The Quality Improvement

Journey: From TQM to QI

HIVQUAL Workshop

June 24, 2011

Dan Belanger Terry Hamilton Lawrence Hansley

1

Agenda

Welcome and Introductions

SWOT Analysis Small Group Exercise

Total Quality Management

Key Tools and Techniques

Origins of Quality Management

Histogram Small Group Exercise

Continuous Improvement

6 Sigma

Lean

Lean Small Group Exercise

The Model for Improvement

2

Ice Breaker: SWOT Analysis

Small Group Exercise

Your HIV QM Committee is considering

adding consumers to the HIV QM

Committee

To understand the pros and cons you

decide to do a SWOT Analysis (strengths,

weaknesses, opportunities and threats)

Using the worksheet in your packet, each

group brainstorms a SWOT analysis and

reports back

3

Quality Roots

The roots of Total Quality Management

can be traced to early 1920's

production quality control ideas, and

concepts developed in Japan

beginning in the late 1940's and

1950's, pioneered there by Americans

Feigenbaum, Juran and Deming

4

Total Quality Management (TQM)

Total Quality Management features:

the customer-supplier interfaces, (external and

internal customers and suppliers)

an organizational commitment to quality

the importance of communicating this quality

commitment

the acknowledgement that the right

organizational culture is essential for effective

Total Quality Management

5

Tools and Techniques

An array of tools and techniques is used for

identifying, measuring, prioritizing and

improving processes critical to quality

6

Process Improvement Tools

These process improvement tools and

techniques include:

PDSA (plan, do, study, act) Cycle

Flow-charting

Cause and effect diagram,

Brainstorming

Pareto Analysis

7

The PDSA cycle

for learning and improvement

Act Plan

Objective

What changes Questions and

are to be made? predictions (why)

Next cycle? Plan to carry out the cycle

(who, what, where, when)

Study

Complete the

analysis of the data

Compare data to

predictions

Summarize what

was learned

Do

Carry out the plan

Document problems

and unexpected

observations

Begin analysis of

the data

8

Flow Charts

Purpose: Graphic depiction of how a

process works

Use: 1) visualize and understand a

process;

2) consider ways to simplify;

3) recognize unnecessary steps;

4) identify who will be involved in or

effected by improvement process

Caution: 1) flowchart must reflect

real process;

2) people who know the process

must be involved;

3) be sure the flowchart focuses on

the identified problem

Commonly Used Flow Chart Symbols:

Terminator

Task or Step

Decision

Wait symbol

9

Flow Chart Example

Client Arrives at Drop-In Center

Patient arrives at front desk

Front Desk Staff Asks Client for Name

& Searches Database

Client in system?

YES

NO

Receptionist asks client

to complete paperwork for new clients

and return it to front desk

Ask client to be seated in the

Waiting room

ETC.

HR Counselor

takes client into

Counseling Room

10

CAUSE-AND-EFFECT DIAGRAM

SAMPLE

Skeleton

Equipment

Environment

Computer

System down

for routine

maintenance

Low show rate

for appointments

Patients

Procedures

People

Patient unaware

of appointment

11

Brainstorming

Purpose: To provide a freewheeling

environment in which everyone is

encouraged to participate.

Use:

generate new ideas/insights

draw out experiences of each

participant

when creative ideas have been

suppressed by group

Caution:

ideas will need elaboration

discussion impedes & limits flow of

ideas

12

Feigenbum, Juran and Deming

Quality Management resulted mainly from the

work and theories of Americans who took the

messages of quality to Japan in the 1950's:

Joseph Juran

W Edwards Deming

Armand Feigenbaum

13

W Edwards Deming

placed great importance and

responsibility on management, at both the

individual and company level, believing

management to be responsible for 94% of

quality problems.

14

Deming’s

14 Point Management Plan

Create constancy of purpose towards

improvement of product and service

Adopt the new philosophy. We can no longer

live with commonly accepted levels of delay,

mistakes and defective workmanship

Cease dependence on mass inspection.

Instead, require statistical evidence that

quality is built in

End the practice of awarding business on the

basis of price

15

Deming’s 14 Point Plan Continued

Find problems. It is management’s job to

work continually on the system

Institute modern methods of training on the

job

Institute modern methods of supervision of

production workers, The responsibility of

foremen must be changed from numbers to

quality

16

Deming’s 14 Point Continued

Drive out fear, so that everyone may work

effectively for the company

Break down barriers between departments

Eliminate numerical goals, posters and

slogans for the workforce asking for new

levels of productivity without providing

methods

17

Deming’s 14 Point Continued

Eliminate work standards that prescribe

numerical quotas

Remove barriers that stand between the

hourly worker and their right to pride of

workmanship

Institute a vigorous program of education and

retraining

Create a structure in top management that

will push on the above points every day

18

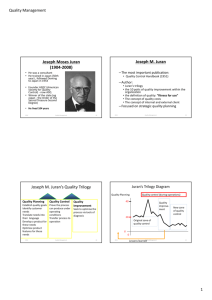

Dr Joseph M Juran

developed the quality trilogy – quality planning,

quality improvement and quality control.

