GENCO-III

advertisement

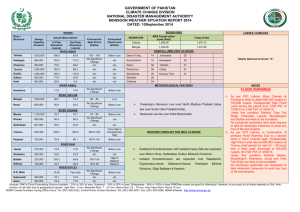

PRESENTATION BY CHIEF EXECUTIVE OFFICER NORTHERN POWER GENERATION COMPANY (GENCO-III) Workshop on Power Sector Reforms On 11.11.2010 to 12.11.2010 at WAPDA House, Lahore CONTENTS OF PRESENTATION 1. Brief Introduction 2. 3. 4. 5. 6. Profile of Board of Directors Technical Data of Units at TPS, Muzaffaragrh Effects of Furnace Oil Firing on Boiler Reasons of De-rated Capacity Rehabilitation of TPS, Muzaffargarh under USAID Energy Support Program. 7. Solutions and Suggestions BRIEF INTRODUCTION Northern Power Generation Company Limited (NPGCL) is a Public Limited Company, incorporated on October 15, 1998 under the Companies Ordinance 1984, having Power Generation facilities at various of locations of the province of Punjab. It consists of eight generating blocks having total derated capacity 1530MW. (Muzaffargarh 1130MW, NGPS Multan 60 MW, SPS Faisalabad 100MW & GTPS Faisalabad 240MW). Profile of BOD Board of Directors 1. Prof. Abdul Hameed 2. Mr. Abdul Rasheed Mir Qualification T. Exp., Yrs Years with NPGCL M.Sc. Elect. Engg. F.I.E.E(U K) F.INST. E.E.E.(Pa k) Dean, Faculty of Electrical Engg. University of Engineering and Technology Lahore, Director, BOD, TEVTA (2002-04) Chairman, Bismillah Education Trust Regional Director, National Institute of Power (1992-98) Council Member, IEE (UK) Council Member, IEEE (Pak) 08 Years F.CA 14 years as CEO/Director Gray’s Leasing Ltd. 13years as Chairman/Director Friendswear(Pvt) Ltd. 08 Years Board of Directors Qualification T. Exp., Yrs Years with NPGCL 3. Khawaja Muhammad Younis B.Sc. (Honrs) 30 Years as Director, Mahmood Group of Industries, Member Executive Committee (FPCCI), Member Central Executive Committee (APTMA), Director Punjab Social Security Health Management Company, President, D.G.Khan & Bahawalpur Chamber of Commerce & Industry 04 Years 4. Mr. Hammad Ahmad FCMA 20 years in Power Sector 1½ Years 5. Mr. Muhammad Rafiq Butt B.Sc (Electrical) 35 Years as power plant engineer, Presently working as GM (D&D) 1½ Years 6. Mr. Muhammad Naeem Akhtar B.Sc (Mechanical) 33½ Years as power plant engineer, Presently working as CE(MMS) 3 Months 7. Mr. Ghulam Mustafa Tunio B.E (Electrical) 34 years as power plant engineer, Presently working as CEO (GENCO-III) 1½ Years TECHNICAL DATA OF UNITS AT TPS, MZG Description Unit-1 Unit-2 Unit-3 Make TPE RUSSIAN Model K-210-130-8 Unit-4 Unit-5 Unit-6 CHINA N320178/538/538 N210 Steam Turbine Date of installation 09.09.1993 23.03.1994 20.02.1995 23.12.1997 14.02.1995 14.08.1995 Running Hrs since commissioning 109636.51 107735.73 101876.37 88755.64 71050.66 67421.09 Unit generated (MkWh) since commissioning 17938.87 17692.704 15714.124 21294.643 9579.500 8769.305 2 2 2 1 1 1 Last date of MOH 14.09.2005 03.06.2007 02.02.2009 21.07.2004 01.12.2003 29.01.2003 Last date of ABI 12.08.2008 11.11.2009 22.06.2010 22.07.2010 13.11.2009 15.11.2009 ABI Overdue 14 Months - 3 Months 9 Months - - Running Hrs since last major overhauling 33669.46 22311.12 10223.73 41087.86 35195.95 40398.21 Designed efficiency 36.77 36.77 36.77 36.70 31.65 31.65 Present Efficiency 29.18 29.58 30.69 31.51 26.80 27.25 Designed Heat Rate (Btu/kWh) 9286.98 9286.98 9286.98 9304.53 10797.47 10797.47 Present Heat Rate (Btu/kWh) 11694.96 11536.85 11120.70 10831.48 12734.91 14369.40 Designed Load (MW) 210 210 210 320 200 200 Present Load (MW) 110 180 160 200 95 95 No. of Major Overhauling EFFECTS OF FURNACE OIL FIRING ON BOILER The machines of GENCO-III steam units were designed for mix fuel (gas + furnace oil) and gas turbines were designed for gas operation but due to non availability of gas fuel, plants of GENCO-III are being operated on furnace oil since long. The continuous oil firing has caused enormous effects on the performance of machines causing the reduction in the de-rated capacity. The efforts are being made to recover the lost capacity by carrying out the rehabilitation / replacement of deteriorated / damaged components of the plants. The affected components of boiler due to continuous oil firing are shown in following pictures. DETERIORATED CONDITION