ISO13053-1-introduct..

advertisement

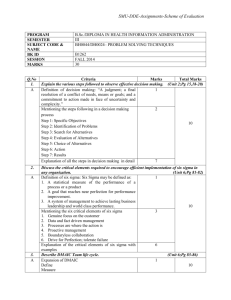

ISO 13053-1:2011 An introduction 4th October 2012 for Lean Six Sigma Ireland members Bernie Rushe BSc, CPIM, Dip SA, MSc brushe@cordatus.ie 087-2837810 2 ISO 13053-1:2011 Document content 1 2 3 4 Introduction 8 Training Symbols & terms 11 Tools Fundamentals of 6 Sigma Projects 12 Monitoring a project Quantitative methods in process improvement Scope 9 Project prioritization — Six Sigma Part 1: DMAIC 10 methodology Normative references DMAIC methodology (€106 restricted to one copy download) Note: ISO 13053-2:2011 5 Six sigma measures 13 Critical success factors Quantitative methods in process improvement — Six Sigma Part 2: Tools &14 Techniques 6 Six sigma personnel Infrastructure 7 3 is not reviewed Competencies (€127 restricted to one copy download) Annexes: Scores & training Scope of ISO document The improvement of existing processes • • • DMAIC project management Roles & expertise Training DFSS Certification Other project management methods 4 Maturity Model - Processes D M 5 A I C Roles & Population Density Steering cmttee Depl Deploymnt MBB mgr Mgr Org size Master BB 250 – 1,000 GB YB 1:30 emp all Sponsor Sponsor <250 emp BB Champion 0 0 Master BB 1 PT 1:5 BB 1:5 GB 1:5 GB Master BB 1:30 All roles are all emp in defined ISO >1,000 emp 6 1 FT 1:5 BB 1:5 GB 1:30 emp all Course Duration SponMBB sor Category Depl Mgr Instruction (days) 3 1 Tutorials - - (days) # qualifying projects - - BB GB YB 10 20 5 1 2 5 1 0 2 2 Workshop, eLearning or distance learning Competency table by role 7 1 0 Typical GB training agenda Day 1 Define Day 2 5 days Measure Day 3 Analyse Day 4 Improve Improvement Concept of Capability Assessment: Alternative idea variation analysis generation Written or multiple choice exam 1 six sigma “Should be” DMAIC FMEA projectPareto analysis process map methodology Oral examination Box plots Identifying CTQCs Types of data Conducting an Project selection Process mapping Data collection plans Refining project MSA scope Histograms Cause and effect matrices Run charts FMEA Pilot improvements Validate improvements Assessment by BB Scatter plots Internal or external accreditation Similar to Motorola model Cause and effect diagrams ASQ – broader curriculum, no project Waste and value analysis 8 Day 5 Control Error proofing Long-term MSA plan p charts u charts X and R charts X and R moving charts SOP's and training plans BB Training – typical week 1 (of 4) 20 days Week 1 (Define) Day of poor quality models; business measures; Day 1 CostGB Assumes training completed benchmarking; project financials Assessment: of waste; concept of value; Day 2 Identification Written or multiple choice exam opportunities; Six Sigma measures; project selection 2 six sigma projects Oral Problem definition; identifying customers; process Day 3 examination mapping; characteristic selection matrices; Assessment bycause MBBand effect diagrams Internal orbuilding; externalpersonality accreditation Team style profiling; project Day 4 charter; project management; Gantt charts Similar to Motorola model ASQ – 1 project only with 3 years experience, GB not necessary 9 Discussion Points Process mapping not mentioned as a source of six sigma projects BB & GB training content: Motorola vs ASQ Full time vs part time roles not addressed YB – no assessment or certification Impact on ASQ certification 10 Additional slides 11 Six Sigma1 Purpose Project based Improved business and quality performance Improved profit by addressing serious business issues that may have existed for a long time. Difference? Business case Structure 12 1 Motorola registered trade mark Six Sigma Project Question Solve a given problem Six Sigma phase Contribute an organization's business goals What is thetoissue? Define Undertaken only when the solution to a problem is not known Where is the process now? Measure “Voice of the customer” - a permanent feedback loop Accounting model - financial performance is evaluated What is causing this? Analyse Also take into consideration safety & customer satisfaction Performance the project reviewed regularly with What can be of done about-it? Improve sponsor How can it be kept there? 13 Control Measures defined DPMO Sigma Z score 1.5 Sigma shift RTY RR NPR OTD COPQ 14 Standard deviation is not defined Project selection, priority & DMAIC Difficulty vs Profit Prioritization matrix 15 Question Six Sigma phase What is the issue? Define Where is the process now? What is causing this? Measure What can be done about it? Improve How can it be kept there? Control Analyse Outputs from each phase Tools used Project management Success factor (Data driven …) Linked to an organization's business objective Associated with a KPI Linked to CTQ or CTC Project Sponsor is a senior member of the organization with sufficient influence The objective for the project will be to deliver a significant impact on the organization Project completed promptly and within its notional timescale Resourced to the required levels Has a process with clearly identifiable KPIVs and KPOVs Ready availability of reliable data 16