Good quality management requires quality actions

to be planned out, improved and

controlled.

The process achieves control at one level of quality

performance, then plans are made to improve the

performance on a project by project basis, using

tools and techniques such as Pareto analysis.

This activity eventually achieves breakthrough to an

improved level, which is again controlled to prevent

any deterioration.

19

Pareto Chart

Purpose

Compare the various factors that contribute to an

overall effect.

Indentify the “vital few” (factors that, warrant the

most attention) from the “useful many” (factors that,

while useful to know about, have relatively smaller

effect).

Based on the Pareto Principle which suggests that

most effects are the result of relatively few causes,

that is, approximately 80% of effects come from 20%

of potential causes.

Analyzing Data

20

Analyzing Data

21

Juran

Juran believed quality is associated with

customer satisfaction and dissatisfaction with

the product

emphasized the necessity for ongoing quality

improvement through a succession of small

improvements

projects carried out throughout the

organization.

22

Juran’s 10 Points to QI

Build awareness of the need and opportunity

for improvement

Set goals for improvement

Organize to reach the goals

Provide training

Carry out projects to solve problems

23

Juran’s 10 Points to QI Continued

Report progress

Give recognition

Communicate results

Keep score of improvements achieved

Maintain momentum

24

Armand V Feigenbaum

Feigenbaum was the originator of “total

quality control”, often referred to as total

quality.

25

Feigenbaum’s Definition of Total

Quality Control

“An effective system for integrating quality

development, quality maintenance and

quality improvement efforts of the various

groups within an organization, so as to

enable production and service at the most

economical levels that allow full customer

satisfaction”.

26

Feigenbaum’s 3 Steps to Quality:

Quality leadership

Modern quality technology

Organizational commitment

27

Late 1950’s Japanese who developed new concepts in

response to the Americans

Dr Kaoru Ishikawa

Shigeo Shingo

Dr Genichi Taguchi

28

Ishikawa’s 7 Basic Tools of Quality

Pareto analysis which are the big problems?

Cause and effect diagrams what causes the

problems?

Stratification how is the data made up?

Check sheets how often it occurs or is done?

Histograms what do overall variations look like?

Scatter charts what are the relationships between

factors?

Process control charts which variations to control

and how?

29

Cause-and-Effect Diagram

Organizes and displays all causes and sub-causes that

may influence a problem, outcome, or effect

Helps push people to think beyond the obvious causes,

(money, time) to find some causes that they can

fix/improve

Helps organize potential solutions and make clear who

should be involved in solutions

Encourages a balanced view

Demonstrates complexity of the problem

30

Cause and Effect Diagram of

HIV-infected Homeless Youth

Not Receiving HIV Primary Care

Individual factors

Individual factors

Individual factors

Poor Resources

History of physical/emotional/

sexual abuse

Sexual

minority

Survival sex

Low educational

attainment

Unstable

Housing

Drug/Alcohol abuse

Family conflict/neglect/

abandomnment

Low

Self-efficacy

Poor condom use

Foster care system

Mental health

disorder

Poor condom use

Poor access to

resources

Incarceration

Stigma

Laws

Violence

Discrimination

Policies

Economics

Poor access to resources

Social factors

Social Factors

31

31

Histograms

Purpose

Used to display the variation in continuous data

like time, weight, size or temperature

Helps teams recognize and analyze patterns in

data that are not apparent simply by looking at a

table of data, or by finding the average or median

32

What’s our Pattern Here?

Group Discussion

(10 Minutes)

Number of days for follow-up GYN appointment

Source: Institute for Healthcare Improvement

Analyzing & Displaying Data

33

Shigeo Shingo

Associated with Just-in-Time manufacturing,

The Use of a checklist- humans can forget or make

mistakes

the inventor of

the single minute exchange of die (SMED) system, in

which set up times are reduced from hours to minutest

Poka-Yoke (mistake proofing) system. In Poka Yoke,

defects are examined, the production system stopped and

immediate feedback given so that the root causes of the

problem may be identified and prevented from occurring

again.

34

The Mistake Proofing System

Shingo distinguished between “errors”, which

are inevitable, and “defects”, which result

when an error reaches a customer

the aim of Poka-Yoke is to stop errors from

becoming defects.

Defects arise because errors are made and

there is a cause and effect relationship

between the two.

