Lecture 22

advertisement

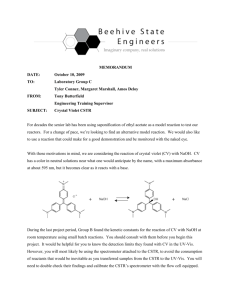

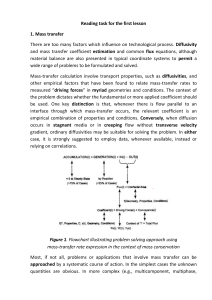

Lecture 22 Chemical Reaction Engineering (CRE) is the field that studies the rates and mechanisms of chemical reactions and the design of the reactors in which they take place. Today’s lecture Blowout Velocity CSTR Explosion Batch Reactor Explosion 2 Last Lecture CSTRs with Heat Effects 3 Energy balance for CSTRs Q W S n F i0 i 1 dT dt 4 n d Eˆ sys i 1 dt H i 0 Fi H i Q W Fi 0 C Pi T Ti 0 H Rx T rA V S NC i Pi Energy balance for CSTRs dT dt FA 0 N i C Pi G T R T G T rA V H Rx R T C PS 1 T TC 5 UA FA 0C P 0 TC T0 Ta 1 Steady State Energy Balance for CSTRs At Steady State dT dt dN A 0 dt rA V FA 0 X G T R T 0 H Rx FA 0 X FA 0 i C P T T 0 UA T T a 0 i 6 Energy balance for CSTRs Solving for X i C Pi T T 0 X H UA FA 0 T T a X EB Rx Solving for T T 7 FA 0 X H Rx UAT a FA 0 i C Pi T 0 UA FA 0 i C Pi Energy balance for CSTRs R T C PS 1 T TC R(T) Increasing T0 T 8 Variation of heat removal line with inlet temperature. Energy balance for CSTRs R T C PS 1 T TC κ=∞ κ=0 R(T) Increase κ Ta 9 T0 T Variation of heat removal line with κ (κ=UA/CP0FA0) V FA 0 X rA X , T A B 1) Mole Balance: 2) Rate Law: 10 V FA 0 X rA rA kC A 3) Stoichiometry: 4) Combine: C A C A 0 1 X V FA 0 X kC A 0 1 X k 11 C A00X kC A 0 1 X X 1 X V FA 0 X kC A 0 1 X k X k 1 k 12 kC A 0 1 X X 1 X G T X H Rx C A00X E RT Ae 1 Ae Ae E RT E RT 1 Ae E RT H Rx Variation of heat generation curve with space-time. 13 Finding Multiple Steady States with T0 varied 14 Finding Multiple Steady States with T0 varied 15 Temperature ignition-extinction curve 16 Heat Effects Isothermal Design Stoichiometry Rate Laws Mole Balance 17 Heat Effects Isothermal Design Stoichiometry Rate Laws Mole Balance 18 Example B: Liquid Phase CSTR Same reactions, rate laws, and rate constants as example A A 2 B C (1) 2 r1A k1A C A C B NOTE: The specific reaction rate k1A is defined with respect to species A. 3C 2 A D ( 2 ) 3 C r2C k 2C C C 2 A NOTE: The specific reaction rate k2C is defined with respect to species C. 19 Example B: Liquid Phase CSTR The complex liquid phase reactions take place in a 2,500 dm3 CSTR. The feed is equal molar in A and B with FA0=200 mol/min, the volumetric flow rate is 100 dm3/min and the reation volume is 50 dm3. Find the concentrations of A, B, C and D existing in the reactor along with the existing selectivity. Plot FA, FB, FC, FD and SC/D as a function ofV 20 Example B: Liquid Phase CSTR Solution Liquid CSTR Mole Balances: 21 (1) f C A 0 C A 0 0 C A rA V (2) f C B 0 C B 0 0 C B rB V (3) f C C 0 C C rC V (4) f C D 0 C D rD V Net Rates: (5) rA r1A r2 A Selectivity If one were to write SC/D=FC/FD in the Polymath program, Polymath would not execute because at V=0, FC=0 resulting