8b.1 Aaron Toneys-TR.. - Trb

advertisement

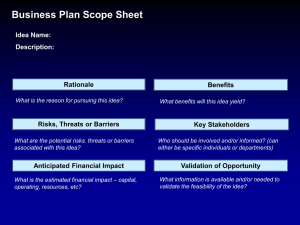

SESSION: GREEN WASTE AND STANDARDS June 18, 2014, 4:00 pm. Track B THE STATE OF THE INDUSTRY FOR WASTE RECOVERY TECHNOLOGIES: A LOOK AT RELEVANT TECHNOLOGIES, THEIR SCALES AND FEASIBILITY FOR LARGE TRANSIT, TURNPIKE, AND HIGHWAYS SYSTEM Aaron Toneys, Associate, Good Company PROACTIVE ENVIRONMENTAL MANAGEMENT SYSTEM Mike Yesconis, Environmental Information Technology, Co-author S. Babusukumar. Weston LANDFILL REUSE ASTM STANDARD Marty Rowland, PhD P.E., Third Leg Consultants & Amanda Ludlow, Principal Scientist, Roux Associates SESSION: GREEN WASTE AND STANDARDS The State of The Industry for Waste Recovery Technologies: A Look at Relevant Technologies, Their Scales and Feasibility for Large Transit, Turnpike, and Highways System Aaron Toneys. Associate, Good Company Policy makers and waste management professionals are beginning to recognize the nexus between landfilled solid waste and our need for domestically produced, low-carbon vehicle fuels. Pre and post-consumer food waste and difficult-to-recycle plastics are significant waste streams with potential to reduce the burden on landfills, capture the highest and best use for materials, reduce greenhouse gas emissions and provide new sources of revenue through integrated waste management. This presentation will introduce a 101 on waste recovery technologies and their potential to reduce costs and/or generate revenue and improve local and global environmental conditions. The technology focus will be on vehicle fuel production through AD and plastics-to-oil technologies. The presentation will conclude with an introduction to the significant operating and market variables to consider when assessing the feasibility of these technologies for a transportation agency. This discussion will be supported by with examples from various materials recovery feasibility studies that Aaron Toneys and his research team has performed for domestic and international agencies and materials management companies. All participants will leave with a one-page checklist for feasibility assessment for participating in or operating these technologies. Aaron Toneys, Associate of Good Company, provides clients with technical research, triple bottom line assessments, tool development, and greenhouse gas inventories. Mr. Toneys focuses on alternative fuels and the materials and energy recovery industries. His work has included technology and system feasibility studies for anaerobic digestion, plastics-to-oil pyrolysis and Fischer– Tropsch diesel. He is currently serving on workgroups to address life-cycle materials management, including Oregon DEQ’s Materials Management Workgroup to address goals and measures and EPA’s West Coast Climate & Materials Management Forum to develop a government purchasing toolkit. MAKING SUSTAINABILITY WORK WORK MAKING SUSTAINABILITY State of the Industry for Waste Recovery Technologies Anaerobic Digestion and Plastic-to-Crude Oil Presented by Aaron Toneys Associate 4/13/2015 Good Company 65 Centennial Loop, Suite B Eugene, Oregon 97401 3 www.goodcompany.com phone 541.341.4663 fax 541.341.6412 Overview • Purpose: Discuss the highest and best use for organics and difficult to recycle plastics • Technology 101 Anaerobic digestion of organic materials Plastics-to-crude oil pyrolysis • Variables to assess feasibility • Potential for fuel production 4 Our Firm, Good Company • Sustainability research and consulting firm • Mission-driven, for-profit 5 Highest and Best Use Hierarchy (revised) Reduce Consumption & Product Stewardship Reuse Recycle / Compost Conversion Technologies: Energy and Chemical Recovery Incineration & Co-Firing Land fill 6 What is Anaerobic Digestion (AD)? • Process: breaks down waste organic materials without oxygen that can produce energy, compost and environmental credits • Benefits: produces renewable energy, compost and environmental commodities (RECs, RINs, offsets); waste feedstock; landfill diversion; GHG reduction • Risks: feedstock sourcing, air and water emissions, permitting, logistical issues • Transportation-related uses: vehicle fuel to displace diesel costs; source of compost for operations; treatment method for organic wastes (e.g., mowed, animal moralities) 7 What is Anaerobic Digestion (AD)? 