Materials - 國立東華大學公共行政學系

advertisement

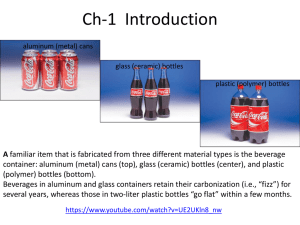

CHAPTER 1 Introduction to Materials Science & Engineering 國立東華大學 材料科學與工程學系簡介 • 民國八十六年成立碩士班 – 八十九年大學部 – 九十一年博士班 • 目前有十五名專任教授 • 研究生八十餘名及大學生二百餘名 天生我材必有用 MSE 101: Introduction to Materials Science & Engineering Course Objective... Introduce fundamental concepts in Materials Science You will learn about: • material structure • how structure dictates properties • how processing can change structure This course will help you to: • use materials properly • realize new design opportunities with materials 3 COURSE MATERIALS (with WileyPLUS) Required text: • WileyPLUS for Materials Science and Engineering: An Introduction, W.D. Callister, Jr. and D.G. Rethwisch, 9th edition, John Wiley and Sons, Inc. (2014). Website: https://www.wileyplus.com/WileyCDA/ •Homework assignments with instant feedback and hints • Computer graded self-help problems • Hotlinks in homework to supporting text section • Quizzes Online Open courses https://www.edx.org/ https://www.coursera.org/ 4 WEBSITES Course Website: • Syllabus • Lecture notes • Answer keys • Grades Text Website: http://www.wiley.com/college/callister • VMSE for 3D visualization and manipulation of atomic structures • Mechanical Engineering and Biomaterials online support modules • Case studies of materials usage • Extended learning objectives • Self-assessment exercises 5 Virtual Materials Science & Engineering (VMSE) Website: Student Companion Site • Users can manipulate molecules and crystals to better visualize atomic structures • Unit cells such as BCC, FCC, HCP • Crystallographic planes, directions, and defects • Polymer repeat units and molecules • Diffusion computations 6 GRADING Random in-lecture quizzes Midterm #1 30% Midterm #2 30% Home work 20% 10% Classroom performance 10% 7 Materials Science and Engineering Content 魏茂國 Historical perspective Materials science and engineering Why study materials science and engineering? Classification of materials Advanced materials Modern Materials needs Processing/structure/properties/performance 8 Materials Science and Engineering Introduction 魏茂國 A familiar item that is fabricated from three different material types is the beverage container. Beverages are marketed in aluminum (metal) cans, glass (ceramic) bottles, and plastic (polymer) bottles. Aluminum cans (metal) Glass bottles (ceramic) Plastic bottles (polymer) 9 Chapter 1 - Introduction • What is materials science? • Why should we know about it? • Materials drive our society – – – – Stone Age (2.5 million BC) Bronze Age (3500 BC) Iron Age (1000 BC) Now? • Silicon Age? • Polymer Age? • Carbon Age? 10 Materials Science and Engineering Historical Perspective 魏茂國 Materials are probably more deep-seated in our culture than most of us realize. Transportation, housing, clothing, communication, recreation, and food production-virtually every segment of our everyday lives is influenced to one degree or another by materials. Early civilizations have been designated by the level of their materials development (i.e., Stone Age, Bronze Age, Iron Age). The earliest humans had access to only a very limited number of materials, those that occur naturally: stone, wood, clay, skins, and so on. 11 Montage of Materials What are Materials? • the matter from which a thing is or can be made • may be defined as substance of which something is composed or made. • We obtain materials from earth crust and atmosphere. • Examples : Oxygen, Silicon, Alumium and Iron constitute 46.60, 27.72, 8.13 and 5.00 percentage of weight of earths crust respectively. Nitrogen and Oxygen constitute 78.08 and 20.95 percentage of dry air by volume respectively. 1-2 Materials • Tools, implements, articles, etc. needed to make or do something • Matter, Substance, Stuff, Fabric, … • Have extension in space and time • Inertia from their mass • Exert gravitational attraction • A specialized form of energy 300 => 400 ppm Greenhouse gases: Water vapor (H2O), Carbon dioxide (CO2), Methane (CH4), Nitrous oxide (N2O), Ozone (O3), CFCs Materials Science and Engineering Content 魏茂國 Historical perspective Materials science and engineering Why study materials science and engineering? Classification of materials Advanced materials Modern Materials needs Processing/structure/properties/performance 16 Materials Science and Engineering • Materials science deals with basic knowledge about the internal structure, properties and processing of materials. • Materials engineering deals with the application of knowledge gained by materials science to convert materials to products. • Combined knowledge of materials enables engineers to convert materials into the products needed by society. Basic Knowledge of Materials Resultant Knowledge of Structure and Properties Materials Science Materials Science and Engineering Materials knowledge spectrum. Applied Knowledge of Materials Materials Engineering Inter-disciplinary or multi-disciplinary 材料科學與工程 • 研究製程、結構、性質及性能表現等 四者之間的關係 • • • • 兼及理論與應用,橫跨工程與科學 具跨領域的整合性,在高科技產業中扮演關鍵的地位 是電子、資訊、通訊、航太、機械及光電產業的基礎 研究領域: 陶瓷材料 金屬材料 高分子材料 複合材料 半導體及電子材料 生物材料 • 材料為「工業之母」 Materials Science and Engineering Materials Science 魏茂國 Structure - The structure of a