OF BOILER COMPONENTS OF Block No.1 – TPS, Muzaffargarh Unit No. 1, 2 & 3 210-MW each Russian Make SCALE FORMATION ON HEATING SURFACES Block No.2 – TPS, Muzaffargarh Unit No. 4 320-MW Chinese Make DETERIORATED CONDITION OF BOILER COMPONENTS OF Block No.3 – TPS, Muzaffargarh Unit No. 5 & 6 200-MW each Chinese Make REASONS OF DE-RATED CAPACITY BLOCK-1 Block No.1, comprising of Units No.1, 2 & 3, was commissioned in 1993, 1994 & 1995, respectively. These units have operated for 109636, 107735 & 101876 running hours since their commissioning. Due to aging factor, wear & tear and continuous furnace oil firing since last five (5) years, The boilers of these units have been badly affected/deteriorated. The following jobs are necessary to be carried out in order to operate these units on economical loading i.e. more than 75% of rated load. 03 Sr. No. Major Problems at Unit-1,2&3 TPS M/Garh 01 Boiler super heater tubes leakages. In case load on these units increased above 100MW for unit No.1, 180MW for unit No.2 and 150 MW for unit No.3. The super heaters leakages starts frequently causing the forced shutdown of the units. 02 RAH Cold & Hot elements deterioration and need replacement 03 Replacement of damaged/deteriorated components of ID fans side A&B of all three units. Repair and rehabilitation of flue gases ducts upto the exists point. 04 05 06 07 08 09 10 Rehablitation of soot blowing system of Furnace, Super Heaters, Re-Heaters and Re-generative air heaters Rehabilitation of cooling water system including condenser for improving the vacuum. Chemical treatment of cooling water system Dozing of fuel additive system in the furnace oil in order to minimize the formation of scales on heat transfer surfaces of boiler including super heaters & re-heaters. Replacement of of existing cooling tower fans by new one in order to improve the performance of cooling towers. Modification of Excitation system BLOCK-2 (Unit No.4) Block No.2 comprising of Unit No.4 was commissioned in 23.12.1997. This unit has operated for 88755 running hours since its commissioning. The major overhauling of this unit is overdue but could not be carried out due to non availability of essential spare parts required for major overhauling such as LP Turbine blades of last stages. Due to continuous furnace oil firing at this unit we are facing following problems: (i)- The heating components including economizer, super heaters, re-heaters and regenerator air elements have badly affected due to formation of deposits / scales and a thin layer of scale has developed over the heating surfaces causing the reduction in heat transfer. (ii)- Due to formation of this thick layer of scale, the steam generating capacity of boiler has considerably decreased causing reduction in the load upto 230 MW. Sr. No. 01 02 03 Major Problems at Unit No.4 TPS M/Garh AVR System need to be modified. UPS system need to be replacement by new one LP. Rotor blades of last stages removed and need to be reinstalled by the new one. 04 Air Pre-Heater Elements deterioration due to continuous oil firing. 05 Requirement of Fuel Additive system to minimize the formation of scales on heating surfaces. 06 Rehabilitation of Air/ Flue gas ducts which have been deteriorated/damaged due to continuous furnace oil firing. 07 Requirement of Special Cooling Water Treatment system BLOCK-3 (Unit No.5&6) Block No.3 comprising of Units No.5 & 6 was commissioned in 14.02.1995 & 14.08.1995 respectively. These units have operated for 71050 & 67421 running hours, since their commissioning. These units are facing following problems: These units are Chinese made and since their commissioning, the availability, reliability and loading of the units remained less as compared with the installed capacity. Due to continuous furnace oil firing following major faults have been developed. Sr. No. Major Problems at Unit-5&6 TPS M/Garh. 01 I. D. Fan Rotor/Impeller need to be replaced. 02 G.R.C. Fan Impeller/Rotor problem 03 Cooling Tower Fan Gear Box problems 04 Air Pre-heater Elements Hot end, intermediate & cold end layers deterioration/damaged 05 Steam Coil Air Heaters deteriorated 06 Frequent Economizer Tubes leakages in case the load is increased above 100MW. 07 IP & LP Turbine Rotors require replacement. 