35

Dr Genichi Taguchi

believed it is preferable to design

product that is robust or insensitive to

variation in the manufacturing process, rather

than attempt to control variations during

actual manufacture

36

Taguchi’s 3 Quality Stages

System design

Parameter design

Tolerance design

37

Kaizen or Continuous Improvement

The aims of a Kaizen organization are

typically defined as:

To be profitable, stable, sustainable and

innovative.

To eliminate waste of time, money, materials,

resources and effort and increase productivity.

To make incremental improvements to systems,

processes and activities before problems arise

rather than correcting them after the event.

To create a harmonious and dynamic organization

where every employee participates and is valued.

38

Key concepts of Kaizen

Everyone involved in a process or activity,

however apparently insignificant, has

valuable knowledge and participates in a

working team or Kaizen group

Everyone is expected to participate,

analyzing, providing feedback and suggesting

improvements to their area of work.

39

Key concepts of Kaizen continued

Every is a key word in Kaizen: improving

everything that everyone does in every

aspect of the organization in every

department, every minute of every day.

Evolution rather than revolution: continually

making small, 1% improvements to 100

things is more effective, less disruptive and

more sustainable than improving one thing by

100% when the need becomes unavoidable.

40

Key concepts of Kaizen

Every employee is empowered to participate

fully in the improvement process: taking

responsibility, checking and co-coordinating

their own activities. Management practice

enables and facilitates this.

Every employee is involved in the running of

the company, and is trained and informed

about the company. This encourages

commitment and interest, leading to

fulfillment and job satisfaction.

41

The Quality Circle

The idea of the quality circle was first

introduced by Japanese business as a

way to involve all employees in their

organization’s quality program.

42

Quality Circles

A quality circle is a group of 3 to 12 coworkers who agree on a volunteer basis to

meet together regularly to identify and

analyze problems and to brainstorm solutions

Solutions are presented to management

Quality Circle participants in some cases may

implement solutions

43

1970’s-1980’s Western Gurus:

Philip B Crosby

Known for the concepts of

“Quality is Free”

“Zero Defects”,

4 Absolutes of Quality

44

Crosby’s 4 Absolutes of Quality

Quality is conformance to requirements

The system of quality is prevention

The performance standard is zero defect

The measurement of quality is the price of

non-conformance

45

Tom Peters

identified leadership as being central to

the quality improvement process, discarding

the word

“Management” for “Leadership”.

The new role is of facilitator, and the basis is

“Managing by walking about” (MBWA),

enabling the leader to keep in touch with

customers, innovation and people, the three

main areas in the pursuit of excellence.

46

Tom Peters

believes that, as the effective leader

walks, at least 3 major activities

are happening:

Listening suggests caring

Teaching values are transmitted

Facilitating able to give on-the-spot help

47

Framework for Measuring Healthcare

Quality

In 1966 Avedis Donabedian developed the

first conceptual framework to measure the

quality of healthcare

Measure quality by assessing structures,

processes, outcomes of care

48

National Health Service (UK)

NHS Improvement has over 10 years

improvement experience

Use practical knowledge and “how to”

approach to help improve the quality and

productivity of services

Use innovative approaches as well proven

improvement methodology.

Integrates sociological concepts into

improvement work

49

Six Sigma

Since the 1920's the word 'sigma' has been

used by mathematicians and engineers as a

symbol for a unit of measurement in

product quality variation

3.4 parts - or defects - per million

In the mid-1980's engineers in Motorola Inc

in the USA used 'Six Sigma' as a name for

an in-house initiative for reducing defects

in production processes

50

Motorola

In the late-1980's following the success of

the above initiative, Motorola extended the

Six Sigma methods to its critical business

processes

in-house 'branded' name for a performance

improvement methodology

51

Motorola’s Definition of Six Sigma

"...Six Sigma has evolved over the last two decades

and so has its definition. Six Sigma has literal,

conceptual, and practical definitions. At Motorola

University (Motorola's Six Sigma training and

consultancy division), we think about Six Sigma at

three different levels:

As a metric

As a methodology

As a management system

Essentially, Six Sigma is all three at the same time."

52

Six Sigma Methodology

Understanding and managing customer

requirements

Aligning key business processes to achieve

those requirements

Utilizing rigorous data analysis to minimize

variation in those processes

Driving rapid and sustainable improvement to

business processes.."

53

Six Sigma Leaders and Teams

Six Sigma team leaders (Black Belts) work

with their teams (team members will normally

be people trained up to 'Green Belt'

accreditation) to analyze and measure the

performance of the identified critical

processes.

54

the DMAIC model for process

improvement.

DMAIC is commonly used by Six Sigma project

teams and is an acronym for:

Define opportunity

Measure performance

Analyze opportunity

Improve performance

Control performance.."

