PTTx - IPN

advertisement

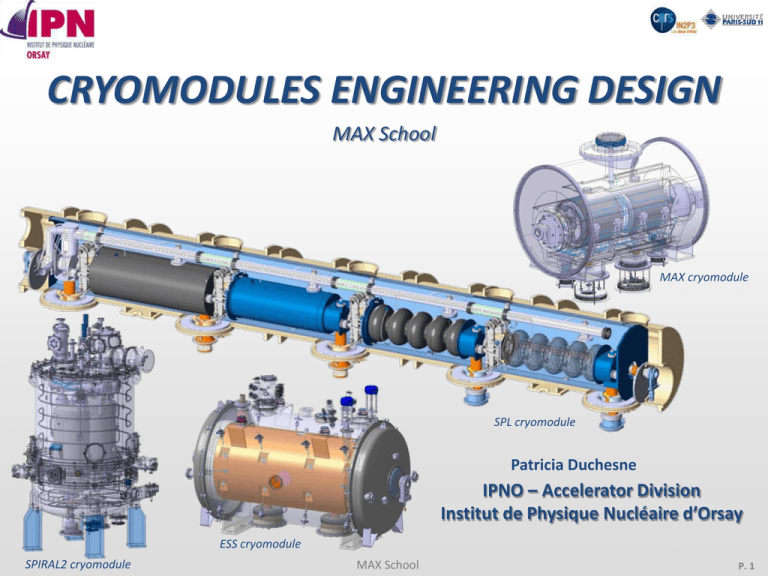

CRYOMODULES ENGINEERING DESIGN MAX School MAX cryomodule SPL cryomodule Patricia Duchesne IPNO – Accelerator Division Institut de Physique Nucléaire d’Orsay ESS cryomodule SPIRAL2 cryomodule MAX School P. 1 CONTENTS INTRODUCTION BASIC FUNCTIONS MAIN COMPONENTS CRYOGENIC SCHEME OF A CRYOMODULE THERMAL ASPECTS MECHANICAL ASPECTS DIFFERENT CONCEPTS OF SUPPORTING ASSEMBLY PROCESS CONCLUSION 2013/10/02 MAX School P. 2 CONTENTS INTRODUCTION BASIC FUNCTIONS MAIN COMPONENTS THERMAL ASPECTS MECHANICAL ASPECTS DIFFERENT CONCEPTS OF SUPPORTING ASSEMBLY PROCESS CRYOGENIC SCHEME OF A CRYOMODULE 2013/10/02 MAX School P. 3 DESIGN OF A CRYOMODULE A cryomodule is an unit cell of an accelerator that contains some Superconducting Radio Frequency (SRF) cavities and all the components required to their operation at cryogenic temperatures. INTRODUCTION Warm quadrupole Cryomodule (3 cavities =0.65 ) SPL Layout (2010): segmented architecture Cryomodule (8 cavities =1 ) SPL Cryomodule (8 cavities =1) 2013/10/02 MAX School P. 4 DESIGN OF A CRYOMODULE A cryomodule is: A part of an accelerating section A part of an overall cryogenic system INTRODUCTION Type of cavities, number of cavities, focusing elements: The accelerator design determines in part the composition of the cryomodule Independent cryogenic subsystems or connected to each other: The overall cryogenic system impacts on the segmentation of the accelerator and therefore on the cryomodule The design of a cryomodule depends on several parameters: The accelerator design (accelerating and guide components, sequence) The overall cryogenic system (independent subsystems or connected each other) The expected performance of the accelerator (reliability, availability ...) The cost Manufacturing cost: high filling factor (long cryomodule, short interconnections) Operating cost: static heat losses (long cryomodules cryogenically connected) 2013/10/02 MAX School P. 5 CRYOMODULES/CRYOSTATS, SEVERAL EXAMPLES GANIL-SPIRAL2 FRANCE ESS-LUND-SWEDEN INTRODUCTION Beginning in 2019 DESY- HAMBURG-GERMANY J-PARC-TOKAI-JAPAN SNS, TENNESSEE-USA LHC – CERN-SWITZERLAND CEBAF, J-LAB-VIRGINIA-USA 2013/10/02 MAX School P. 6 CONTENTS INTRODUCTION BASIC FUNCTIONS MAIN COMPONENTS THERMAL ASPECTS MECHANICAL ASPECTS DIFFERENT CONCEPTS OF SUPPORTING ASSEMBLY PROCESS CRYOGENIC SCHEME OF A CRYOMODULE 2013/10/02 MAX School P. 7 BASIC FUNCTIONS BASIC FUNCTIONS A cryogenic environment for the cold mass Cryogenic distribution (piping, phase separator, valves): He coolant (liquid or gas) at required temperatures o The vessels of the cavities/magnets are filled with liquid helium at 4K or lower temperature. o The active thermal shield can be cooled with helium gas o The magnetic shield o The power coupler Thermal insulation (shield, vacuum and superinsulation) against all sources of heat transfer from room temperature to cryogenic temperature o Heat conduction o Heat transfer by convection o Thermal radiation Supporting and positioning components o Structural support of the cold mass o Precise alignment of the cavities regarding the beam and reproducibility with thermal cycles Interface between the cold mass and the room temperature o Connection points for integrated systems: current, RF, instrumentation and cryogenics Magnetic protection against the magnetic field from the earth and other sources 2013/10/02 MAX School P. 8 CONTENTS INTRODUCTION BASIC FUNCTIONS MAIN COMPONENTS THERMAL ASPECTS MECHANICAL ASPECTS DIFFERENT CONCEPTS OF SUPPORTING ASSEMBLY PROCESS CRYOGENIC SCHEME OF A CRYOMODULE 2013/10/02 MAX School P. 9 MAIN COMPONENTS Vacuum vessel Thermal Insulation Interface Vacuum vessel Cryogenic piping String of cavities Supporting components MAIN COMPONENTS Supporting and positioning Thermal shields Thermal Insulation Cryogenic piping Cryogenic environment 1,80m Magnetic shield Magnetic protection Thermal shield Magnetic shield Supporting components ESS Spoke Cryomodule Cold mass (cavities, magnets) 2013/10/02 MAX School P. 10 COLD MASS (CAVITIES, MAGNETS) String of dressed superconducting RF