Course:

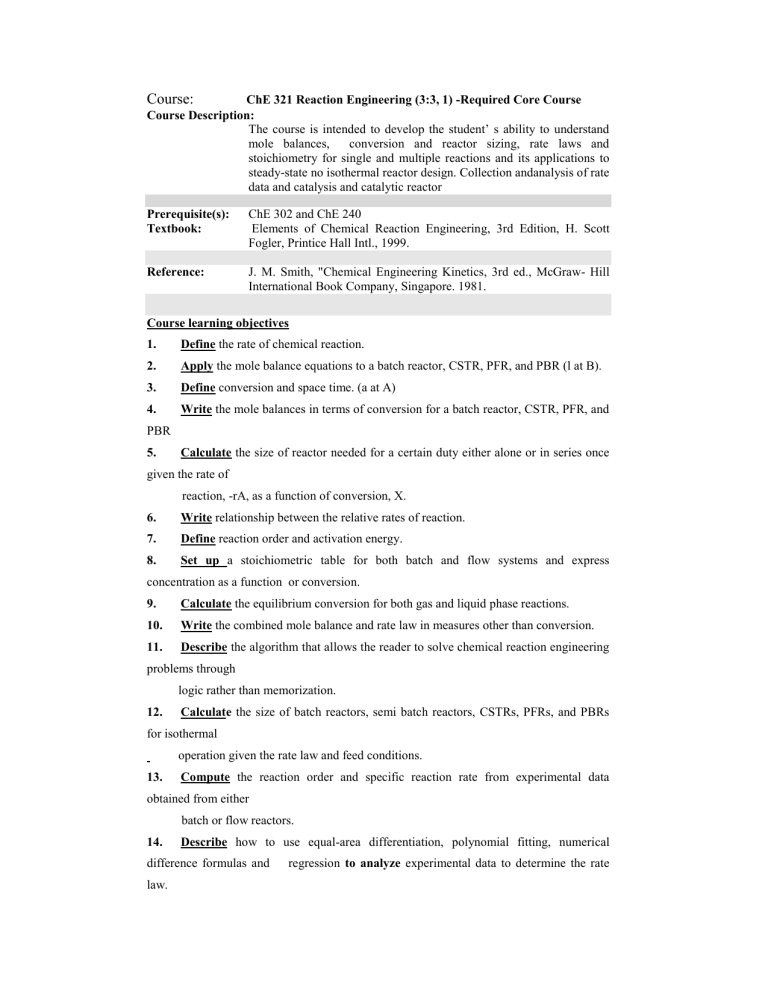

Course: ChE 321 Reaction Engineering (3:3, 1) -Required Core Course

Course Description:

The course is intended to develop the student’ s ability to understand mole balances, conversion and reactor sizing, rate laws and stoichiometry for single and multiple reactions and its applications to steady-state no isothermal reactor design. Collection andanalysis of rate data and catalysis and catalytic reactor

Prerequisite(s): ChE 302 and ChE 240

Textbook: Elements of Chemical Reaction Engineering, 3rd Edition, H. Scott

Fogler, Printice Hall Intl., 1999.

Reference: J. M. Smith, "Chemical Engineering Kinetics, 3rd ed., McGraw- Hill

International Book Company, Singapore. 1981.

Course learning objectives

1.

Define the rate of chemical reaction.

2.

Apply the mole balance equations to a batch reactor, CSTR, PFR, and PBR (l at B).

3.

Define conversion and space time. (a at A)

4.

Write the mole balances in terms of conversion for a batch reactor, CSTR, PFR, and

PBR

5.

Calculate the size of reactor needed for a certain duty either alone or in series once given the rate of

reaction, -rA, as a function of conversion, X.

6.

Write relationship between the relative rates of reaction.

7.

Define reaction order and activation energy.

8.

Set up a stoichiometric table for both batch and flow systems and express concentration as a function or conversion.

9.

Calculate the equilibrium conversion for both gas and liquid phase reactions.

10.

Write the combined mole balance and rate law in measures other than conversion.

11.

Describe the algorithm that allows the reader to solve chemical reaction engineering problems through

logic rather than memorization.

12.

Calculate the size of batch reactors, semi batch reactors, CSTRs, PFRs, and PBRs for isothermal

operation given the rate law and feed conditions.

13.

Compute the reaction order and specific reaction rate from experimental data obtained from either

batch or flow reactors.

14.

Describe how to use equal-area differentiation, polynomial fitting, numerical difference formulas and regression to analyze experimental data to determine the rate law.

15.

Describe how the method of half lives, and of initial rate, are used to analyze rate data.

16.

Describe two or more types of laboratory reactors used to obtain rate law data along with their

advantages and disadvantages.

17.

Define different types of selectivity and yield.

18.

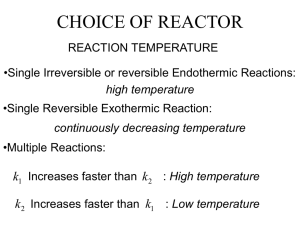

Select the type of the reaction system that would maximize the selectivity of the desired product given

the rate laws for all the reactions occurring in the system.

19.

Describe the algorithm used to design reactors with multiple reactions.

20.

Calculate the size of reactors to maximize the selectivity and to determine the species concentrations

in a batch reactor, semi-batch reactor, CSTR, PFR, and PBR, systems.

21.

Describe the algorithm for CSTRs, PFRs, and PBRs that are not operated isothermally.

22.

Calculate the size of adiabatic and no adiabatic CSTRs, PFRs, and PBRs needed for a certain duty.

23.

Define a catalyst, a catalytic mechanism and a rate limiting step.

24.

Describe the steps in a catalytic mechanism and how one goes about deriving a rate law and a

mechanism and rate limiting step consistent with the experimental data.

25.

Calculate the size of isothermal reactors for reactions with Langmuir-Hinschelwood kinetics.

Topic Covered During Class:

Mole Balances

Conversion and Reactor Sizing

Rate Law and Stoichiometry

Isothermal Reactor Design

Collection and Analysis of Rate Data

Multiple Reactions

Class Schedule :

Lecture :

Tutorials :

Steady-State Non-isothermal Reactor Design

Catalysis and Catalytic Reactors

Three 1 Hour sessions per week

One 3 Hours session per week

Duration in weeks

1

2

2

2

2

1

2

2

Course Contribution to professional Component

Engineering Science: 75%

Engineering Design: 25%

Relationship to Program Outcomes:

Program

Outcomes

ABET Outcomes Program

Criteria a b c d e f g h i j k l

Highest

Attainable Level of Learning

Prepared by:

Last updated:

2 2 3 1 1

Dr. Yahia A. Al-hamed

May 2007