55

DMAICT process elements

D - Define opportunity

M - Measure performance

A - Analyze opportunity

I - Improve performance

C - Control performance, and optionally:

T - Transfer best practice (to spread the

learning to other areas of the organization)

56

HHCs Past

HHC examples…

Chronic Care Collaboratives

Ambulatory Care Redesign

1,000,000 Lives Campaign

57

BREAKTHROUGHHHCs Improvement System

History of Lean

Kaizen

Driven by metrics to right

size

Staff teams

Value=

What the customer wants

58

Rapid Improvement Event- (R.I.E.)

Hallmarks

Planned, team-based event

Fresh-eyes and pros

1 wk, intensive, facilitated

Specific follow-up to sustain

59

Breakthrough- Impact at HHC

From

start to now, ~$150 million

in revenue or decreased

expenses

≥ 8,800 employees have

participated

~700 R.I.E.s

60

TOOLS We Know

Pick Chart

Pareto Chart

Root Cause Analysis

PDSA

Brainstorming

61

A3

STORY

9

Paper and pencil!

boxes

Eliminate MUDA or Waste

62

A3 Boxes

1

Reason for Action

succinct problem statement,

burning platform

2

Initial State

where you are now

3

Target State

where you want to be

4

Gap

Analysis

difference between boxes 3

and 4

5

Solution approach

ideas/ways for closing the

gaps

6

Rapid Experiments

tests of the Solution

Approaches

7

Completion Plan

what is left to do after the RIE

week

8

Confirmed State

how achievement of Target

State is measured

9

INSIGHTS

63

8 Wastes

1.

2.

3.

4.

5.

6.

7.

8.

Over Production

Waiting

Transport

Extra Processing

Inventory

Motion

Defects

Unused Human Potential

64

6S

Sort

Straighten

Scrub

Safety

Standardize

Sustain

65

5 Why’s

Why?

Why?

Why?

Why?

Why?

Determines Root Cause

66

Just Do It

Type of improvement activity.

Solution is known.

Does not require R.I.E.

Put in place with limited resources

67

Exercise 1

Increase clinician participation in monthly QI

meeting by 10%

1

Reason for Action

Increase clinician

participation in monthly

QI meeting

2

Initial State

3

Target State

4

Gap

Analysis

5

Solution approach

6

Rapid Experiments

7

Completion Plan

8

Confirmed State

9

INSIGHTS

68

PICK ChartDo the High Benefit / Low Difficulty actions now

! Identify Actions then and

group into

P

BENEFIT

DIFFICULTY

6

Possible

High Benefit, Easy to Do.

Implement Now

C

9

7

Impac

t

Implement

1

2

High benefit, Make a plan how to do

it.

I

4

Challenge

I P

C K

Low benefit, but easy to do

K

Kick Out

5

3

8

Low benefit and difficult to do.

Kick it out !

Difficulty

69

Exercise II

Pick Chart

a.

Increase by 15% the number of

MSM who have at least 4 kept

medical appointments during the

year.

b. Engage 3 consumers 2x each

month in QI planning activities.

70

Summary

QI

is a strategy

Many tools

Many opportunities

Just Do It!

71

Model for Improvement

Developed by Associates in Process

improvement

Simple elegant

Captures the central concepts and core

principles of Quality improvement in a clear,

concise fashion

72

Model for Improvement

What are we trying

to accomplish?

How will we know that a

change is an improvement?

What change can we make that

will result in improvement?

Act

Plan

Study

Do

Model

for

Improvement

73

Conclusion

The same basic principles guide Quality

Improvement and Quality Management

Methodologies

The specific methodology used is not as

important as the commitment to quality

improvement principles, taking action and

improving the quality of care

74

Resources

Bruce Agins,MD

Clemens Steinbock

Kevin Garrett

Alan Chapman 2004-2009

Institute for Healthcare Improvement

The Economist Newspaper Copyright 2011

Associates in Process Improvement

www.Businessballs.com

National Health Service, www.improvement.nhs.uk

Copyright 1994-2005 Motorola, Inc.

Toyota Production Systems

Mark R. Chassin and Jerod M. Loeb, The Ongoing Quality

Improvement Journey: Next Stop, High Reliability Health Affairs on

April 25, 2011

75

Further Reading

Beckford, J., “Quality: A Critical Introduction”, Routledge,

London, 1998; 4th edn, 2002

Crosby, P., “Quality is Free: The Art of Making Quality

Certain”, McGraw-Hill, 1979

Ishikawa, K., “What is Total Quality Control?

The Japanese Way”, Prentice Hall, 1985

Juran, J., “Juran on Planning for Quality”, Free Press, New

York, and Collier Macmillan, London, 1988

76

Special Thanks to…

Terry Hamilton

Lawrence Hansley

HHC

77

And…

Thank you!!!!

78