cavities (equipped with their helium vessel and their ancillaries) and possibly presence of superconducting magnets of focalization SC Cavity: Pure niobium, Helium vessel: titanium, stainless steel Assembly string: ultra cleanliness required for the internal walls of the cavity and those of the MAIN COMPONENTS coupler The string is prepared in clean room with mounting of the power couplers, warm cold transitions and vacuum valves at the extremities Cavity: elliptical, spoke, quarter-wave, and half-wave resonators Warm cold transition Inter cavity bellows Helium vessel Vacuum valve Cold Tuning system Power coupler 2013/10/02 ESS String of spoke cavities MAX School P. 11 MAGNETIC SHIELD Providing a protection against the earth magnetic field and fields from other sources (ex: magnet stray fields) AMUMETAL (nickel-iron alloys) at room temperature, CRYOPERM at low temperatures MAIN COMPONENTS Around the cavity (shield at low temperature) To be efficient, the shield has to be cooled before the critical temperature of the cavity (superconductivity) Around all the components of the vacuum vessel (shield at room temperature) Magnetic shield with a cooling system between two walls (Cryoperm): magnetic shield (Cryoperm) around each cavity: SPL Short Test Cryomodule ESS Spoke Cryomodule 2013/10/02 MAX School P. 12 CRYOGENIC PIPING Pipes providing cryogenic fluids at different temperatures Stainless steel, aluminium or copper Cryogenic piping depends on the cryogenic distribution system of the accelerator (see § Cryogenic scheme of a cryomodule): MAIN COMPONENTS - Cryomodule cryogenically connected to form a cryo-string (minimizing the number of cryogenic feeds) Cooling and return pipes integrated into the cryomodule - Cryomodule cryogenically independent Each cryomodule is connected to the Cryogenic Transfer Line (CTL) via a valve box. Cryogenic piping provides cryogenic fluids to: - Thermal shield - Magnetic shield - Power coupler - Warm to cold transition - Cavity Cryogenic valves Biphasic tube Thermal shield tube Warm to cold transition pipe Magnetic shield tube 2013/10/02 MAX School Coupler tube P. 13 THERMAL SHIELDS Active thermal shield at intermediate temperature (50-80K) Passive thermal shield (Multi Layer Insulation) To minimize the radiation heat transfer Metallic shield: aluminium or copper actively cooled at 50K-80K Its design is strongly conditioned by the problematic of thermal contractions and of assembly MAIN COMPONENTS MLI (Multi Layer Insulation): composed of some reflective layers (aluminium) alternated of some insulating spacers (mylar) placed on: the surface of the thermal shield (~ 30 layers) the surface of the components at lower temperatures (~ 10 layers) Thermal shield MLI 2013/10/02 MAX School P. 14 SUPPORTING COMPONENTS Supports maintaining all the components in the vacuum vessel Resin, composite, Titanium alloy, ... Stiff and stable over the lifetime: Support the weight of the components and maintain the good alignment of the cold mass MAIN COMPONENTS Warm to cold transitions: limit conduction heat transfer Tie rods 2013/10/02 MAX School P. 15 VACUUM VESSEL Metallic vessel containing the insulating vacuum to minimize convection heat transfer Carbon steel, stainless steel, aluminium (pressure requirements, magnetic shield potential, the cost ...) A tight structure: guarantee 10-7 bar inside the vacuum level MAIN COMPONENTS A rigid structure: No risk of buckling It must provide: − − − − − Floor fixing supports Ports for coupler, cryogenic piping, instrumentation ... Attachment points of the cold mass Supports for alignment ... Instrumentation port Vacuum vessel Cover ends 2013/10/02 Attachment point of the cavity MAX School Safety valve coupler port Optical alignment Supports P. 16 VACUUM VESSEL Examples of vacuum vessel studied at IPNO: ESS Spoke Cryomodule: MAX Spoke Cryomodule: SPIRAL2 Cryomodule B: 1,3m 1,2m MAIN COMPONENTS 2,8m 1,9m 2,8m ESS Elliptical Cryomodule: 1,2m ~ 6,5m 1,16m SPL Short test Cryomodule: 0,8m 2013/10/02 ~ 7m MAX School P. 17 CONTENTS INTRODUCTION BASIC FUNCTIONS MAIN COMPONENTS CRYOGENIC SCHEME OF A CRYOMODULE THERMAL