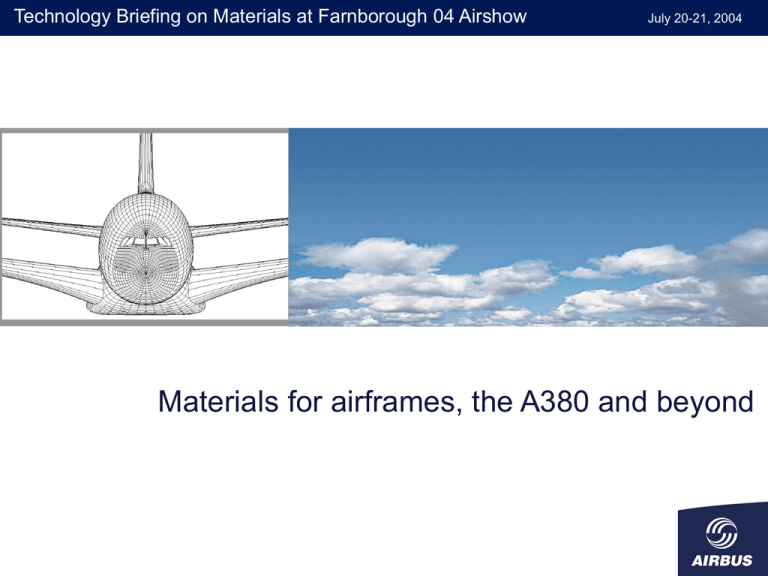

Materials for airframes, the A380 and beyond

advertisement

Technology Briefing on Materials at Farnborough 04 Airshow July 20-21, 2004 Materials for airframes, the A380 and beyond Technology Briefing on Materials at Farnborough 04 Airshow July 20-21, 2004 Presented by Alain Garcia Executive Vice President Airbus Engineering Jürgen Klenner Senior Vice President Airbus Engineering Materials for airframes, the A380 and beyond Superior airframe: Airbus vision CUSTOMER Maintenance free airframe Highest performance Environmentally friendly airframe AIRBUS 3 Materials for airframes, the A380 and beyond ENVIRONMENT The Airbus airframe philosophy Airbus sustained leadership in advanced aircraft structures by: Being always at the forefront of technology. Applying the most advanced structure technologies as a prime goal since the beginning of Airbus. Considering customer needs, performance, environment/health & safety aspects. Pushing new technologies, carefully evaluated and introduced step-by-step as soon as they are matured. Fostering the competition between different materials to exploit their physical potentials and enhance their performance. 4 Materials for airframes, the A380 and beyond Materials for airframes Strengths Metals (Al-alloys) Composites (CFRP) Fiber Metal Laminates 5 Materials for airframes, the A380 and beyond Weaknesses Broad experience Repairability Static behavior Improvement potential High density Fatigue behavior Corrosion behavior High costs of new alloys Fatigue behavior Low density No corrosion Best suited for smart structures Impact behavior No “plasticity” Repairability Recycling Improved fatigue Better “tailoring” Higher fire “resistance” Less corrosion (compared to Al-alloys) Lower stiffness Higher density Less industrialized process (compared to CFRP) What the airframe requires Upper skin: Compression/stability Lower skin: Tension/crack growth Longitudinal stress Static/residual strength Crack growth Bending and Torsion Impact Shear stress Bending Impact Hoop stress and longitudinal stress Shear stress due to transverse shear and torsion Impact Hoop stress 6 Impact Materials for airframes, the A380 and beyond High local loads Compression due to bending, stability, static strength, corrosion resistance Composites vs. metal: The benefit of competition 1980 1970 1990 2010 2000 2020 CFRP Wing Fuselage section Center wing box Pressure bulkhead Keel beam Floor panels CFRP design advanced Al casting VTP, HTP Flaps, Fairings Moveables, Rudder FSW, Al-Sc GLARE®, LBW, EBW, Ti alloys Al-Li Al-Li Metal design LBW, extrusions 7 Materials for airframes, the A380 and beyond CFRP Fuselage Adaptive Structures, SHM Successor GLARE® How Airbus airframes have evolved A320 A300/A310 GFRP fairings, radome, fin leading edges CFRP movables: spoilers, airbrakes, rudder CFRP primary structure: fin (A310-300) … CFRP primary structure: flaps, horizontal tailplane (HTP) Automated Tape laying Laser Beam Welding (LBW) (A318) A330/A340 … … CFRP primary structure: HTP as fuel tank CFRP primary structure: Center Wing Box, Rear fuselage, wing ribs CFRP primary structure: pressure bulkhead, keel beam, floor panels (A340-600) Resin infusion techniques Thermoplastic CFRP (A340-600) New Al-alloys 1974 (EIS) 8 Materials for airframes, the A380 and beyond A380 Higher modulus carbon fibers A400M … CFRP wing further airframe innovations … Upper fuselage: fiber metal laminate LBW, Electron Beam Welding Resin film infusion Automated fiber placement New Al-, Ti-alloys 2009 Airbus: The leader in CFRP technology CFRP structural weight % 35 30 A400M 25 A380 20 15 A340-600 10 A340-300 