Quality Control in Blood Management

advertisement

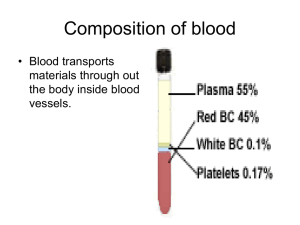

Quality Control Procedures During Autotransfusion AmSECT New Advances in Blood Management Meeting Seattle, Washington September 8, 2011 John Rivera 1 Autotransfusion Quality Control Procedures • AABB 4th Edition of Standards for Perioperative Autologous Blood Collection and Administration • FDA, Joint Commission, CAP, CLIA, OSHA, State Departments of Health and Ministry of Health for other countries (all should defer to the AABB Standards) • New devices must be validated in-vitro prior to placing them into use (3.3) 2 Autotransfusion Quality Control Procedures • Standards: 5.1.2 – “A program of quality control shall be established that is sufficiently comprehensive to insure that reagents, equipment and methods function as expected. Results shall be reviewed and corrective action taken when appropriate.” • Periodic Quality Control is performed to assess instrument function and operator competency. • Exact frequency of testing is not documented, although most facilities examine individual operators somewhere between once a month to once a quarter. AABB does NOT mandate testing of every procedure as well as every unit of blood collected and processed. 3 Medical Director for Autotransfusion Services • “The perioperative program shall have a medical director who is a licensed physician and who is qualified by training and/or experience. The medical director shall have responsibility and authority for all policies, processes and procedures.” Standards: 1.1.1 • “The medical director shall participate in the development of policies, processes and procedures regarding the collection and administration of perioperative products, including patient selection and preparation of the patient for surgery.” Standards: 5.2.2 4 Autotransfusion Quality Control Procedures • With the procedure: – Establish a protocol that includes: • Suitable cases, surgical applications and contraindications must be well understood, see November 2010 Guidelines for Blood Recovery and Reinfusion in Surgery and Trauma, Appendix 1 • Applicable patient parameters • Ideal operating parameters (flow rates, vacuum levels, wash volumes, etc.) 5 Autotransfusion Quality Control Procedures • With the product: – Adequate testing of all components (Standards: 5.1.2) • RBC: hematocrit, residual potassium, residual plasma protein, volume processed and returned, residual anticoagulant and free plasma hemoglobin if available • The goal is to remove 95% of residual potassium or plasma protein (Collection Reservoir MUST be sampled before processing and that product MUST be compared to Holding Bag contents) • Removal rate for free plasma hemoglobin or residual anticoagulant should be 90% • A clear effluent line is not an adequate indicator of washout • Periodic quality control testing MUST be performed 6 Autotransfusion Quality Control Sampling • Atraumatic and aseptic, avoid needles and negative pressure • Visit with the laboratory to advise them what is coming • Transfer samples in containers that do NOT already contain anticoagulants or preservatives • Perform testing in a timely manner, especially if using resdiual potassium as the measure of washout • Use non-serum based testing devices • Label samples appropriately • Post wash samples can be maintained for an extended time via transfer bag segments 7 Autotransfusion Quality Control Procedures • With the product (Standards: 5.1.2) – Platelets: count and volume if performing sequestration and/or platelet gel (Platelet function if that testing is available), Visual testing, “definition of acceptable results”, compare pre-counts in blood and citrate syringes versus post-counts in PRP syringes (not the chart and not patient whole blood) – “Bacterial contamination of recovered blood is routine and little correlation is found with adverse clinical sequelae” (per November 2010 Guidelines) – Ideal cellular removal of activated platelets and white cells should be greater than 90% in washed, recovered autotransfusion products 8 Prevention of Air Embolism (5.4.3) • Use a Transfer Bag, remove air, tie knots and disconnect and exchange that bag for a new one • Or disconnect the Holding Bag after insuring that ALL residual air has been removed. • Recovered product must be inspected (by the operator) prior to release for clots, discoloration, fat, particulate, hemolysis or fluid interface (Standards: 5.4.2.1) • “Perioperative products intended for transfusion shall be transfused through a filter designed to retain particles that are potentially harmful to the patient.” (Standards: 5.4.5.1) Most manufacturers recommend the use of a 40 micron microaggregate filter in addition to the standard blood administration set 9 Conclusion • • • • • • • There MUST be written and appropriately reviewed policies and procedures for autotransfusion and the autotransfusion program MUST have a Medical Director Regular quality control testing of the recovered washed Packed Red Blood Cells MUST be performed The blood in the Collection Reservoir MUST be sampled and tested for direct comparison to the washed blood in the Holding Bag to confirm acceptable levels of contaminant removal Tests completed will depend upon the available technology at each facility Quality Control testing MUST be performed in a frequent manner and frequency of testing should be determined by each individual facility New autotransfusion devices MUST be validated using the same Quality Control testing procedures prior to placing them into clinical use Consider sending out occasional samples for “Gold Standard” testing for residual free plasma hemoglobin and residual anticoagulant 10