ASPECTS MECHANICAL ASPECTS DIFFERENT CONCEPTS OF SUPPORTING ASSEMBLY PROCESS 2013/10/02 MAX School P. 18 CRYOGENIC SCHEME OF A CRYOMODULE COOLING MODES SRF cavities are generally cooled with an isothermal saturated bath (equilibrium vapour and liquid phases): - T = 4.2K and P = 1 bar - T < 2.1K and P < 30 mbar Stable pressures, limitation of pressure fluctuations that have an impact on the cavity frequency A bath at T< 4.2K is generated by isenthalpic expansion, through JouleThomson valves (pumping) Accelerator magnets are often cooled with subcooled liquid: Surfaces completely covered with liquid, stabilization of superconductors 2013/10/02 Helium phase diagram Superfluid Pressurized Helium Helium I Saturated Helium I Pressurized Helium II Saturated Helium II MAX School P. 19 P&ID (Piping and Instrumentation Diagram) CRYOGENIC SCHEME OF A CRYOMODULE Example of P&ID of ESS spoke cryomodule: Cryogenic Transfer Line (CTL) Helium supply and return pipes 19.5 bar, 40K 3 bar, 4.5K 31 mbar Cold box Cryogenic distribution (valves) and Heat exchanger Cryomodule Cool down lines Filling lines Helium gas return lines helium gas line String of cavities at 2K • Safety elements (burst disk, pressure safety valves), • Control valves • Vacuum circuit • Process diagnostics, Sensors 2013/10/02 Saturated helium II bath at 2K in the phase separator pipe MAX School P. 20 CONTENTS INTRODUCTION BASIC FUNCTIONS MAIN COMPONENTS THERMAL ASPECTS MECHANICAL ASPECTS DIFFERENT CONCEPTS OF SUPPORTING ASSEMBLY PROCESS CRYOGENIC SCHEME OF A CRYOMODULE 2013/10/02 MAX School P. 21 PHYSICAL MECHANISMS OF HEAT LOSS Insulation vacuum 293K 40K - 80K RF cavities 2K-4K Convection heat transfer: - Negligible with a good insulating vacuum into the vessel (< 10-3mbar) Coupler THERMAL ASPECTS Radiation heat transfer: - The most important (varies in T4) Supports Conduction heat transfer Radiation heat transfer Conduction heat transfer: - Penetrations from room temperature (power coupler, instrumentation…) - Mechanical supports Identify all heat losses: Impact on the choices of materials and geometric shapes Total static heat load (in relation to the cryogenic fluid consumption). Dynamic heat load (operation of the cavity and power coupler): • Pulsed operation: Pstatic >> Pdynam get a good thermal insulation • Continuous wave operation (CW): Pdynam>>Pstatic focus on the problems of heating 2013/10/02 MAX School P. 22 HEAT CONDUCTION Transfer by heat conduction All mechanical supports Heat load (W) by conduction is given by the Fourier law: Q T A Q L λ( T).dT 0 THERMAL ASPECTS T 1 A L l(T) 300 K 4K T2 : section (m²) : length (m) : thermal conductivity (W/mK-1) L x Calculated from: Q constant AISI 304L To limit Q while guaranteeing mechanical strength: Q1 Q2 80 K 300 K 4K Geometry: A, L L2 Material with low conductivity l(T) L1 Thermal intercepts at intermediate temperatures: AISI 304L 2013/10/02 MAX School P. 23 HEAT CONDUCTION Example: Support rods between the helium vessel and the vacuum vessel Material: AISI 304L Diameter D: 8mm Length L: 665mm 4 A Without any thermal intercept: Q λ( T).dT 0.23W by rod L 300 L 300K THERMAL ASPECTS With a thermal intercept at T=80K: 80 4 A A λ( T).dT Q λ( T).dT Q 80 4 L x 300 x 80 The optimal position x can be defined by minimizing the power required to dissipate the heat taking into account Carnot efficiency with Ẇ: Required work for refrigerator to Tc Q Ideal Carnot cycle: dissipate Q at Tc (Tw=300K) Tw Tc W 220 296 ==> W W 80 W 4 Q80 Q4 80 4 a1 a x ==> W 2 Optimum: x/L = 0.65 x L 1 x L L Q 80 0.59W Q4 0.04W 2013/10/02 MAX School x 80K With a thermal intercept at 80K Without any thermal intercept 0 4K 0.65 Ẇ=17.2W against Ẇ=4.8W P. 24 HEAT CONDUCTION THERMAL ASPECTS Example: Support rods of SPIRAL2 CRYOMODULE B Lateral rods between the cavity and the vacuum vessel, thermalized at 80K 2013/10/02 Copper tresses between the rods and the thermal shield MAX School P. 25 HEAT CONDUCTION Example: Support posts of cryomodules type TTF (XFEL, ILC) Heat loads: A Q L T2 λ( T).dT Q 70 9.6W Q 4.5 0.84W Q 1.8 0.04W T1 THERMAL ASPECTS Estimation of the refrigerator load: Carnot efficiency W W W 93.3W W 70 4.5 1.8 Without thermal intercepts: 2.79W Q Aluminium disk connected to the thermal shield at 70K 300K L1=27mm 70K Tube G-11 thickness 2.2mm, ext=300mm L2=37mm L3=10mm 462.2W W 4,5K Aluminium disk connected to the thermal shield at 4,5K 1,8K 2013/10/02 MAX School P. 26 HEAT RADIATION Transfer by heat radiation All surfaces of the components Heat load (W) by radiation is given by the Stefan-Boltzmann law: THERMAL ASPECTS Q12 .F12.S1.