material usually relates to the arrangement of its internal components. - Microscopic means that which is subject to direct observation using some type of microscope. - Structural elements that may be viewed with the naked eye are termed macroscopic. Property - A property is a material trait in terms of the kind and magnitude of response to a specific imposed stimulus. - Definitions of properties are made independent of material shape and size. (not always true) 20 Six important properties in solid materials • Mechanical properties – relate deformation to an applied load or force. • Electrical properties relate the stimulus to an electric field. • Thermal properties: heat capacity, thermal conductivity. • Magnetic properties – demonstrate the response of a material to the application of a magnetic field. • Optical properties – relate the stimulus is electromagnetic or light radiation. • Deteriorative properties – indicate the chemical reactivity of materials. 21 Materials Science & Engineering • Study and establish the interrelationship between processing, structure, properties, and performance – The structure will depend on how it is processed – The properties will depend on its structure – The performance will be a function of its properties. 22 Structure, Processing, & Properties • Properties depend on structure ex: hardness vs. structure of steel (d) Hardness (BHN) 6 00 5 00 4 00 (c) (a) (b) 4 mm 3 00 2 00 30 mm 30 mm 100 0.01 0.1 30 mm 1 10 100 1000 Cooling Rate (ºC/s) • Processing can change structure ex: structure vs cooling rate of steel 23 Optical properties vs. Structures 魏茂國 Materials Science and Engineering Transmittance of aluminum oxide The structures of the three specimens are different in terms of crystal boundaries and pores, which affect the optical transmittance properties. - Single crystal (sapphire) (left): transparent. - Polycrystal and fully dense (nonporous) (center): translucent. - Polycrystal with 5% porosity (right): opaque. 24 Why study MSE? • Be a material scientist and/or engineer • All products involving materials • Selection of right materials – Ideal combination of properties – compromise – Deterioration of materials – Economics –cost • Familiar with MSE – Making judicious choice – Creating or development new materials 25 Materials Science and Engineering Content 魏茂國 Historical perspective Materials science and engineering Why study materials science and engineering? Classification of materials Advanced materials Modern Materials needs Processing/structure/properties/performance 26 Classification of Materials • Metals, Ceramics, Polymers, composites, electronics, (Biomaterials) • Element, compound, mixture, alloy • By Form: powder, fiber, film, bulk • By Phase: solid, liquid, gas, plasma (地水火風) • By Crystallinity: crystalline, amorphous • By Chemistry: Organic, Inorganic • By property – Electrical: conductor, insulator, semiconductor, superconductor – Magnetic, optical, thermal, mechanical, sensor, catalysis Periodic Table http://www.chemicool.com/ http://www.chemicool.com/ 29 Types of Materials • Metals: – Strong, ductile – High thermal & electrical conductivity – Opaque, reflective. • Ceramics: ionic bonding (refractory) – compounds of metallic & non-metallic elements (oxides, carbides, nitrides, sulfides) – Brittle, glassy, elastic – Non-conducting (insulators) • Polymers/plastics: Covalent bonding sharing of e’s – Soft, ductile, low strength, low density – Thermal & electrical insulators – Optically translucent or transparent. 30 Classification of Materials 魏茂國 Metals - Metals are composed of one or more metallic elements, and often nonmetallic elements in relatively small amounts. - Atoms in metals and their alloys are arranged in a very ordered manner, and relatively dense. - They have large numbers of nonlocalized electrons; these electrons are not bound to particular atoms. - Properties: good conductors of electricity and heat, not transparent to light - Quite strong, yet deformable, which accounts for their extensive use in structural applications. - Metals and alloys are commonly divided into two classes. 1. Ferrous metals and alloys 2. Nonferrous metals and alloys 31 Classification of Materials Materials Science and Engineering 魏茂國 Ceramics - Ceramics are compounds between metallic and nonmetallic elements. They are most frequently oxides, nitrides, and carbides. - Ceramics have exhibited extreme brittleness (lack of ductility) and are highly susceptible to fracture. - Ceramics are typically insulative to the passage of electricity and heat, and are more resistant to high temperatures and harsh environments. - Advantages for engineering applications 1. Light weight 2. High strength and hardness 3. Good heat and wear resistance 4. Reduced friction. 5. Insulative properties 32 Classification of Materials 魏茂國 Polymers - Polymers include the familiar plastic and rubber materials. They are organic compounds that are chemically based on carbon, hydrogen, and other nonmetallic elements. - Have low densities and may be extremely ductile and pliable (i.e., plastic). - Relatively inert chemically and unreactive in a large number of environments. - One major drawback to the polymers is their tendency to soften and/or decompose at modest temperatures. - They have low electrical conductivities and are nonmagnetic. Fig. 1.10 Several common objects that are made of polymeric materials: plastic tableware, billiard balls, a bicycle helmet, two dice, a lawn mower wheel, and a plastic milk carton. 