08 Rehabilitation of Air/Flue gases ducts and rehabilitation of soot blowing system of furnace and regenerative air heaters. 09 Fuel Additive System is required to minimize the formation of scales on heating surfaces. 10 Feed Water pumps Hydraulic coupling problems Block-4 & 6, GTPS, Faisalabad The GTPS power plant was commissioned in 1975 and its CCP was commissioned in 1994. The gas turbines of the plant are being operated in simple & combined cycle. But due to non availability of Gas these machines are being operated on Diesel Fuel. Unit Name Type COD/Age Installed Capacity Dependable Capacity Designed Efficiency (%) Present Efficiency (%) Fuel FSA GT-1 Gas Turbine 09.03.1975 25 19 27.60 17.30 GAS/HSD Under Negotiation GT-2 Gas Turbine 10.03.1975 25 19 27.60 19.67 -DO- -DO- GT-3 Gas Turbine 04.05.1975 25 19 27.60 20.95 -DO- -DO- GT-4 Gas Turbine 06.03.1975 25 19 27.60 22.39 -DO- -DO- GT-5 Gas Turbine 31.07.1975 25 23 27.60 21.64 -DO- -DO- GT-6 Gas Turbine 05.07.1975 25 23 27.60 20.78 -DO- -DO- GT-7 Gas Turbine 10.07.1975 25 23 27.60 21.76 -DO- -DO- GT-8 Gas Turbine 14.11.1975 25 23 2760 21.61 -DO- -DO- CCP-9 Combine cycle 28.12.1994 44 42 - - -DO- -DO- THERMAL POWER STATION FAISALABAD. Block-5, SPS, Faisalabad. It comprises of two steam units of 2x66 MW installed capacity. These units were commissioned in 1966 and 1967 respectively. The units have completed their useful life but due to better technology and continuous maintenance efforts made by the engineers and staff of the plant these units are in operation since 43 years which is a record. Due to continuous oil firing the condition of boiler has deteriorated and its major components such as flue gases ducts, air pre heater structures, economizer and super heaters have become weak. The following are the major problems. Sr. # 01 02 03 04 05 Major problems at SPS, Faisalabad Condenser Tubes fouling Boiler Heating surfaces scaling Re-generative air heater deterioration Weak super heaters Weak economizers Remarks UAE has gifted 320MW power plant, the shifting of the plant, its installation and commissioning is in the process in the vicinity of TPS Faisalabad. After the commissioning of the gifted power plant the existing steam units will be standby. Block-7, NGPS-Piranghaib, Multan NGPS Multan comprises 04 units. These units were commissioned in 1960 and 1963. The unit has completed their useful life and at present these units are being operated due to load crises at derated loading of 30MW each, the efficiency and availability of these units is poor but due to load requirement of the system these units are being operated as per demand of NPCC. Due to non availability of gas boilers are operated on furnace oil since long, the continuous furnace oil firing has also badly affected the regenerative air heater elements, flue gases ducts, economizer and super heaters. The unit No.2 has already been cannibalized. Whereas unit No.3 is under shutdown due to fault in its reduction gear. Sr. No. Major problems of NGPS, Multan Remarks 01 02 03 04 05 Air Pre Heater/Flue gas duct problems Economizer frequent leakages Reduction gear fault Chimney Stack deteriorated. Super heaters weak/frequent leakages in case load increased above 30MW. Cooling water system damaged/deteriorated. Installation of a new CCPP 350MW has planned, PC-I of the project has been prepared and it is in the Ministry of Water & Power for further process. The new plant will be installed in the available area of NGPS and the existing plant will be retired very soon. 06 Rehabilitation of TPS Muzaffargarh The rehabilitation program of GENCO-III especially for TPS, Muzaffargarh has been signed with the USAID. The rehabilitation is under process in the light of agreement FARA and recently a MOU has been signed between WAPDA CCC and GENCO-III regarding the procurement of the spares required for rehabilitation of the TPS, Muzaffargarh. After completion of Rehabilitation, Muzaffargarh, “INSHA ALLAH” will Dependable Capacity of 1130 MW . the TPS, regain its STATUS OF MATERIAL PROCUREMENT FOR REHABILITATION OF TPS, MZG UNDER FARA-USAID Item # Unit # Item Description Present Status 1 1,2&3 Rehabilitation of Boiler super heater tubes Material has arrived at Karachi Port and is to overcome failure of tubes expected to be received at site in November2010. Shutdown of each machine has been planned for 60 days to replace damaged tubes of super heaters. 