(T14 T24 ) S1 F12 : Stefan Boltzmann constant (=5.67x10-8 W/m²K-4) : Surface area (m²) : View factor (depends on geometry and emissivity) Where Q12 is the thermal radiation power from surface 1 to surface 2. Q12 F12 Infinite coaxial cylinders: 1 S1 (simplified model of a thermal 1 S 2 shield with the vacuum vessel) 1 1 1 2 To limit Q12 : Material with low emissivity (shiny surfaces...) Active thermal shield at intermediate temperature Passive thermal shield MLI (MultiLayer superInsulation) 2013/10/02 MAX School P. 27 HEAT RADIATION Example: Heat load by radiation with or without thermal shields Vacuum vessel in stainless steel: Diameter = 0.8 m = 0.2 T° = 293K Cold mass (string of cavities): Diameter = 0.5 m = 0.1 T° = 2K THERMAL ASPECTS Without any shield: Q cold mass 53W Active aluminum thermal shield: Q thermalshield 68W Q 0.2W Diameter = 0.7 m = 0.1 T° = 75K cold mass MLI layers around active aluminium thermal shield: 30 MLI layers from 293K: 1.5W/m² Q thermalshield 3.3W Q 0.2W cold mass 2013/10/02 MAX School P. 28 HEAT RADIATION Example: Thermal shields of the Cryomodule B – SPIRAL2 THERMAL ASPECTS MLI placed on the magnetic shields of each cavity, piping and bellows MLI placed on the thermal shield Active thermal shield in copper 2013/10/02 MAX School P. 29 EVALUATION OF THE STATIC HEAT LOAD From the heat load budget cryogenic fluids consumption (dimensioning of the cryogenic plant) Example: Heat load budget of a cryomodule Static heat load at 4K: •Helium port Static heat load at 50K: Rod THERMAL ASPECTS •Thermal shield •Warm to cold transition 293K 50K Cavity Warm to cold transition Static heat load at 4K: Helium vessel 4K •Warm to cold transition Thermal shield •Power coupler •Supporting system Vacuum vessel Static heat load at 50K: •Supporting system 2013/10/02 MAX School P. 30 EXAMPLES OF THE STATIC HEAT LOAD ESS Spoke Cryomodule (in progress) Cryomodule B – SPIRAL2 Static loads at 80K [W] THERMAL ASPECTS Components Static loads at 4K [W] Thermal shield 46.7 0.42 Supporting system (rods) 3.93 2.55 Warm to cold transitions 1.67 1.54 Two power couplers 10 1.5 Two cold tuning system 1.07 0.16 Instrumentation 0.3 2.30 Total 64 8.5 Components Static loads at 50K [W] Static loads at 2K [W] Thermal shield 10 0.4 Supporting system (rods) 4 0.2 Warm to cold transitions 6 0.4 Safety equipement 4.1 0.25 Two power couplers - 2. Control valves 3 1.5 Instrumentation 8 0.2 Total 35 5. MAX Spoke Cryomodule (in progress) Components Static loads at 70K [W] Static loads at 10K [W] Static loads at 2K [W] Thermal shield <30 - 0.2 Space frame 16 1 <0.1 Warm to cold transitions 4.34 - 0.2 Safety equipement <2. - 0.1 Two power couplers <35 <7 <2.1 Instrumentation <5 Total <92 Cryomodule Type TTF Static loads at 40/80K [W] Total 2013/10/02 70 Static loads at 4K [W] 13 Static heat loads at 2K 3.5 MAX School 0.5 <8 <3.2 P. 31 CONTENTS INTRODUCTION BASIC FUNCTIONS MAIN COMPONENTS THERMAL ASPECTS MECHANICAL ASPECTS DIFFERENT CONCEPTS OF SUPPORTING ASSEMBLY PROCESS CRYOGENIC SCHEME OF A CRYOMODULE 2013/10/02 MAX School P. 32 MECHANICAL STRENGTH Gravity: 1g MECHANICAL ASPECTS Temperature field • Thermal contractions • Thermal stresses Patm Patm External pressure 50K 293K Cavities 2K or 4K Gravity • Weight of the components Vacuum Thermal shield Patm Vacuum vessel Patm Impact on the alignment and the stability of the components 2013/10/02 MAX School P. 33 TEMPERATURE FIELD Temperature field in an assembly Thermal contractions and stresses 2-4K MECHANICAL ASPECTS After the cool down, the temperature field in a cryomodule: 50-80K 300K String of cavities Thermal shield Some thermal contractions appear on all components: With