in an undefined volume (infinity) at V=0. To get around this problem we start the calculation 10-4 dm3 from the reactor entrance where FD will not be zero and use the following IF statement. (15) 22 S˜ C D if V 0.001 F C then else F D 0 Selectivity Stoichiometry: (16) C A FA 0 (17) C B FB 0 (18) C C FC 0 (19) C D FD 0 Parameters: 23 (20) 0 100 dm (21) k 1 A 10 dm (22) k 2 C 15 dm 3 min 3 mol 3 mol 2 4 min min Example 1: Safety in Chemical Reactors H 2 O Gas N O 2 T0 200 F m A0 310 lb h 17 % H 2 O P 200°F Liquid 83 % NH 4 NO 3 510°F Ta 24 X NH 4 NO 3 M 500 lb NH 4 NO 3 N 2O 2H 2O Ta 0 Example 1: Safety in Chemical Reactors NH 4 NO 3 2 H 2 0 N 2 O A 2B C dN A F A 0 F A rA V B F B 0 F B rB V t dN t dN C t 25 FC 0 FC rC V FA0 FI0 A Example 1: Safety in Chemical Reactors T t Qg Qr NC i (only A in vat, B, C are gases) Pi Qg Qr N A C PA Q g ( rA V )( H rxA ) Q r FA 0 C PA ( T T0 ) B ( H B H B 0 ) UA ( T Ta ) If the flow rate shut off, the temperature will rise (possibly to point of explosion!) 26 Rearranging: Q dT Q g r rA V H Rx FA 0 i H i H i 0 UA T Ta N i C Pi dt Qg Qr N i C Pi Additional information (approximate but close to the real case): H Rx 336 Btu / lb ammonium C P 0 . 38 Btu / lb ammonium C P 0 . 47 Btu / lb ofsteam 27 rA V kC A V k M V nitrate at 500 F ( cons tan t ) nitrate F nitrate F V kM ( lb / h ) dT Q FA 0 C PA T T 0 FA 0 B H B g H B 0 rA V H Rx FA H Avap N A C PA dt Q Q Q g r 1 r 2 dT rA V H Rx FA 0 C PA T T0 B H B g H B 0 FA H Vap UA T Ta N A C PA dt Complete conversion FA = 0 Q g Q r 1 Q r 2 N A C PA dT dt Batch Reactors with Heat Effects Single Reactions Q g rA V H Rx Multiple Reactions Q g r ij H Rxij V 28 Risk Rupture Q r 2 mÝvap H vap dT dt Qg Qr N i C Pi Q r 1 UA T T a Keeping MBAs Away From Chemical Reactors The process worked for 19 years before they showed up! Why did they come? What did they want? 29 Nitroaniline Synthesis Reaction NO2 NO2 Cl NH2 + ONCB 30 + 2NH3 Ammonia + Nitroanaline + NH4Cl Ammonium Chloride Nitroaniline Synthesis Process NH3 in H2O ONCB Autoclave 175 oC ~550 psi O-Nitroaniline Product Stream NH3 Separation Filter Press To Crystallizing Tanks 31 “fast” Orange Nitroaniline Synthesis Reactor Old 3 kmol ONCB 43 kmol Ammonia 100 kmolWater V = 3.25 m3 32 Nitroaniline Synthesis Reaction NO2 NO2 Cl NH2 + ONCB + 2NH3 Ammonia + Nitroanaline + Batch Reactor, 24 hour reaction time 33 Management said:TRIPLE PRODUCTION NH4Cl Ammonium Chloride MBA Style Nitroaniline Synthesis Reactor 34 New 9 kmol ONCB 33 kmol Ammonia 100 kmolWater V = 5 m3 Temperature oC Temperature-time trajectory 400 Cooling Restored 175 Isothermal Operation 9:55 t=0 35 10:40 10:50 fuse midnight 12:18 Temperature-time trajectory dT dt UA ( T 0 T ) ( rA V )( DH ) N A 0 C pA N B 0 C pB N W C pW dT dt 36 rx Qg Qr NC p End of Lecture 22 37