8 GHG Comparison of Organics Disposal Landfill Compost Anaerobic Digestor + Compost 35,000 GHG Emissions (MT CO2e) 25,000 15,000 5,000 -5,000 -15,000 -25,000 Transport & Operations + Fugitive Emissions + Energy Production Carbon Nutrient + Sequestration + Replacement = 9 Source: Good Company (2011). Managing Organics to Increase Margins and Carbon Benefits. Research presented at BioCycle 2011 conference in San Diego, CA. Net Emissions Methane Yield, by Feedstock Type 10 Source: This graphic was created based on Steppen, et al. Feedstocks for Anaerobic Digestion. Energy + Env. Credit Value / Ton Feedstock Value of AD Products, by Energy Use $60.00 Series3 Environmental Commodities Series1 Energy $50.00 $40.00 $30.00 $20.00 $10.00 $0.00 Heat CHP (electricity + heat) CNG* (NG value) 11 Feasibility Study. Source: Good Company (2011). Southern Oregon Biogas http://www.jswcd.org/Files/Biogas_Plant_Feasibility_Study-Full_Report.pdf CNG* (diesel value) Vehicle Fuel Cost Comparison 12 County Bioenergy Feasibility Study. Source: Tetra Tech and Good Company (2011). Tillamook http://www.co.tillamook.or.us/gov/solidwaste/(1)Documents/TillamookBioenergyFSFinalReport(03-12).pdf AD Feasibility Considerations • Feedstock quantity, composition and seasonality • Tip fees: >$50 / ton • Energy prices: Displacing owned vehicle fuel in general leads to greatest value. • Environmental commodity prices (REC, RIN, offset): RINs have offered greatest value in the last few years. Beware of variability due to new markets and policy change. • Facility Costs Construction: ~$1.5 million (5k tons/year facility) - ~$40 million (125k ton / year facility) Operations and Maintenance: $20 - $100 / short ton Grant opportunities • Facility Location: proximity to feedstock and markets Bulk compost: <50 miles from facility • Existing waste contracts for you and partners 13 What is Plastics-to-Crude Oil Pyrolysis? • Process: Anaerobic thermal conversion of difficult to recycle plastics into synthetic crude oil • Benefits: domestic fuel source, can be lower carbon, recovers storable energy, reduces landfilling, relative environmental performance will improve over time • Risks: over-sized facility, highly contaminated feedstocks, and permitting uncertainty. • Transportation-related uses: create value from plastic roadside waste that can’t be recycled, roadside and station waste, asphalt producers 14 Plastics-to-Crude Oil Pyrolysis Feasibility • State-level regulations for conversion technologies • Feedstock Plastic feedstock that are NOT otherwise recyclable Technology Capacity: 100 tons / year - 17,000 tons / year Composition: More LDPE and HDPE and less PET and PVC for most efficient, highest-yield conversion • • • • Production: ~80,000 barrels 17,000 ton / year facility Co-locate facility with feedstock source or refinery Crude oil price threshold: >$85 / barrel Costs Construction: $15 - $20 million (50 tons / day) Operations and Maintenance: ~$175 - $250 / ton of throughput ~1/3 of O&M = Balance of system 15 AD and Pyrolysis Potential vs. U.S. Use 200 Billion Gallons Pyrolysis AD 150 Gas + Diesel 100 50 0 2013 Gasoline and Diesel Use 16 Waste-to-Fuels (Estimated Potential) AD and Pyrolysis Potential vs. RFS 16 Pyrolysis AD RFS Quota Billion Gallons 12 8 4 0 2012 RFS Standard 17 Waste-to-Fuels Thank you Feel free to contact me: Aaron Toneys, Associate 541.341.GOOD (4663) x218 associate@goodcompany.com 18 Scope of Services MEASURE Product and Service Assessments Life-Cycle Assessment Enterprise Performance Assessment Greenhouse Gas Inventory Feasibility Studies and Financial Modeling MANAGE Decision Support Climate Adaptation and Mitigation MARKET Market Research and Positioning Business Plans Sustainability Reporting and Carbon Disclosure Sustainability Plans and Management Systems Business and Market Development Education and Training Public Engagement and Education Venture Capital Tool Development 19 Pyrolysis compared to Incineration 20 Carbon-Intensity of Pyrolysis Carbon Footprint of Agilyx Compared to Other Energy Recovery Affected Life-Cycle Stages Only Agilyx Plas c-toCrude-Oil Process 200 70 Agilyx Plas cto-Crude-Oil Process Crude extrac on and transport Final disposal: combus on 60 150 g CO2e / MJ Crude extrac on and transport Final disposal: combus on 50 40 30 20 g CO2e / MJ 10 - Vehicle Opera on Plas c + Fuel (Oil Sands) 100 Refining & Fuel transporta on Waste Collec on & Sor ng 50 Resin distribu on and product fabrica on Plas c + Fuel Plas c + Fuel Agilyx (Oil Sands) (US Avg Oil) (low-carbon) Raw material extrac on to resin manufacturing 21 Plas c + Fuel (US Avg Oil) Agilyx (low-carbon)