different temperatures String of cavities at 2/4K: niobium, titanium, stainless steel... Thermal shields at 50/80K: copper, aluminium With different materials Cryogenic lines from 2K to 300K: stainless steel, aluminium... Supports from 2K to 300K Theses contractions can create some high thermal stresses. Solving problem of stresses will depend on the type of connection between the components according to their function: - Supporting, - Transferring cryo fluid - Vacuum circuit 2013/10/02 MAX School P. 34 THERMAL CONTRACTIONS AND STRESSES How to estimate the thermal contractions and stresses? Thermal contractions: T1 A rod: MECHANICAL ASPECTS DL = a . L . DT L a : Thermal expansion coefficient (1/K or 1/°C) L : Characteristic length (m) DT : Difference between final and initial temperatures (K or °C) T1 A tube: DL T2 Thermal expansions of different materials DL/L: R DR DR = a . R . DT T2 Thermal stresses: If a tensile force F is applied to extend the length to the initial length: According to the Hooke Law: F DL E E a D S L 2013/10/02 MAX School P. 35 THERMAL CONTRACTIONS AND STRESSES Limiting the thermal stresses according to the type of connections - For supporting, - For transferring cryo fluid - For the vacuum circuit F DL E E a D S L MECHANICAL ASPECTS Material with low expansion coefficient: a Ex: Resins, composites, TiA6V Bellows Material with low Young modulus: E Ex: Resins, composites Geometry: Flexibility Ex: compensator bellows, curved tube... Boundary conditions: Release some degrees of freedom Ex: Rotary joint, slide link Material with high Re (yield stress) or Rm (Ultimate stress) 2013/10/02 Curved tube (lyre) MAX School P. 36 THERMAL CONTRACTIONS AND STRESSES Example: Support rod between the helium vessel and the vacuum vessel 1. Temperature profile in the rod: T A Q x A λ( T).dT L MECHANICAL ASPECTS T1 Helium vessel T T2 λ( T).dT Cst 300 K 4K T1 0 2. Vacuum vessel L x Contraction of the rod: Cutting the rod in several sections, each defined by an average temperature: DL 3. DLi L 293 i LTi For L=400mm: Contraction of the helium vessel: For R=150mm: DR = a . R . DT 4. AISI 304L: G10: TIA6V: DL = 0.67 mm DL = 0.47 mm DL = 0.36 mm AISI 304L: DR = 0.38 mm Titanium: DR = 0.19 mm Thermal stress in the rod: D L DR E E L293 2013/10/02 (Helium vessel and vacuum vessel are supposed infinitely rigid) For Helium vessel AISI 304L: Rod in AISI 304L : = 525 MPa Rod in TIA6V: = 200 MPa MAX School P. 37 THERMAL CONTRACTIONS AND STRESSES Example: Support posts of MAX cryomodule Complex shape FEM analysis (behaviour during cool down) 1. Cavity Sliders Displacements at 2K – Stationary state: MECHANICAL ASPECTS ~ 3K DZ ~ 80K ~ 295K 2. ~ 10K Invar Rods Table Slider DZ DX : 0.1 mm DX : 0.4 mm DX : 3,5 mm Fixed Point Mobile Point Transient temperature gradients during the cooling down: Non uniform temperature of the table during the cooling down due to the non-balanced flow in the table cooling tubes 80K 150K 300K Transient state Stationary state 2013/10/02 MAX School DT max dX dY dZ V.M. 70 K (150-80) 3,4 mm 2,7 mm 1 mm 43 MPa 0 (80-80) 3,4 mm 1,6 mm 1 mm 50 MPa P. 38 EXTERNAL PRESSURE The external pressure generates on the walls of the vacuum vessel: Some deformations Risk of misalignment Some compressive stresses Risk of buckling MECHANICAL ASPECTS Each country has an applicable construction standard norm for the pressure vessels: Requirements for the design, the materials, the fabrication, the control tests. Ex: CODAP (France), European norm EN 13445, ASME(United States). Patm P=0 In the CODAP: • Classification of the pressure vessels according to the volume, the maximum allowable pressure and the nature of fluid. • A vacuum vessel does not fall into a risk category but the design and the fabrication follows the rules. Theses requirements are applicable for the design of: the vacuum vessel, the nozzles, the flanges and the bellows. Determine the critical buckling pressure: For simple shapes: • Using of design by formulae (CODAP, European norm) with a safety factor (takes into account the manufacturing defects: geometry, materials) • Analytical formulae (Roark) without