Bild 1 - About VocTrainMaint

advertisement

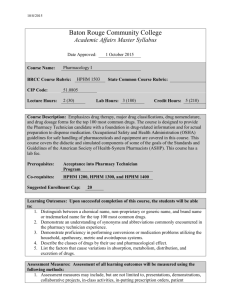

World Class Maintenance The project VocTrainMaint’s way to to develop a new education and training for the Practical Working Maintenance Technician to be a link in: World Class Maintenance World Class Maintenance The international development point out the needed way to understand World Class Maintenance World Class Maintenance The project objective is to form syllabi for three levels The syllabi are road maps to improved maintenance Advanced training Intermediate training Basic training Vocational teachers in Maintenance Maintenance Technician Electricians Multi skilled Mechanics World Class Maintenance World class Supporting maintenance systems Economy in maintenance Maintenance methods and supporting system Analytical techniques in maintenance Maintenance concepts and techniques Maintenance aims and strategies Goal: Understand the blocks in a maintenance management platform World Class Maintenance Go from basic to advanced maintenance in an cost effective process Train to understand and use advanced methods such as Reliability-cantered maintenance (RCM) is a process to ensure that assets continue to do what their users require in their present operating context 1.What is the item supposed to do and its associated performance standards? 2.In what ways can it fail to provide the required functions? 3.What are the events that cause each failure? 4.What happens when each failure occurs? 5.In what way does each failure matter? 6.What systematic task can be performed proactively to prevent, or to diminish to a satisfactory degree, the consequences of the failure? 7.What must be done if a suitable preventive task cannot be found? World Class Maintenance Lean Production require fully developed 5S and TPM Total Productive Maintenance (TPM) Three basic parts in TPM: - Collection of facts Were are the losses? What can we be better on? Understand! - Operators All persons working in the equipment have the responsibly to take care. - Improvements groups Work hard with the problem! All have responsibly to improve the process. World Class Maintenance Developing the new education and training in VocTrainMaint adapted for industrial needs Whit The way to reach World Class Maintenance as a base World Class Maintenance Practical working maintenance technician must understand the structure of production and role cast of maintenance Good combination of theoretical and practical subjects create needed platform for work in the future World Class Maintenance The education and training is based on measurable learning outcomes Project goal: LifeLong Learning starts in the school system The syllabi cover 46 subjects based on industrial requirements Courses can be runner separately in order to support employed personnel The courses are a perfect platform for Type Rating courses World Class Maintenance EU require transparency and recognition of competences and qualifications Our project develop national and sectoral qualifications systems adapted for - the Euro pass portfolio, - the ECVET system, and - the European Qualifications Framework (EQF) by using validation as quality assurance tool. World Class Maintenance Market needs New syllabi Multi skilled technician Basic Electrical trained Basic mechanical trained Practical oriented platform The market need individual adapted vocational education and training World Class Maintenance Important to understand the Strategy of Continuous Improvement and perfect working conditions We inform about S5 to S7 The important steps into cost effective maintenance Phases of 5S – S7 - Sorting (Seiri) - Straightening or Setting in Order / stabilize (Seiton) - Sweeping or Shining or Cleanliness / Systematic Cleaning (Seiso) - Standardizing (Seiketsu) - Sustaining the discipline Or Self Discipline (Shitsuke) - Safety World Class Maintenance Fault finding is the main objective for a practical working maintenance technician Trouble shouting require ”Logical thinking” Very good technical understanding concerning involved machinery Failure effect analysis (FEA) or Failure Modes and Effects Analysis (FMEA) Functional Failure Analysis (FFA) World Class Maintenance New body of courses Adding needed courses Test taker Validation Adapted training Approved competence Validation Form the labour force by mixing validation with education and training World Class Maintenance A good understanding of the maintenance role in the total production system is needed TPM = Total Productive Maintenance = Systematic work to trouble free production via workforce engagement. Lean Manufacturing A key factor for success is cost effective maintenance The five main elements of developing maintenance (Kaizen) - Teamwork - Personal discipline - Improved morale - Quality circles - Suggestions for improvement World Class Maintenance Economical understanding is important in maintenance The new maintenance syllabi cover the industrial needs of wide understanding Life cycle profit (LCP) Life cycle profit - reducing supply risks by integrated demand management Life cycle cost (LCC) Analyses of: Life cycle assessment, Whole life cost World Class Maintenance Go from basic to advanced maintenance in an cost effective process Open up for World Class Maintenance 7 step to act as a Maintenance Technician specialist 7. Increase the equipment lifetime to maximum probability 6. Use condition based maintenance (CBM) in big scale 5. Improve maintenance activity to good efficiency 4. Increase the time between maintenance activity 3. Form standards to keep the level 2. Improve the equipment condition 1. Follow up and analyse the difference between the equipments actual and purchased status.