEASURING EFFECTIVENESS • Balance delay (percentage of idle time) • Percentage of idle time of a line Balance Delay = Idle time per cycle Nactual × Cycle time × 100% where Nactual = actual number of stations • Efficiency • Percentage of busy time of a line Efficiency = 100% − Balance Delay MIS 373: Basic Operations Management 43 EXAMPLE: MEASURING EFFECTIVENESS Eligible Revised Assign Time Task Remaining 1.2 1.1 0.1 a, c c, b c a b - 1.1 0.1 1.2 0.5 c d c d 0.5 0 1.2 e e 1.0 Time Workstation Remaining 1 2 3 Station Idle Time 0.1 0.0 1.0 Percentage of idle time = [(0.1 + 0 + 1.0) ÷ (3 × 1.2)] × 100% = 30.55% Efficiency = 100% – 30.55% = 69.45% MIS 373: Basic Operations Management 44 EXERCISE PROBLEMS (Textbook page 267) Using the information contained in the table shown, do each of the following: 1. Draw a precedence diagram. 2. Assuming an eight-hour workday, compute the cycle time needed to obtain an output of 400 units per day. 3. Determine the minimum number of workstations required. 4. Assign tasks to workstations using this rule: Assign tasks according to greatest number of following tasks. In case of a tie, use the tiebreaker of assigning the task with the longest processing time first. 5. Compute the resulting percent idle time and efficiency of the system EXERCISE SOLUTION 1. Draw a precedence diagram EXERCISE SOLUTION 2. Assuming an eight-hour workday, compute the cycle time needed to obtain an output of 400 units per day Cycle time = Operating time per day Desired output rate = 480 minutes per day 400 units per day = 1.2 minutes per cycle EXERCISE SOLUTION 3. Determine the minimum number of workstations required ∑t 3.8 minutes per unit Nmin= = 1.2 minutes per cycle Cycle time time per station where = 3.17 stations ( round to 4) Nmin = theoretical minimum number of stations ∑ t = sum of task times EXERCISE SOLUTION 4. Assign tasks to workstations using this rule: Assign tasks according to greatest number of following tasks. In case of a tie, use the tiebreaker of assigning the task with the longest processing time first. EXERCISE SOLUTION 5. Compute the resulting percent idle time and efficiency of the system Percent idle time = Idle time per cycle Nactual × Cycle time = 1.0 min. 4 × 1.2 min. = 20.83% × 100% DESIGNING PROCESS LAYOUTS • The main issue in designing process layouts concerns the relative placement of the departments • Measuring effectiveness • key objectives in designing process layouts are to minimize: • transportation cost • distance • time MIS 373: Basic Operations Management 51 INFORMATION REQUIREMENTS • In designing process layouts, the following information is required: 1. A list of work stations (departments) to be arranged and their dimensions 2. A projection of future work flows between the pairs of work centers 3. The distance between locations - and the cost per unit of distance to move loads between them 4. The amount of money to be invested in the layout 5. A list of any special considerations 6. The location of key utilities, access and exit points, etc. MIS 373: Basic Operations Management 52 DESIGNING PROCESS LAYOUTS MINIMIZE TRANSPORTATION COSTS • Goal: • Assign departments 1, 2, 3 to locations A, B, C in a way that minimizes transportation costs. A B C • Heuristic: • Assign departments with the greatest interdepartmental work flow first to locations that are closet to each other. MIS 373: Basic Operations Management 53 EXAMPLE: MINIMIZE TRANSPORTATION COSTS Distance Location 40 Trip From\To A B C A-B 20 A - 20 40 B-C 30 - 30 A-C 40 B C Closest - Pair Work flow From\To 1 2 3 1-3 170 1 - 30 170 2-3 100 - 100 1-2 30 2 3 MIS 373: Basic Operations Management 20 B 30 C Place dept. 1&3 in A&B Work flow Department A Highest work flow 54 EXAMPLE: MINIMIZE TRANSPORTATION COSTS • Place departments 1&3 in A&B (2 options) 1 A 3 B 3 C A 1 B C • 2&3 have higher work flow than 1&2 (100>30) • 2&3 should be located closer than 1&2 • C closer to B than to A (30<40) • Solution: 30 1 A 170 3 B MIS 373: Basic Operations Management 100 40 A 20 Trip B 30 C Pair Work flow A-B 20 1-3 170 B-C 30 2-3 100 A-C 40 1-2 30 2 C 55 CLOSENESS RATINGS • Allows the considerations of multiple qualitative criteria • Input from management or subjective analysis • Indicates the relative importance of each combination of department pairs Muther’s grid MIS 373: Basic Operations Management 56 CLOSENESS RATINGS • Muther’s grid Dept. 1 Dept 2. Dept 3. Dept 4. Dept. 5 A A E X U U X O I A A O X A A Dept 6. MIS 373: Basic Operations Management A E I O U X Absolutely necessary Very important Important Ordinary importance Unimportant Undesirable Suppose this is the floor plan of your company, how would you arrange the six departments? 57 CLOSENESS RATINGS: EXAMPLE 1. List critical departments (either A or X): A X Dept. 1 1-2 1-4 Dept 2. 1-3 3-6 Dept 3. 2-6 3-4 3-5 Dept 4. 4-6 Dept. 5 5-6 Dept 6. MIS 373: Basic Operations Management A A E X U U X O I A A O X A A 58 CLOSENESS RATINGS: EXAMPLE 2. Form a cluster of A links (beginning with the department that appears most frequently) 4 2 A 1-2 Dept. 1 1-3 Dept 2. 2-6 3-5 4-6 6 5 5-6 A A E X U U X O I A A O X A A Dept 3. Dept 4. Dept. 5 Dept 6. 3. Take the remaining A links in order and add them to this cluster where possible (rearranging as necessary) Form separate clusters for departments that do not link with the main cluster. MIS 373: Basic Operations Management 4 2 1 6 5 3 6-59 CLOSENESS RATINGS: EXAMPLE 4. Graphically portray the X links 1 3 4 X 1-4 3-6 3-4 6 Dept. 1 A A E X U U X O I A A O X A A Dept 2. Dept 3. Dept 4. Dept. 5 5. Adjust A cluster as necessary. Dept 6. (in this case, the A cluster also satisfies the X cluster). 4 2 1 MIS 373: Basic Operations Management 6 5 3 60 CLOSENESS RATINGS: EXAMPLE 4 2 6 1 Dept. 1 5 1 3 4 3 6 6. Fit cluster into arrangement (e.g., 2x3) may require some trial and error. Departments are considered close not only when they touch side to side but also when they touch corner to corner. 1 2 6 3 5 4 Dept 2. Dept 3. Dept 4. Dept. 5 A A E X U U X O I A A O X A A Dept 6. 7. Check for possible improvements MIS 373: Basic Operations Management 61 KEY POINTS • Process choice is demand driven. • Process type and layout are a function of expected demand volume and the degree of customization that will be needed. • Each process type and layout type has advantages and limitations that should be clearly understood when making process selection and layout decisions. • Line balancing helps improving the efficiency of product layouts whereas Muther’s grid helps deciding process layouts MIS 373: Basic Operations Management 62