safety factor For more complex shapes: • Finite Element Model analysis 2013/10/02 MAX School P. 39 EXTERNAL PRESSURE Example: unstiffened cylindrical vacuum vessel Material: Steel P235GH NF EN 10028-2 External diameter De: 800mm Length L: 6500mm Thickness: 10mm L De MECHANICAL ASPECTS CODAP: Calculation of the maximal allowable pressure Pa 4 B K 3 De / e K=1 : for normal operation K=1.35 : for exceptional operation - From a chart, determine the coefficient A = f( L De ) A 0.0002 , De e - From a chart, determine the coefficient B = f(A, material, T°) B 20 ( MPa) Pa = 0,33 MPa Roark Formulae: Calculation of the critical buckling pressure E e2 1 e2 Pcrit 0,807 4 L R 1 2 R 2 (Formulae available for short tube) Pcrit = 1,04 MPa Safety factor ~ 3: Pcrit (Roark) = 3,15 x Pa (CODAP) 2013/10/02 MAX School P. 40 EXTERNAL PRESSURE Example: SPL Short Test Cryomodule Top cover Material: Steel type P235GH External diameter De: 800mm Length L: 7000mm Thickness: 10mm (bottom) / 6mm (top) Flat flanges + O-ring Complex shape FEM analysis Bottom part MECHANICAL ASPECTS Linear buckling SPL Cryomodule (last version) Pcrit=23 bars (no safety factor) Extended study: Non linear buckling • Elasto-plastic material • Introduction of a geometrical defect Elastic material Elasto-plastic material Non linear buckling: Pcrit=8 bars Linear buckling: Pcrit=42 bars 2013/10/02 SPL cryomodule (old version) MAX School Buckling P. 41 CONTENTS INTRODUCTION BASIC FUNCTIONS MAIN COMPONENTS THERMAL ASPECTS MECHANICAL ASPECTS DIFFERENT CONCEPTS OF SUPPORTING ASSEMBLY PROCESS CRYOGENIC SCHEME OF A CRYOMODULE 2013/10/02 MAX School P. 42 DIFFERENT CONCEPTS OF SUPPORTING All structural supports of the components inside the vacuum vessel (cavities, shields...) DIFFERENT CONCEPTS OF SUPPORTING Whatever the type of support, the required functions are: To be a transition from the room temperature to a low temperature Limit the conduction heat transfers Thin and long structure Low conductivity material Supporting the components Position accuracy and preserving the stability of the cold mass Have a sufficient stiffness Limit thermal contractions and stresses Thick and massive structure The mechanical design of the supports depends on 2 technical contradictions 2013/10/02 MAX School P. 43 DIFFERENT CONCEPTS OF SUPPORTING Tie rods Compressive posts Vacuum vessel GRP with support posts Vacuum vessel Tie rods Support posts DIFFERENT CONCEPTS OF SUPPORTING Vacuum vessel Cold mass Cold mass Gas Return Pipe Cold mass Compressive posts Space frame Others ... Vacuum vessel The choice depends on: Tie rods Cold mass Pad supports Spaceframe • Assembly methods • Alignment strategy (warm / cold / inside / outside) • Cold mass weight (LHC) • Length of the string of cavities • Cryogenic distribution system (large GRP) • Team member’s experience •... There is no only one solution... 2013/10/02 MAX School P. 44 DIFFERENT CONCEPTS OF SUPPORTING TIE RODS Using of the antagonist rods • Preservation of the alignment in the plane formed by the rods: The rods have the same thermal contraction • Limitation of thermal stresses: the rod does not undergo the thermal contraction of the cold mass • Longer supports: Limit the conduction heat transfers Vacuum vessel Identical DL Cold mass Join the rods to the vacuum vessel Possibility to align after cooling down Example: Cryomodule B - SPIRAL2 Antagonist rods in horizontal o To adjust lateral alignment o To maintain the lateral alignment of the cavity 2013/10/02 Vertical rods o To support the weight o Vertical displacement of the cavity to anticipate for alignment MAX School P. 45 COMPRESSIVE POSTS DIFFERENT CONCEPTS OF SUPPORTING Using of some pad supports (with table) • The alignment of the string of cavities is realized outside the vacuum vessel • The alignment is then realized by adjusting the vacuum vessel with an external referential (transfer beam axis) Vacuum vessel Cold mass Use sliding supports and invar rod • The thermal contractions of the table is not transmitted to the cavity • Longitudinal position of the cavity is fixed by the invar rod Pad supports Example: MAX Cryomodule