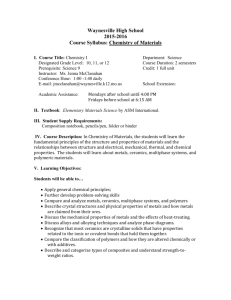

Properties of materials: more than physical and chemical 1

advertisement

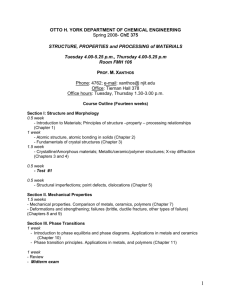

These aren’t really ‘properties’ – more like definitions that relate to what’s happening microscopically. The goal here is to relate structure to properties. The kinds and relative count of elements, ions or other constituents in a material; chemical formula, percent in an alloy, etc. Note that a single composition can have different structures, for instance allotropes of sulfur or polymorphs in ironcarbon systems. The basic starting point is: Metals Ceramics covalent Polymers Composition metallic elements Bonding metallic metals + nonmetals ionic & carbon, hydrogen covalent Atomic scale order; the manner in which atoms or ions are spatially arranged. It is defined in terms of unit cell geometry. A material with long-range order is called crystalline (contrasted with amorphous). The structural features that can be seen using a microscope, but seldom with the naked eye; ranges from glassy to crystalline; includes grain boundaries and phase structures. These are the standard properties that we teach in chemistry class. Solid, liquid or gas; not as simple as it may seem. Mass of a material per unit volume. Low density, high strength materials are desirable for manufacturing aircraft and sporting equipment. The physical attraction for iron, inherent in a material or induced by moving electric fields. Iron, cobalt, nickel and gadolinium are inherently ferromagnetic. The maximum amount of a solute that can be added to a solvent. Solubility is complex in some solid materials, for instance the ones that form eutectic mixtures; a good starting point to discuss complex phase diagrams. Resistance of a material (usually liquid) to flow. Plastics and glasses become less viscous with increasing temperature. The concepts of stress, strain, elasticity, deformation and failure are necessary to understand and interpret mechanical properties. The ability of a material to be reshaped in all directions (plastic deformation) without failure; related to ductility and sometimes called workability; an important characteristic of metals. The ability of a material to change shape (deform) usually by stretching along its length; closely related to tensile strength. Strength is not a precisely defined mechanical property, as there are many types of strength. Collectively, it means the ability of a material to stand up to forces being applied without it bending, breaking, shattering or deforming. The resistance to being permanently deformed or bent; measured by distance of penetration into the material. There are several scales used to measure hardness. A characteristic of a material that relates to its response to sudden blows or shocks. Toughness can be expressed as the amount of energy required for creating or propagating a crack. The absence of ductility; failure by sudden fracture (no plastic deformation); characteristic of ceramic materials. The ability of a material to absorb force and flex in different directions, returning to its original position once the stress is removed. Polymers are desirable for their elasticity. For the sake of this summary, electricity is defined as the flow of electrons. A measure of how easily a material allows electrical current to flow through. Metals like copper, aluminum and iron have much higher electrical conductivities than ceramics, plastics, glass and rubber. The reciprocal of electrical conductivity; a measure of a material’s resistance to the flow of electric current. Resistivity is an important concept in semiconductors; depends on electronic structure, temperature and microstructure. Generally, lack of reactive chemistry is desirable for materials; this is a good place to look through those MSD sheets. A measure of a material’s ability to damage or disrupt the metabolism of living tissue; can be acute or chronic; can be administered by contact, inhalation, ingestion, or injection. The dose makes the poison. Corrosion is an electrochemical process that is closely related to the activity series. An ion high on the list will replace a metal lower on the list. Mg > Al > Zn > Cr > Fe > Sn > Ni > Cu > Ag > Au Corrosion is strongly dependent on environmental variables. A material’s ability to catch fire and burn; important for organic materials and reactive metals. Use in or on the human body without eliciting a rejection response from the surrounding body tissues; includes materials made of polymers, metals, ceramics, and composites. Think about heating a rod: it gets hot, it expands, it conducts heat, it may soften or melt. The efficiency of a material in absorbing heat. High specific heat means a material heats fast and cools down fast. By definition, the specific heat of a material is the energy required to raise the temperature of 1 g of that material by 1 °C. Nearly all materials expand when heated and contract when cooled. The extent to which this happens is the coefficient of thermal expansion. Bridges are designed with expansion joints so they don’t buckle due to thermal expansion. Thermal conductivity is the rate at which heat flows through a material. It depends on the flow of both electrons and phonons. The temperature at which liquid begins to form as a material is heated. Not all materials have distinct melting points, and many materials have phase transition temperatures in which crystal structure changes.