Chapter 1

advertisement

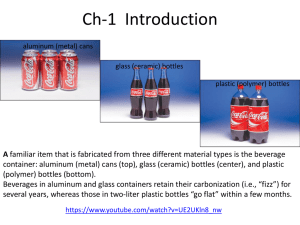

CHEN 313: Materials Science and Engineering Course Objective... Introduce fundamental concepts in Materials S&T You will learn about: • material structure • how structure dictates properties • how processing can change structure This course will help you to: • use materials properly • realize new design opportunities Class Notes adapted/prepared by Jorge Seminario (TAMU) Chapter 1- a Required text Fundamentals of Materials Science and Engineering: An Integrated Approach 3rd Edition W.D. Callister, Jr. and D. G. Rethwisch John Wiley and Sons, Inc. (2007). Both book and accompanying CDROM are useful. Chapter 1- GRADING Homework, quizzes, (INDIVIDUAL) 15% Special assignments (GROUPS) 10% exam # 1 15% exam #2 15% exam #3 15% final 30% Chapter 1- g Special Assignment 1) Check 2010-2011 Issues of Nature & Science; find the best topic you like 2) Propose and justify a topic February 7 3) Instructor will decide topics on Feb 11 4) First Draft due on February 28 5) Second Draft due on March 21 6) Final version due on April 22 Chapter 1- 1.1 Historical Perspective • Early Civilivations – Bronze Age, Iron Age, Stone Age – Materials were naturally occuring Chapter 1- Historical Perspective (Cont’d) • Modern Era – Understand structure and properties – New materials have evolved • Ex. Plastics, Glasses, Fibers Chapter 1- 1.2 Materials Science and Engineering • Structure – Atomistic – Atoms, small molecules ~ 1 Å – Nanoscopic – molecules, clusters, ~1 nm – Microscopic – Large groups of atoms agglomerated – Macroscopic – can be viewed by the “naked eye” Chapter 1- Materials Science and Engineering Property Example (Physics) Example Properties Mechanical Rate of material deformation to an applied load Elastic modulus Electrical Response of material to an applied electrical field Electrical conductivity Thermal Material expansion/contraction with change in temperature Heat capacity, thermal conductivity Magnetic Response of a material to an applied magnetic field Magnetic susceptibility Optical Response of material to electromagnetic radiation Refractive index Deteriorative/ Chemical Rate of decomposition of material (often in presence of acid, etc.) Corrosion rate Chapter 1- 1.3 Why do we study materials? • Many engineering fields deal with a design problem involving materials sooner or later • For example: transmission gears, superstructure of a building, oil refinery component, electronics, medicine, etc. • However, the problem is selecting the right material from the thousands out there. Chapter 1- Material criteria • Many selecting criteria affect final decision: – In-service conditions – Deterioration – Finished product cost Chapter 1- In-service conditions • dictates the material required properties • Rarely a material possess the maximum or ideal combination of properties • Sacrificing one characteristic for another might be necessary • i.e., strength vs. ductility: the stronger a material the less ductile (malleable) Chapter 1- Deterioration • Can occur during service operation • Mechanical strength might be lowered by: 1. Exposure to elevated temperatures 2. Exposure to corrosive environments Chapter 1http://majarimagazine.com/2009/01/corrosion-in-material-of-construction/ Finished product cost • You could have perfect material, but too costly • Again, some compromise or sacrifice must be made • Cost of finished piece includes fabrication cost Chapter 1- Materials Criteria • As an engineer, must familiarize yourself with these criteria • Also be comfortable with processing techniques • In conclusion, the more proficient, the more confident you will be in making judgment based on these criteria Chapter 1- Chapter 1- Groups for the Special Assigment Name Al Dagher, Ameer Bond, Jervon Bowen, Scott Bowser, Daniel Costello, Matthew Drew, Matthew Graf, David Heitzman, Corey Huffman, Jacob Keller, Austin Largent, Jessica Mc Dowell, Michael Moore, Ryan Muko, Cristina Nelson, Randall G 1 1 1 2 2 2 3 3 3 4 4 4 5 5 5 Name G Paulo, Carla 6 Postolowski, Michael 6 Raja, Fatima Ahmed 6 Russell, Lindsay 7 Schaaf, Andrew 7 Seo, Jung Yeon 7 Smith, Dylan 8 Southwick, Edward 8 Stout, Andrew 8 Trull, Amber 9 Van Dyke, Robert 9 Van Laer, Maxime 9 Vu, John 10 Wilson, Katelyn 10 Zamora, Briana Chapter 1-10 1.4 – Classification of Materials Chapter 1- Three Basic Material Classes – Metals – Ceramics – Polymers – Classifications are based on: • Chemical Makeup • Atomic Structure – Additional Material Classes: • Composites • Advanced Materials Chapter 1- Metals • Composed primarily of metallic elements – – – – Possible nonmetallic species present Orderly atomic arrangement High density High mechanical strength • Very Stiff & Strong • High Ductility • High Fracture Resistance – High electrical & thermal conductivity – Typically magnetic Chapter 1- Ceramics • Compounds of metallic and nonmetallic elements – Commonly oxides, nitrides & carbides – Mechanical strength comparable to metals • High stiffness & strength • Extremely low ductility • High fracture susceptibility – Low electrical & thermal conductivity – Optically variant • May be transparent, translucent or opaque – Some ceramics may be magnetic Chapter 1- Ceramic membrane: Ultrafiltration Ceramic Membrane Elements Ceramic membrane filter is widely used for filtration in industrial areas of food , beverage, pharmaceutical, chemical, petrochemical and environment-protecting Chapter 1- Polymers • Organic plastic & rubber compounds – – – – Large molecular structures based on hydrocarbon chains Frequent presence of oxygen, nitrogen and silicon Low density Unique mechanical properties • Lower stiffness & strength compared to metals & ceramics • Extremely high ductility & pliability – High degree of chemical inertness • Unreactive in a large range of environments • May decompose at temperature – Low electrical and thermal conductivity – Nonmetallic Chapter 1- shape-memory