for spoke cavities o To adjust alignment Sliding support o To maintain alignment Invar rod o To maintain longitudinal alignment of the cavity 2013/10/02 Sliding table o To maintain alignment o To support the weight adjustable pods o Vertical displacement of the cavity to anticipate for the alignment MAX School P. 46 GRP WITH SUPPORT POSTS Support posts DIFFERENT CONCEPTS OF SUPPORTING Use Helium GRP as structural support • Large diameter pipe (because of pressure drop) Use composite thermalized support posts • At the centre: support fixed to the vessel • At the extremities: sliding supports for removing the effect of thermal contractions of the GRP Gas Return Pipe Vacuum vessel Cold mass Use sliding supports and invar rod • The thermal contractions of the GRP are not transmitted to the cavity • Longitudinal position of the cavity is fixed by invar rod Example: TTF Tesla Test Facility cryomodule Same solution for XFEL and ILC Support post Vacuum vessel GRP Invar rod 2 phase pipe Sliding support Coupler port 2013/10/02 MAX School 70K shield 4K shield Cavity P. 47 DIFFERENT CONCEPTS OF SUPPORTING SPACE FRAME Using of a space frame • The alignment of the string of cavities is realized outside the vacuum vessel • The alignment is then realized by adjusting the vacuum vessel with an external referential (transfer beam axis) Using of the antagonist rods Preserve the alignment of the cavities Vacuum vessel Tie rods Spaceframe Cold mass Pad supports Example: ESS Cryomodule for elliptical cavities (solution type SNS) Biphasic He pipe Spaceframe (300K) 50K Thermal shield Supporting rods He tank & Cavity Positioning jacks (3 at 120°) Coupler Vacuum vessel Door knob and RF wave guide 2013/10/02 MAX School P. 48 OTHER: SUPPORTING BY POWER COUPLER DIFFERENT CONCEPTS OF SUPPORTING Using of the double walled tube of the power coupler as support • Provides the alignment of each cavity along beam axis (fixed point) Using of the inter-cavity supports • Relative sliding between adjacent cavities along the beam axis • Provides a second vertical support (limits vertical self-weight sag) Example: SPL SHORT CRYOMODULE Inter-cavity supports RF coupler double-walled tube flange fixed to vacuum vessel 2013/10/02 MAX School P. 49 CONTENTS INTRODUCTION BASIC FUNCTIONS MAIN COMPONENTS THERMAL ASPECTS MECHANICAL ASPECTS DIFFERENT CONCEPTS OF SUPPORTING ASSEMBLY PROCESS CRYOGENIC SCHEME OF A CRYOMODULE 2013/10/02 MAX School P. 50 ASSEMBLY STEPS ASSEMBLY PROCESS Inside the clean room • Assembly of the string of cavities with its power couplers with a preliminary alignment Outside the clean room: Insertion of all components inside the vacuum vessel • Assembly of the other equipments of the string of cavities: Cold tuning system, magnetic shield, instrumentation,... • Assembly of the thermal shields, cryogenic distribution lines,... • Insertion inside the vacuum vessel • Procedure of alignment For each step, it’s necessary to provide: - Some specific tooling - Some suitable infrastructures 2013/10/02 MAX School P. 51 ASSEMBLY PROCESS OF CRYOMODULE B – SPIRAL2 Inside the clean room: Assembly of the cavity with: - the power coupler - the cold tuning system (CTS) CTS Insertion and connections of the cavities in the intermediate part of the vacuum vessel: ASSEMBLY PROCESS Cavities Clean room handling apparatus 2013/10/02 Power coupler One part of the vacuum vessel MAX School Transport carriage P. 52 ASSEMBLY PROCESS OF CRYOMODULE B – SPIRAL2 Outside the clean room: ASSEMBLY PROCESS Magnetic shield & MLI Closing of the top cover Raising of the assembly 2013/10/02 Top plate with cryogenic line, part of thermal shield Withdrawal of the carriage MAX School thermal shield Finish with the bottom of the vacuum vessel Cylinder of the vacuum vessel Ready to be tested P. 53 ASSEMBLY PROCESS OF MAX CRYOMODULE Outside the clean room: Inside the clean room: Assembly of the string of cavities with the power couplers on the sliding table Pre-alignment Finalization of the dressing of the cavities: - Cold tuning system, - Magnetic shield, - Some cryogenic pipes, - thermal shield ASSEMBLY PROCESS Adjustment of