Safety Culture & Safety Management

advertisement

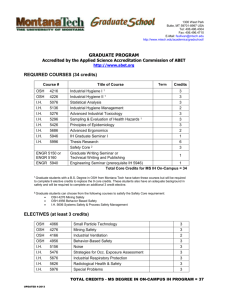

Summary Slide Tutorial 1 Safety Culture & Safety Management 1 Tutorial 1 Safety Culture & Safety Management SK Poon 2 Tutorial 3 Purpose of the tutorial The assignment How to tackle the Problems Action Strategies Critical issues Improvement opportunities Reflection Assignment No. 1 How significant is safety culture to the effective implementation of safety management? In attempting the assessment task, you should consider the following: 1. 2. 3. 4 In your opinion, how easy is it to establish a positive safety culture in an organization which has ineffective, mediocre or a negative safety culture? In your opinion, how can a poor safety culture be changed, or how can an effective, proactive safety culture be improved? From the readings, the modules you have consulted and your own experience, which are the safety management tools and practices that can introduce effective safety culture, or change a negative safety culture? Safety Culture – an overview Definition of “Safety Culture”? Why “Safety Culture”? Historical path from safety engineering to culture change (Simon & Leik) Stages of safety culture (Barrachough & Carnino. 1998) Management role & actions (Barrachough & Carnino. 1998) 5 Definition of TSM How about if you don’t know the answer? Tips: 6 Refer to the course materials provided Brain-storming through group discussion Ask an expert Conduct an intensive library/internet search using the right keywords and searching techniques Summarize the findings and make sense of the meaning Put it in your own words Put the new ideas into practice Review the results (reflection) Pre-tutorial Readings 7 Read Reading 3 - Goetsch, D.L. 1998, 'Establish a TSM culture', in Implementing Total Safety Management: Safety, Health, and Competitiveness in the Global Marketplace, Prentice Hall, pp 215-231, and Reading 10 - Simon, R.A. & S.I. 1996, 'Improving safety performance through cultural interventions', in Essentials of Safety and Health Management, ed. R.W. Lack, CRC Press Inc. U.S.A., pp. 521-534, and consider the questions set out in Assignment No. 1. 80-90% of all industrial accidents are attributable to 'human factors' "Investigations into major disasters such as Piper Alpha, Zeebrugee, Flixborough, Chapham Junction, and Chernobyl have revealed that complex systems broke down disastrously, despite the adoption of the full range of engineering and technical safeguards, because people failed to do what they were supposed to do. These were not simple, individual errors, but malpractices that corrupted large parts of the social system that makes organizations function. ... Safety experts now estimate that 80-90% of all industrial accidents are attributable to 'human factors'. It is now widely accepted that the most effective way to reduce accident rates is to address the social and organizational factors.“ -- Mark Fleming and Ronny Lardner 8 Definition of TSM Culture 9 A TSM culture is the everyday manifestation of a deeply ingrained set of values that makes continually improving the work environment one of the organization’s highest priorities. It shows up in procedures, expectations (performance), habits and traditions that promote safety, health, and competitiveness. (Page 40) Goetsch, D.L. 1998, 'Establish a TSM culture', in Implementing Total Safety Management: Safety, Health, and Competitiveness in the Global Marketplace Establish a TSM Culture 10 TSM cultural characteristics (P217) Identifying and removing organizational roadblocks (P218) Turn key people into advocate Gaining a commitment to safety (P51) Historical path from safety engineering to culture change CC E3 E3 E1 E1 (E1) Engineering E1 E2 E2 (E2) Education E1 E3 BB E1 E2 (E2) Enforcement 11 (BB) Behaviour-based BB E2 (CC) Culture Change Advice from Behaviorists E. Scott Geller. . . “The Psychology of Safety” “The intent must not be to control people, but to help them control their own behavior for the safety of themselves and others. This is why the terms such as behavior modification, discipline and enforcement are inappropriate. They carry the connotation of outside control. The bottom line is that behavior is motivated by consequences that are obvious and immediate” 12 Behavior-Based Safety vs Hierarchy of Control of Hazards Behavior-Based Safety 1. The belief that worker behavior is the precursor to safety or injury 2. Implementation must be achieved through training (lots!) 3. High participation is critical for success 4. Management commitment to the process is essential 5. Behavior is objective and can be observed 6. Unsafe or at-risk behavior can be objectively measured 7. Improving safe behavior and minimizing at-risk behaviors reduces injuries 13 Hierarchy of Health & Safety Controls 1. Elimination or substitution 2. Engineering controls 3. Warnings 4. Training and Procedures/Administrative controls 5. Personal Protective Equipment National Safety Council & UAW Paper on “A Union Critique of Behavior Safety 14 Employees Complaints about Behavior-Based safety 15 Ignores hierarchy of risk controls Not a risk management approach Puts responsibility of worker Creates climate of fear Rules based approach only Takes employer and regulator off the hook Research based on false and questionable logic Health & Safety Process Model Identification Evaluation Control Data Analysis Claims assessment Surveys & Questionnaires Risk Assessment Hazard Analysis Select Controls based on Hierarchy Interviews Worker Complaints Government Regulations Inspections/Audits UAW Safety Model 16 Assignment 1 (a) How easy is it to establish a positive safety culture in an organization which has ineffective, mediocre or a negative safety culture? Hints: Find out from p. 32, 33 and 217 and the article of Barraclough & Carnino about the characteristics of a positive safety culture. Based on the findings, comments on the how difficult is it to achieve the performance characterized by those features of a positive safety culture. 17 Assignment 1 (b) In your opinion, how can a poor safety culture be changed, or how can an effective, proactive safety culture be improved? Hints: Read Page 33-35 Understand the “Culture Iceberg” concept illustrated on Page 34. Use GOOGLE to conduct a search on “Cultural Change” and “Management of Change” Summarize what Action Strategies could be adopted. Comments on their limitations and implications 18 Actionable Model Theories of Actions Chris Argris & Donald Schön 19 Assignment 1 (c) Which are the safety management tools and practices that can introduce effective safety culture, or change a negative safety culture? Hints Understand the safety management concepts Make reference to the “TOOLKITS” Webpage at URL: http://www.ic.polyu.edu.hk/safety/toolkits/index.htm Search and select SM tools and good practices that can be put into practice 20 What Characterizes a Good Safety Management System? 21 Discuss in groups Summarize and present the results of discussion by a group representative Case Study An integrated SMS of an airport (http://icnet.polyu.edu.hk/d3/airport/final%20report/finalreport-presentation.ppt) 22 The External Environment Integrated Performance-based Safety Management System •Stakeholders •Regulating Agencies/units Continuous Improvement Integration Safety Management Review Safety Management System Safety Management Structure Evaluation of Performance Initiation (OSH inputs) Communication Audit / Review Corporate Safety Management [reference Recommendation No. 3(b)] Management Commitment and Resources Safety Policy, Goals & Objectives Safety Section OSH Advisor Overall Planning and Performance Monitoring OSH Process Formulation OSH Policy Goals & Objectives Performance Standards Overall Safety Planning Manual & Guidelines [to be prepared by Line Departments] Line Departments Employee Participation L1 L2 L3 Contractors Contractors Contractors 23 Implementation / Operations OSH Training Risk Management Programs Operational Safety Procedures Prevent / Correct Actions Procurement / Contractors Emergency preparedness •Meeting OSH Goals & Objectives •Accident & Injury Rates •Changes in Efficiency •Overall Safety Performance [to be prepared by Line Departments] Safety Performance (Outputs)