Introduction to Requirements

advertisement

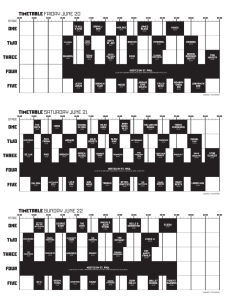

Developing the MBSE Approach Tony Ramanathan Principal Engineer Network Rail 1 Agenda The Railway System Investment Governance GRIP Asst Life Models / Analysis used Interface Management – why we need Modelling Modelling Tools Design Handbook inc the Building Blocks 2 The people, The process applied, The systems used 3 Project Governance - GRIP “Project Life-Cycle” Governance for Railway Investment Projects (GRIP) There are Eight GRIP Stages Pre-GRIP A RUS scheme is outside of Project Governance and is between 5 to 7 years prior to GRIP 1 4 Analyses Used in Systems Engineering Layout Capacity Signalling Capacity Passenger Demand Safety Risk Performance Evaluation Train Service Specification Timetable Development Layout Capacity Electrification Capacity System Capability Timetable Robustness Infrastructure Loading System Reliability Life Cycle Costs 5 Asset Life Railway System - Designed Asset Life s Track / Signal 30 to 35 Y Co m ck Tr a Si gn al s ins TOC Franchise Between 5Y to 18 Y Trains 35Y Tr a Po we r Bu i ld in gs St ru ctu re s Years 140 120 100 80 60 40 20 0 Pl an t Network RUS 6 to 20 Y Structures 120Y Asset Types 6 Interface Management - train infrastructure interfaces • OLE Contact • Traction Power • EMC • Customer Information Systems (CIS) • Lineside Infrastructure • Signalling & Telecoms • Passengers behaviour • Gauging Clearance • Kinematic Envelope (KE) • Train Detection • Track Conditions • Track Design/Quality • Drainage • Tonnage passing (load) • Wheel/ Rail Interface • Axle Load • Route availability (RA) / Allowable Speeds • Platform Occupation/ Dwell Times • Platform Length/SDO • Stepping Distance • Station/ DDA Compliance 7 Modelling Tools Systems Analysis Section number to go here Models often consider differing Time Horizons Full UK ICM Route level TRAIL RailSys Spatial Representation* Scheme level Asset level OSLO CUI SPA Pedflow VTSIM EMI Mins Hours Days Periods Years Multi Years Analysis Time Horizon * Spatial representation within a single model 9 SA Approach towards Option Selection Preliminary Assessment Systems Capability Modelling Option 1 Capability: Capacity Journey Times Power Reliability Maintenance Construction Whole life cost Option 1 Capability: ‘Favoured Option’ Option 2 Capability: ?Capacity Journey Times ? Power Reliability Maintenance Construction Whole life cost Option X Capability: Capacity ?Journey Times ?Power Reliability ? Maintenance Construction Whole life cost Requirements & Option Validation: Capacity Journey Times Power Reliability Maintenance Construction Whole life cost SPA Capacity Journey Times Power Reliability Maintenance Construction Whole life cost Option Selection RailSys OSLO Option X Capability: Ops & Perf. Engineering Eng Policy Feasibility TIP TRAIL Legion Option Capability: Capacity Journey Times Power Reliability Maintenance Construction Whole life cost LCC 10 Typical System Breakdown Structure (SBS) 11 TRAIL (Transportation Reliability, Availability and Integrated Logistics) Timetable Infrastructure Rolling stock Operations TRAIL discrete event simulator PPM Lateness Analysis Delay Analysis Infrastructure Performance Operations Performance 12 What about RailSys? • RailSys is used to provide the ‘operations tick in the box’ for any scheme • Provides a very powerful visualisation of a timetable • Can be used to identify detailed train path routeing and permits detailed event scenario modelling • It does not do PPM • Of note for engineers; the complexity within the model can vary (even if the model is compliant to NR Opns Build Ver6) • Simple models are normally optimistic • trains may exhibit movement behaviour which the driver / signaller might not be able to emulate in real life 13 Capacity Modelling Thameslink KO2 – The need for ATO