2 1,2&3 Special Cooling Water Treatment. 3 1,2&3 4 1,2&3 5 1,2&3 Use of Fuel Oil Additive as on Unit-4 (200 Case of procurement is under process Tons). Replacement of Cold layer element for Material received and installed. RAH (1 set). Modification of Excitation system (1 set). Case of procurement is under process 6 1,2&3 Electric Motor for C.T. Fan (02 No). Case is under process for placement of Purchase Order. 7 1,2&3 Electric Motor for GRC fan. (01 No). Case is under process for placement of Purchase Order. 8 1,2&3 D.C. Storage Batteries (01 Set). Material received and installed. 9 1,2&3 220KV Circuit Breaker SF6 type (06 No). Case is under process for placement of Purchase Order. Case of procurement is under process Item # Unit # Item Description Present Status 10 4 Re-blading of LP. Rotor (LP Turbine Tender is under scrutiny. Rotor blades of row (6&7), pins & locking device). Air Pre-Heater Elements Case is under process for issuance of (Intermediate) (02 set). Purchase Order. 11 4 12 4 Use of Fuel Oil Additive (100 Ton). 13 4 14 4 Special Cooling Water Treatment as Case is under process. being used at IPP’s. Up-gradation of AVR System (01 set). Case is under process. 15 4 Changing of UPS 1&2. (01 set). Case is under process for issuance of Purchase Order. 16 4 DEH (01 set). Tender No.MZG-26 to be opened on 24.11.2010. 17 4 Up-gradation of FSSS System (01 set). Case of procurement is under process Case of procurement is under process. Item # Unit # Item Description Present Status 18 4 Up-gradation of TSI system BNC Case is to be initiated. 3300 (Turbine Supervisory Instrument) (01 set). Training and software/hardware cost Case is to be initiated. for CMMS and off-line efficiency monitoring system. All Units 19 1-6 20 5-6 I.D.Fan Rotor/Impeller along with The Purchase Order has been placed and Housing and Dampers (04 Set). material is awaited to be received at site. 21 5-6 Case is under process. 22 5-6 23 5-6 24 5-6 Air Preheater Elements Hot End, Intermediate & Cold End layers along with seals for both Units (04 Set). Procurement of G.R.C. Fan Impeller/Rotor (01 Set). Procurement of Cooling Tower Fan Gear Box & its parts. (06 No. gear box). Economizer Tubes for both Units (02 Set). 25 5-6 Special Cooling Water Treatment. Case is under process. 26 5-6 Use of Fuel Oil Additive (150 Ton). Case is under process. 27 5-6 IP Turbine Rotor (01 No). Case is under process. 28 5-6 Replacement of Damaged Exhaust Case is under process. flue gas ducts of material Russian Grade Steel sheets (50 M.T). Tender is under scrutiny. Tender is under scrutiny. Tender No. 25.11.2010. MZF-27 to be opened on Item # Unit # Item Description Present Status 29 5-6 Conversion of Boiler Ignition System from Natural Gas to ICB Tenders being prepared by NPGCL (GENCOHSD/Furnace Oil. III). 30 5-6 Turbo-Generator Bearings (09 Nos). Case is under process. 31 5-6 Hydraulic coupling of Boiler Feed Water Pumps (01 No). ICB Tenders being prepared by NPGCL (GENCOIII). 32 5-6 Modification of Excitation System (02 set.) ICB Tenders being prepared by NPGCL (GENCOIII). 33 5-6 Procurement of 0.4KV Motors for Cooling Towers Fan and Tender No.T-1447 to be opened on 30.11.2010 APH (02 No) 34 5-6 Procurement of 6.6KV Motor for C.W.Pumps, CP, ID Fan, Tender under scrutiny. FD Fan & BF Pumps (05 No). 35 5-6 Procurement of 6.6/0.4KV Breaker (5 No. 6KV breaker, ICB Tenders being prepared by NPGCL (GENCO18Nos. 0.4Kv Breakers). III). 36 5-6 Protection Relay for Generators. ICB Tenders being prepared by NPGCL (GENCOIII). 37 5-6 MK Breakers, Seal Oil Coolers, PMG. Purchased Order has been placed. 