GMP Training

advertisement

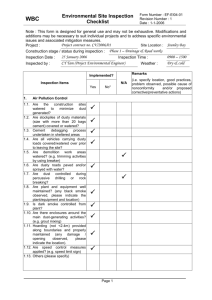

Avoiding Noncompliance Lori F. Hirsch Managing Counsel July 10, 2013 a a • Our vision is to make a difference in the lives of people globally through our innovative medicines, vaccines, biologic therapies, consumer health, and animal products – >70 manufacturing sites in our internal network. – Also utilize external manufacturing sites to manufacture APIs, finished product and packaging. 2 Some General Statistics • More than 100 Regulatory inspections annually of Merck Manufacturing sites covering: – – – – – Pharmaceuticals Vaccines Biologic Therapies Consumer Health Products Animal Health Products Including, without limitiation, FDA, EMA, MHRA, PMDA, TGA, Health Canada and WHO • As required, file Field Alert Reports • As required, file Biologic Product Deviation Reports 3 Working at a Pharmaceutical Company as In-house GMP Counsel! 4 Typical Work of In-house GMP Counsel • • • • • • • • • Member of the Global Quality Leadership Team Member of the Manufacturing Division Compliance Committee Review of Regulatory Responses to 483s and other Regulatory Agencies’ inspection observations Member of Fact Finding/Recall Committee Review of Regulatory notifications to ensure compliance with the regulations, including Field Alert Reports and Biologic Product Deviation Reports Review of Quality Agreements with third parties Serve as internal consultant on interpreting cGMPs Perform Regulatory surveillance, such as reviewing Warning Letters, Regulatory actions, etc, for applicability. Work with outside counsel on an as needed basis 5 The Role of In-house GMP Counsel • • • • • • Help clients understand the “c” in cGMPs. Know the business – become an expert not only in the law but in the manufacturing and testing processes as well as the Quality Systems. – The more you know about the processes, the more effective you are as a lawyer and the more credible you are with the clients. Help ensure that the right people, processes and systems are in place to ensure compliance. If an issue arises, – Ensure the use of critical logic (including Risk Based Methodology) – Help sites drive to root cause – Ensure that there are both preventative and corrective actions which are sustainable. • Has the issue been addressed holistically? Consider not only tactical fixes but systemic actions needed Partner and Communicate with your clients, early and often! 6 7 What is needed to ensure compliance? Permanent Inspection Readiness Strong Systems Good Processes Right People Strong Compliance Culture 8 Quality Culture • • • • • Every person is a Quality Leader! “Safe to speak up” environment. Make problems visible and solve them once. Bottom Up rather than Top Down Quality Institutionalization of a culture/attitude in which all employees, regardless of level or function, have ownership and accountability for Quality and Compliance. 9 Right people • Must have the right people in the right jobs. – – – – Do they have the skills to be successful? Do they have the appropriate background? Are they trained? Are people accountable for their actions? 10 Processes • Must have appropriate processes – – – – – – Are your processes written? Are your processes well understood? Are personnel adequately trained in the processes? Can your employees explain them in their own words? Are the processes repeatable and robust? Do they lend themselves to Right First Time? 11 Systems • Robust systems and Quality oversight must be in place to ensure long-term success and sustainability. – Do you have a system in place to find, detect and correct any issues? – Do you have an effective and comprehensive audit program (at sites as well as divisionly)? – Do you have an effective and comprehensive CAPA system? – Do you have appropriate checks and balances built into your system. 12 Permanent Inspection Readiness Permanent Inspection Readiness Strong Systems Good Processes Right People Strong Compliance Culture Key Takeaways: 1. Issues will happen, but what distinguishes a company is how quickly and comprehensively it reacts to those issues. 2. A company must have a culture that learns from mistakes, and takes steps to correct an issue and prevent it from recurring. 13 What will be the result of your next inspection? 14 What Can You Expect During an Inspection..… • • • • Document requests – Annual Reviews, Investigation and Change Request Lists, BPDRs/Field Alerts, Sterility Investigations, Environmental Monitoring Results, Customer Complaints. – Detailed review of deviations and corresponding investigations and CAPAs. Tours of Processing Areas Interviews with personnel at all levels of the organization (operators through senior managers) – Emphasis on bottom-up vs. top-down approach to problem solving. – Consistent information must be presented. Review of corrective actions from previous inspection – Verify implementation was done as committed. – Data/information to show that actions have prevented recurrence. 15 What Investigators Will Expect – Well maintained/well kept facilities - first impressions matter! – Employees know SOPs and core responsibilities, and can explain them – Personnel Adhere to GMPs & Procedures – Strong Quality Systems are in place – CAPAs are implemented and measured to ensure effectiveness (problems are solved once) – Site has self awareness of problems & shortcomings – Quality Culture is engrained and part of the fabric of the site. – Documentation of planned future actions (“intentions”) • E.g., Project Plans, CAPAs, etc. 16 Inspection Musts Ensure that the RIGHT PEOPLE discuss the RIGHT INFORMATION at the RIGHT TIME in the RIGHT WAY! 17 What Investigators Will Not Tolerate • Delays in retrieving documents or the need to request documents repeatedly • Incomplete documentation • Inaccurate information • Interviewees who do not respond to the questions asked. • Being given different answers to the same question. • Lack of knowledge • Lack of transparency 18 Key Points to Remember A good inspection outcome is a function of: – Training, Competence, Preparation and Confidence of Personnel – Detailed knowledge of past commitment actions and status – Knowledge of current inspection trends – Effective documentation and clarity – Effective interactions and communications with Inspectors 19 Responding to Inspection Observations • Respond within the 15 working day period. • Responses are the Company’s opportunity to demonstrate that the Company has corrected or will correct any deficiencies and that appropriate systems exist to prevent recurrence. • Ensure that the responses are well-written, factually correct and complete, logical and explains the corrective and preventative actions to be taken – Responses should respond to the specific observations as well as describe systemic actions, as appropriate. – Site is responsible for the responses and commitments. 20 How will your manufacturing site be rated after the inspection? 21 Avoiding a Crisis problems detected scrutiny from more players more problems detected problems not addressed increased scrutiny/ publicity 22 22 Common elements of failure • • • • • Inadequate follow-up Repeat violations (e.g., ineffective CAPAs) Local not system wide corrections Failures to find, detect and correct Corporate Culture Issues – – – – Ineffectiveness of Quality organization Lack of checks and balances Management Failures Complacency/Arrogance 23 Quality Lessons • Deficiencies occur/ mistakes happen • Key is to have systems in place that – Provide for strict accountability/ checks and balances – Investigate root causes – Assure complete and systemic correction – Document and validate changes • Ensure truthfulness in all responses • Live up to all commitments made to an Agency. • Apply “Lessons Learned” across the organization. 24 Questions? 25