Crossrail – Scheme Performance Assessment Existing Layout ERTMS – Braking Curve Proposed Layout Reading – Capacity Utilisation Index 14 SPA Process Model Build Signalled Infrastructure SPAR Build Scheme Model Signalling Controls Rolling Stock Performance Calculation Database Technical Platform Reoccupation Journey Times Train Service Specification Date 00.00.00 Scheme Performance Assessment Report Junction Margin Professional Driving Policy Additional Timetable / Infrastructure Technical Headway Rules Of The Plan (ROTP) Sectional Running Times Capacity Utilisation Timetabled Model Presentation title to go here OSLO Support Capacity Utilisation 15 Key contacts Specialist within Network Rail Nigel Best – TRAIL, RAILSYS, RAM, FMECA Clare Waller – Timetable Maya Petkova – EMC Mark Burstow – Wheel / rail dynamics Caroline Lowe – Climate + Asset specialist Gauging Power Signalling Telecoms Level Crossings 16 System Design Handbook Links work only in Presentation Mode Section 1 What is SE Section 2 Intro to SE Teams Section 6 Requirements Section 5 Building Blocks The people, The process applied, The systems used Section 3 GRIP, P Approval & Acceptance Section 4 System Integration 17 PSE – Building Blocks (guidance) (Links work in Presentation Mode) Introduction to Building Blocks PSE Schemes Resource estimating PRS user guide Application of Standard Designs Main Line Stabling Sidings Generic Train Infrastructure Interface Specification + Presentation Layout Capacity Signalling Capacity Passenger Capacity System Safety Timetable Robustness Terminal Stations Line Speed & Journey Time Improvements + Presentation Layout Development Workshops Electrification Capacity System Capability Freight Distribution Depots Rail Maintenance Depots Route Integration System Maintenance System Reliability Life Cycle Cost Consideration for Gradients / Curves + Presentation Equality Act 2002 (DDA) Undertaking a Pre Grip Evaluation Light Rail + Presentation Junction Evaluation + Presentation Introduction To Station Design 18 Typical System Level Railway Functional Block Diagram (FBD) ERTMS Train Control System Operational Architecture - basic arrangement R M- Trainborne Operational Rules JRU Cab DMI R M- GS Trainborne GSMR voice radio Odometry Level crossings Train detection MSC Points Outdoor train control system equipment FTN Possession Mangement Trackside BTS GSM-R FTN Balise Level crossing CCTV Hand portable FTN BSC Trainborne GSMR data radio EVC Balise reader R M- GS Units likely to be be colocated Interface to traction and braking Driver GS Other trackside controlled objects Lineside telephones FTN FTN Track worker FTN FTN FTN Signalling System Interlocking RBC Technician Technicians Interlocking data logger Signaller CCTV level crossing supervision Operational Rules Train control system indoor equipment RBC data logger Signallers interface panel or VDU including train describer Operators RBC interface Voice call logger Signallers operational voice comms MMI Signallers GSM-R voice interface Operators MMI Possession Mangement Automatic train management systems e.g ARS Public Switched Telephone Network SMART/TRUST/CCF Controller Business systems and train planning including passenger information systems 19 Design for Reliability TRAIL (Transportation Reliability, Availability and Integrated Logistics) Timetable Infrastructure Rolling stock Operations TRAIL discrete event simulator PPM Lateness Analysis Delay Analysis Infrastructure Performance Operations Performance TRAIL Model: Options Evaluation System Diagrams DESIGN for RELIABILITY Modify System Configuration Use alternative Asset types Control Key Processes FMS / TRUST Data Route FMECA (Tech. & Ops) Introduce Condition Monitoring Enhance Maintenance Cause & Effect Workshops: Reliability Data Hdbk Engineering Maintenance Operations Improve Operational Plans 20