polymer clinical applications Xu J , Song J PNAS 2010;107:7652-7657 Chapter 1- Composites • A material composed of materials from two or more classes – Engineered to achieve a combination of properties not present in one single material – Fiberglass is a classic example of a composite material • Glass fibers are embedded within an epoxy or polyester substrate • Glass fibers cause the material to be strong & stiff • Polymer base provides ductility & flexible – Carbon Fiber Reinforced Polymers (CFRP) are a second example of composite materials • Carbon fibers are embedded in a polymer base • Stronger & stiffer than fiberglass, but far more expensive Chapter 1- Relative Material Density Ranges Chapter 1- Relative Material Elastic Modulus Ranges Chapter 1- Relative Material Tensile Strength Ranges Chapter 1- Relative Material Electrical Conductivity Ranges Chapter 1- 1.5 Advanced Materials Advanced materials are typically utilized in high-tech applications and are typically traditional materials whose properties have been enhanced as well as newly developed, high performance materials. Advanced materials include: semiconductors, biomaterials, ‘materials of the future,’ which include materials used in lasers, integrated circuits, magnetic storage, LCD’s, and fiber optics. Chapter 1- Semiconductors • Semiconductors have electrical properties that are intermediate between the electrical conductors (metals and alloys) and insulators (ceramics and polymers). • The electrical characteristics of these materials are extremely sensitive to the presence of minute concentrations of impurity atoms which may be controlled over very small regions. • Semiconductors have made possible the advent of integrated circuitry that has revolutionized electronics and the computer industry. Chapter 1- Biomaterials • Biomaterials are employed in components implanted into the human body for replacement of diseased/damaged body parts • These materials must not produce toxic substances and must be compatible with body tissues. • Metals, ceramics, polymers, composites, and semiconductors may all be used as bio materials. Chapter 1- Smart Materials • Smart materials are new, stateof-the-art materials for new technologies. • The “smart” implies that these materials are able to sense changes in their environments and then respond to these changes in predetermined manners. • Components of a smart material include a type of sensor (that detects input) and an actuator (that performs a responsive and adaptive function). Chapter 1- Four common Smart Materials: • Shape-memory – metals that, after being deformed, revert back to their original shape with a temperature change. • Piezoelectric ceramics – expand and contract in response to applied electric fields. They also generate an electric field when deformed. •Magnetostrictive – similar to piezoelectric except for magnetic fields. •Electrorheological fluids – liquids that experience dramatic changes in viscosity upon application of electric fields. Magnetorheological fluids also exist. Chapter 1- Nanoengineered Materials • The ability to carefully arrange atoms from the bottom up allows for the opportunity to develop mechanical, electrical, magnetic, and other properties into materials that are otherwise not possible. • The ‘Nano’ prefix denotes that the dimensions of these entities is on the order of a nanometer, or 10-9 meters. • This is the inside of a carbon nanotube. Chapter 1- 1.6 Modern materials’ needs • Although nuclear energy is promising, reliance on materials will continue • From fuels, to containment structures, to facilities where radioactive waste is disposed • Transportation requires a lot of energy • Materials of high strength low density will reduce weight and enhance machine efficiency http://energymats.lboro.ac.uk/ Chapter 1- Modern materials’ needs • Economical sources of energy are in need • Materials will have significant role in this • i.e. solar cells = convert solar energy into electrical energy but materials are expensive • These must be replaced with high efficient, low cost materials http://www.solarnavigator.net/solar_panels.htm Chapter 1- Modern materials’ needs • Hydrogen fuel cell very feasible and attractive • Holds promise in the car industry as a power source • However, before this is made efficient, better materials must be engineered Chapter 1- Modern materials’ needs • Producing new materials is great, but must be observed carefully • New materials could be great, but the pollution or waste produced during process needs to be considered • Also, less pollution and spoilage due to less mining of raw materials. Chapter 1- Modern materials’ needs • Many materials used are from nonrenewable sources • i.e. oil and some metals • Materials are being depleted steadily which is cause for: – Need of discovery of additional reserves – Development of similar materials with less adverse environmental impact – Increase recycling efforts Chapter 1- Modern materials’ needs • Challenges still remain even though large technological advances have been made • For example, the development of even more sophisticated and specialized materials • Also the environmental impact of material production • In conclusion, development is only good if all factors are considered • Best judgment made based on factors Chapter 1- The Materials Selection Process 1. Pick Application Determine required Properties Properties: mechanical, electrical, thermal, magnetic, optical, deteriorative. 2. Properties Identify candidate Material(s) Material: structure, composition. 3. Material Identify required Processing Processing: changes structure and overall shape ex: casting, sintering, vapor deposition, doping forming, joining, annealing. Chapter 1- 3 SUMMARY Course Goals: • Use the right material for the job. • Understand the relation between properties, structure, and processing. • Recognize new design opportunities offered by materials selection. Chapter 1- 9