Electro coagulation treatment for textile waste

Xccelerated Coagulation

For

wastewater Treatment and Reuse

in

Textile Processing House

About KAASHPRA GLOBAL ENVIRO CARE

Water & Wastewater treatment technology focused venture.

Engaged in:

• Research and Development of Electrochemical process based water and wastewater solutions.

• Development of Low cost wastewater treatment & reuse solution for local industries.

• Development of Chemical free disinfection, sanitation and cleaning process for industries, hospitals, hotels and domestic applications.

Sector focus:

• Chemical, Pharmaceutical, Food processing, Textile, Metal processing and Dairy

• Medical and Hospitality industry

Problem with Textile Processing

Wastewater treatment System

• High volume of wastewater

• Very Scarce space available for inplant treatment

• Complex nature of wastewater with dyes and auxiliaries

• Biological treatment unable to handle organic and hydraulic loads

• Larger treatment plant based on biological system are not viable – from engineering and economic point

• Manpower is not readily available to handle conventional plants

About Xccelerated Coagulation

Xccelerated Coagulation treatment of Textile Wastewater

Tomorrow’s Technology Today

Conventional Process

1.

Conventional process includes 4 to 5 treatment steps: Primary, Filtration,

Secondary, Clarification, Tertiary

2.

Generates sludge at multiple points

3.

Cannot be made automatic

Electrochemical Process

1.

Single stage operation, two stages at maximum

2.

Generates sludge at single point

3.

Sludge volume is substantially low

4.

No additional chemicals

5.

Completely automatic

Case Studies

Treatment of wastewater from Textile

Processing house

(Right – Before treatment, Left –

After treatment), Initial COD: 800 ppm, Treated COD: <100 ppm

Treatment of wastewater from Textile

Processing house

(Right – Before treatment, Left – After treatment), complete removal of Turbidity

Treatment of wastewater from Textile

Processing house

Raw COD: 1908

Treated COD: 119

Appearance: Completely clear water

Treatment of wastewater from Textile

Processing house

Raw COD: 2544

Treated COD: 100

Appearance:

Completely clear water

Treatment of wastewater from Textile

Processing house

Raw COD: 2063

Treated COD: 636

Appearance: Very light tint yellow color

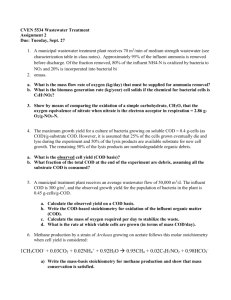

Results from on Field Trial in Textile

Processing house

Trials conducted at Textile processing house at

Various treatment flow rates:

Day 1

Sample Name

1

2

3

4

Day 2

Sample Name

1

2

3

4

Details

RAW

30000 – 40000 L/day

40000 – 50000 L/day

80000 – 90000 L/day

Details

RAW

40000 - 50000 L/day

60000 – 70000 L/day

90000 – 100000 L/day

COD

2000

400

340

200

COD

1200

400

250

190

Day 3

Sample Name

1

2

Details

RAW

100000

– 110000 L/day

COD

400

<150

Before

Before

After

After

Economics of Treatment

Economics of Xccelerated Coagulation

Treatment

Electrochemical System for

100 KL/day Textile house needs:

1. 3 to 4 sq m of Area (excluding

Filtration area)

2. 8 to 10 HP of total power source

3. Treatment cost varies between 8 to 12 Rs./1000 liter*

4. Capital cost in range of 10-12

Rs./Liter**

* - Approximate treatment cost

** - Filtration system under client scope

Unique advantages of

Treatment process

1. Lower Sludge Volume

2. 70-80% reduction in chemical use

3. Reusable water in high volume application like washing, rinsing etc.

4. Fully automatic

5. Negligible maintenance

6. Ease of capacity expansion

For more information and Trials at your processing house kaashpra@gmail.com

or

CALL ON 09426611055, 09898500972