33 Room-temperature Density of various materials fig_01_03 Stiffness value for various materials fig_01_04 Strength values for various materials fig_01_05 Fracture toughness for various materials fig_01_06 Electrical conductivity for various materials fig_01_07 The Materials Selection Process 1. Pick Application Determine required Properties Properties: mechanical, electrical, thermal, magnetic, optical, deteriorative. 2. Properties Identify candidate Material(s) Material: structure, composition. 3. Material Identify required Processing Processing: changes structure and overall shape ex: casting, sintering, vapor deposition, doping forming, joining, annealing. 39 ELECTRICAL • Electrical Resistivity of Copper: 6 (10-8 Ohm-m) Resistivity, r 5 4 3 2 1 0 -200 -100 0 T (ºC) • Adding “impurity” atoms to Cu increases resistivity. • Deforming Cu increases resistivity. 40 • Space Shuttle Tiles: THERMAL -- It decreases when you add zinc! Thermal Conductivity (W/m-K) -- Silica fiber insulation offers low heat conduction. • Thermal Conductivity of Copper: 100 mm 400 300 200 100 0 0 10 20 30 40 Composition (wt% Zinc) 41 MAGNETIC • Magnetic Storage: vs. Composition: -- Adding 3 atomic % Si makes Fe a better recording medium! Magnetization -- Recording medium is magnetized by recording head. • Magnetic Permeability Fe+3%Si Fe Magnetic Field Fig. 20.23, Callister & Rethwisch 8e. 42 DETERIORATIVE -- causes cracks! • Heat treatment: slows crack speed in salt water! crack speed (m/s) • Stress & Saltwater... 10-8 10-10 “as-is” “held at 160ºC for 1 hr before testing” Alloy 7178 tested in saturated aqueous NaCl solution at 23ºC increasing load -- material: 4 mm 7150-T651 Al "alloy" (Zn,Cu,Mg,Zr) 43 Materials Science and Engineering Content 魏茂國 Historical perspective Materials science and engineering Why study materials science and engineering? Classification of materials Advanced materials Modern Materials needs Processing/structure/properties/performance 44 Future Trends • Composite Materials Fiber reinforced plastics are primary products. On an average 3% annual growth from 1981 to 1987. Annual growth rate of 5% is predicted for new composites such as Fiberglass-Epoxy and GraphiteEpoxy combinations. Commercial aircrafts are expected to use more and more composite materials. 1-14 Future Trends • Electronic Materials Use of electronic materials such as silicon increased rapidly from 1970. Electronic materials are expected to play vital role in “Factories of Future”. Use of computers and robots will increase resulting in extensive growth in use of electronic materials. Aluminum for interconnections in integrated circuits might be replaced by copper resulting in better conductivity. 1-15 Future Trends • Smart Materials : Change their properties by sensing external stimulus. Shape memory alloys: Strained material reverts back to its original shape above a critical temperature. Used in heart valves and to expand arteries. Piezoelectric materials: Produce electric field when exposed to force and vice versa. Used in actuators and vibration reducers. MEMS and Nanomaterials • MEMS: Microelectromechanical systems. Miniature devices Micro-pumps, sensors • Nanomaterials: Characteristic length < 100 nm Examples: ceramics powder and grain size < 100 nm Nanomaterials are harder and stronger than bulk materials. Have biocompatible characteristics ( as in Zirconia) Transistors and diodes are developed on a nanowire. Competition of six major materials in USA Case Study – Material Selection • Problem: Select suitable material for bicycle frame and fork. Steel and alloys Wood Low cost but Heavy. Less Corrosion resistance Light and strong. But Cannot be shaped Carbon fiber Aluminum Ti and Mg Reinforced alloys alloys plastic Very light and Light, moderately Slightly better strong. No Strong. Corrosion Than Al corrosion. Resistance. alloys. But much Very expensive expensive expensive Cost important? Select steel Properties important? Select CFRP Materials Science and Engineering Content 魏茂國 Historical perspective Materials science and engineering Why study materials science and engineering? Classification of materials Advanced materials Modern Materials needs Processing/structure/properties/performance 51 fig_01_11a fig_01_11b fig_01_11c fig_01_11d SUMMARY Course Goals: • Use the right material for the job. • Understand the relation between properties, structure, and processing. • Recognize new design opportunities offered by materials selection. • Understand materials science and engineering. 56 Home Work #1 1. Write a short essay on “Why do you choose MSE as your major?” and “What are the goals of your college education?” 2. Take a close look of your bicycle. What are the major parts or components in the product? What materials are used to make the components in terms of elements and type of materials? Why these materials are used? (at least 500 words for each assignment) 57