A320 5 A310/200 A300 0 1970 1975 1980 1985 1990 Year 9 Materials for airframes, the A380 and beyond 1995 2000 2005 2010 Airbus: The leader in metal technology Advanced metal technologies Laser Beam Welding (LBW) Stringer guiding system Beam guidance Stringer to skin LBW New Al-alloys: e.g. Al-Li New Ti-alloys Electron Beam Welding Friction Stir Welding Extrusions, Castings, … 10 Materials for airframes, the A380 and beyond Example: section 18, lower panel Airbus: The leader in fiber metal laminates (FML) Fiber metal laminates (FML) GLARE® application in A380 upper fuselage and D-noses (HTP, VTP) Composite material (GFRP) Aluminum material GLARE® Micrograph 500 µm High performance FML (e.g. improved static strength, improved stiffness) 11 Materials for airframes, the A380 and beyond Example: section 18, main deck panel A380: The most advanced airframe (examples) GLARE® CFRP Wing Ribs CFRP Floor Beams for Upper Deck CFRP Section 19.1 CFRP Section 19 More Ti & New Ti-processing (electron beam welding) Integral Structures (LBW) 12 Materials for airframes, the A380 and beyond CFRP Center Wing Box New horizon: The “intelligent” aircraft structure Further approaching the Superior Airframe Vision, Airbus is aiming at the “intelligent” structure: Best suited to local airframe needs, i.e. optimised hybrid design Self-monitoring and reacting Adaptable to changing requirements Highest tolerance towards external effects to enable: Leading edge of performance Minimum maintenance, extended operational life Highest possible environmental friendliness 13 Materials for airframes, the A380 and beyond Structure Health Monitoring – Aspect of Airbus “intelligent” airframe Human nervous system: The brain detects intensity and location of pain and judges when to go to the doctor. Evaluation SHM system: The SHM System checks the structure and evaluates the follow up actions for maintenance. SHM 1st Generation: Maintenance cost reduction, increased aircraft availability SHM 2nd and 3rd Generation: New design philosophy enabling weight reduction 14 Materials for airframes, the A380 and beyond “Intelligent” aircraft structure: more than SHM Self-Monitoring Adaptive Structure Self-Cleaning Nano-Materials Material Matched New Design Nanotechnology Sensors Synergy between fuselage and cabin interior Self-Healing 15 Materials for airframes, the A380 and beyond Future Airbus airframe technology Advanced composite & metallic materials New Composite material applications Optimized material matched design Composites adapted design 2st, 3rd Generation SHM Fiber Metal Laminates Nanotechnology: materials & sensors New metals and adapted design Composites primary & secondary structure 1st Generation Structural Health Monitoring Adaptive structures New material processes 1970 16 1990 Materials for airframes, the A380 and beyond 2010 2030 Airbus airframe vision High performance “Intelligent” airframe Conclusion Best materials and related technologies have been used/will be used in future in Airbus airframe for the specific application: THE BEST MATERIAL FOR THE SPECIFIC APPLICATION not ONE MATERIAL FOR ALL. The philosophy of best material use leads to a hybrid airframe adapted to the local specific requirements (mixture of different materials). The high performance “intelligent” Airbus airframe is: - optimized regarding new materials matched design - self-monitoring and reacting - adaptable to changing requirements The high performance “intelligent” Airbus airframe technology is introduced step-by-step after demonstrating maturity, securing the leading role of Airbus in airframe technology 17 Materials for airframes, the A380 and beyond