alignment Cryostating: - Displacement of the vacuum vessel for the insertion - Assembly of supporting posts,... - Closing of the vacuum vessel 2013/10/02 MAX School P. 54 ASSEMBLY PROCESS OF ESS SPOKE CRYOMODULE Outside the clean room: Inside the clean room: Assembly of the string of cavities with the power couplers on a specific tooling Finalization of the dressing of the cavities: - Magnetic shield, - Some cryogenic pipes, - Supporting rods - Thermal shield ASSEMBLY PROCESS Pre-alignment Cryostating: - Insertion in the vacuum vessel - Assembly of supporting rods - Cold tuning system, cryo. Pipes,... - Closing of the vacuum vessel Adjustment of alignment 2013/10/02 MAX School P. 55 ALIGNMENT Objective: Align the beam tubes of all cavities along the beam axis. The beam tubes are not accessible when the cryomodule is close Transfer the beam tubes axis: External references (new fiducials) ASSEMBLY PROCESS 1. Align the cavities inside the cryomodule 2. Align the cryomodule with respect to the others Measurement equipments: retroreflector Laser tracker Total station (Theodolite) 2013/10/02 MAX School Taylor Hobson sphere P. 56 ALIGNMENT STRATEGY FOR CRYOMODULE B SPIRAL2 Offsets of the beam axis on the helium vessel: The tolerated maximum static errors for the global alignment are: - ± 1 mm for the displacement of the cryomodules - ± 0.3° for the rotation (X,Y) of the cryomodules 2nd offset axis 1st offset axis ASSEMBLY PROCESS Beam axis 2nd offset axis 1st offset axis Fiducialization bench (=section of the linac structure): - Alignment of the cavities in the cryomodule - Offset the beam axis on the support of the cryomodule Beam axis 2 Offset axes of the cavity Offset axis of the cryomodule Reference axis for alignment of all components on the accelerator 2013/10/02 MAX School P. 57 ALIGNMENT OF SPL CRYOMODULE Example of budget tolerance: SPL Cryomodule ASSEMBLY PROCESS Specific tooling for the alignment of the string of cavities: 4 spheres by cavity to adjust the alignment Step Cavity and He vessel assembly ± 0.1 mm Supporting system assembly ± 0.2 mm Vacuum vessel construction ± 0.2 mm Transport and handling (± 0.5 g any direction) N.A. ± 0.1 mm Testing/operation Vacuum pumping Cool-down RF tests Warm-up Thermal cycles ± 0.2 mm Cryo-module assembly 2013/10/02 BUDGET OF TOLERANCE Sub-step Tolerances (3σ) MAX School Total envelopes Positioning of the cavity w.r.t. external referential ± 0.5 mm Reproductibility/ Stability of the cavity position w.r.t. external referential ± 0.3 mm P. 58 CONCLUSION The mechanical design of a cryomodule depends on a variety of parameters that need some knowledge in: CONCLUSION Mechanical, thermal, vacuum and cryogenics. At IPNO Laboratory, the mechanical design of the cryomolules is assumed by the design office: - 6 engineers - 7 draughtman designers Supported by other colleagues from the Accelerator Division (total: 90 persons): - Expert in cryogenics and vacuum - Expert in RF cavity design - Expert in beam dynamics 2013/10/02 MAX School P. 59 References • H. Saugnac, IPN Orsay, “Cryostat : construction et mise en oeuvre”, Journées cryogéniques d’Aussois, 2003 • Paolo Pierini, INFN-Milan, “overview of cryomodules for proton accelerators”, ESS Bilbao initiative workshop, 2009 • N. Ohuchi, KEK, “Fundamentals of cryomodule”, SRF 2009 tutorial program, 2009 • T. H. Nicol, Fermilab, “Fundamentals of Cryomodule Design: Theory and Practice, Part II – Mechanical Considerations”, SRF 2011 tutorials • V. Parma, CERN, “Cryostat design II: Application to cryostat design”, Cryostat Design Seminar at GSI, 2005 • H. Saugnac, IPN Orsay, “Design review of the SPIRAL2 cryomodule B”, 2008 • P. Duthil, S. Rousselot & P. Duchesne, IPN Orsay, “ SPL Cryomodule Conceptual Design Review - Vacuum Vessel and Assembly Tooling”, 2011 • D. Reynet, P. Duthil & S. Bousson, IPN Orsay, “Engineering Design of the ESS Spoke Cryomodule”, SLHIPP meeting, 2013 • G. Olivier & J.P. Thermeau, IPN Orsay, “ESS Cryomodule for elliptical cavities (Medium and high beta)”, SLHIPP meeting, 2013 2013/10/02 MAX School P. 60 THANK YOU FOR YOUR ATTENTION 2013/10/02 MAX School P. 61