Ethylene Production From TN Fracked Natural Gas

advertisement

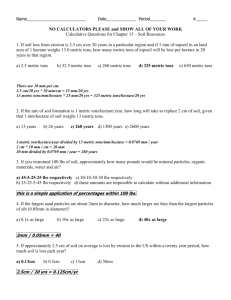

Ethylene Production From Tennessee Fracked Natural Gas University of Tennessee at Chattanooga ENGR 5910/ENCH 4300 4/26/2012 Brandon Dodd Valentine Mbamalu Outline • • • • • • • Introduction Design Basis Cracking Reaction Process Flow Diagram Equipment Design Project Economics Conclusion Introduction www.timesonline.com Design Basis • Analyze 500,000 metric tons Ethane feedstock per year • Feedstock will be considered as 100% Ethane • Negligible reaction byproducts not to be considered for this level of design Ethane Cracking Reaction Hydrogen Gas Byproducts Methane Propane Generalized Process Flow Diagram Steam Cracker • 170 MW heat duty • Modeled as 2 100MW separate pyrolysis furnaces • Each furnace 100 MW capacity • Operates at 80% capacity. Transfer Line Exchanger • Shell and Tube Model • 73 MW Heat Removed from Product Stream • 820 m2 Total Exchange Area • 2 Units in Series Distillation Columns • 3 Total Columns • 8 stage de-methanizer – 10m high – 3m diameter • 20 stage de-ethylenizer – 15m high – 3m diameter • 40 stage de-ethanizer – 27m high – 3m diameter Other Equipment Estimated • Quench Tower • Compressors • Refrigeration • Pumps • Fans Unit Cost Summary Unit C-101 C-102 K-101 E-101 E-102 E-103 F-101 H-101 H-102 P-101 R-101 T-101 T-102 T-103 V-101 Z-101 Unit Cost Estimation Summary Description # Units Cost (Millions) Compressor 1 2 Compressor 1 12.7 Drier 1 1.2 Transfer Line Heat Exchanger 1 0.5 Refrigeration Train 1 0.4 Regrigeration Train 1 0.6 Fans 20 0.3 Pyrolysis Furnace/Cracker 1 21.5 Pyrolysis Furnace/Cracker 1 12.6 Pump 10 2.9 Acetylene Converter 1 0.2 De-methanizer - tower 1 3.7 De-ethylenizer - tower 1 5.4 De-ethanizer - tower 1 9.3 Product Holding Tank 1 2.7 Quench Tower 1 2 Costs – In Millions • Capital Costs - $121 – Includes land cost • Total Annual Operating Costs - $617 – Utility Cost - $142 – Raw Material Cost - $475 – Labor Cost – estimated $1 Revenue – In Millions Total Yearly Revenue - $960 • Ethylene – 560,000 metric tons – $955 • Methane – 3000 metric tons – $0.7 • Propane – 3000 metric tons – $0.7 Revenue Vs. Cost 1000 900 800 M I L L I O N 700 600 500 400 300 200 100 0 Revenue Raw Mat. Utilities Labor Payback Period ENVIRONMENTAL IMPACT • Air pollution • Primary – Nitrogen dioxide, Particulate Matters, Volatile Organic Component . Secondary – Ozone . Incinerators Conclusions • • • • Costing based on key component Project is profitable Economic activities will receive boost Jobs and revenue to state and local gov.