38 5-6 39 5-6 Supply, Installation, Commissioning & Testing of complete distribution control system (DCS) including field equipment ICB Tenders being prepared by NPGCL (GENCOlike sensors, transmitter & actuators etc for turbine governing III) system DEH-III and Boiler Turbine Auto regulation system YEWPACK-II Rehabilitation of Furnace safety Supervisory System (FSSS) ICB Tender in process. including Furnace camera, flame monitoring & ignition system SOLUTIONS & SUGGESTIONS 1. MIX FIRING (FURNACE OIL & GAS) i. ii. iii. iv. 2. In order to minimize the damages to boiler due to continuous furnace oil firing of high sulpher oil, it is suggested that at least 200mmcfd gas may please be arranged/got approved by competent authority for Muzaffargarh to have mix/dual firing. It will not only improve the efficiency of the plant but reliability, availability & loading will also be improved. Forced shut downs will also be considerably reduced. Arrangement of sufficient quantity of LSFO instead of HSFO. The approx: quantity of furnace oil per month is 150,000 M.Ton in case of all units are in operation. Supply of furnace oil through pipeline as it is being supplied by PSO to KAPCO & Lalpir. Handing over of existing supply system of furnace oil to M/s PSO on mutual agreement which is under the process. PROCUREMENT PROBLEMS (i) (ii) The procurement process of spare parts be expedited and it is suggested that ICB tender be invited by GM(Thermal) as in the past and send to end user of scrutiny & evaluation. As such the most of spares are common for all the three GENCOs, in case each genco is processing the case individually, there will be difference in the rates quoted by the bidders causing audit problems at later stage. There is no set up for the procurement of material through ICB at GENCOs level. In the new set up the target of procurement as per time schedule of USAID could not be achieved because the lot of time has already been wasted in shifting of files and corrigendum issued regarding the extension an opening date etc by the Head Office. 3. Difficulties in Evaluation of ICB Tenders International tenders were opened by Tender Opening Committee on due date i.e. 31.08.2010, in the office of General Manager (Thermal) PEPCO, Wapda House, Lahore for procurement of 6.6 kV auxiliary motors Unit # 5 & 6. Following six firms participated in the tender. i) M/S Imperail Tender Czech Republic M/S Hi Tech system, Lahore. ii) M/S Excell Techno Solutions UAE. M/S Excell Techno Services, Lahore. iii) M/S Milequip, China M/S SGW(PVT) LTD, Lahore iv) M/S GANSU SHUNGLIN, China M/S I.J. International Lahore v) M/S HIPCE China M/S Al-Tariq, Karachi vi) M/S HPE China M/S Albario Lahore Principal. Representative Principal Representative Principal Representative Principal Representative Principal Representative Principal Representative Rs.20,581,715/- Ist Rs.22,662,519/- 2nd Rs.28,577,816/- 3rd Rs.31,205,711/- 4th Rs.45,318,788/- 5th Rs.47,964,657/- 6th •First lowest M/s Hi Tech System Lahore offered Check republic made motors (other than OEM) amounting Rs.2,05,81,715/•OEM made motors was offered by M/s Al-Tariq Karachi which was fifth lowest amounting Rs.4,53,18,788/•Cost difference in first lowest (other than OEM) and OEM offer was Rs.2,47,37,073/- which is almost 120% high as compared to 1st lowest. •PPRA Rules require to recommend the lowest bidder but the risk of material quality and dimensions is involved in equipment other than OEM. Due to these problems the procurement of spare parts is delayed which ultimately results delay in completion of rehabilitation jobs. 4. USE OF CHEMICALS i. ii. Use of Fuel Additive Water Treatment in C.W. system. 5. INSTALLATION OF TUBE WELLS, IN AREA OF POWER HOUSE. 6. TIMELY SHUTDOWN OF THE UNITS FOR MAINTENANCE. 7. RECRUITMENT OF STAFF ON MERIT WITHOUT ANY INFUENCE. 8. STOPPAGE OF FREQUENT POSTING & TRANSFER OF STAFF/OFFICERS. 9. ESTABLISHMENT OF SEPARATE GENCO TO LOOK AFTER THE MANAGEMENT OF NANDIPUR, CHICHOKIMALIAN AND RENTAL POWER PLANTS IN ORDER TO REDUCE THE EXCESSIVE WORK LOAD ON GENCOIII WHICH IS OVER LOADED AS COMPARED WITH OTHER GENCOS. 10. THE SALARY AND OTHER BENEFITS OF GENCOs BE MATCHED WITH IPPs TO STOP THE DRAINAGE OF SKILLED STAFF.