Details of Machine Service Center Process

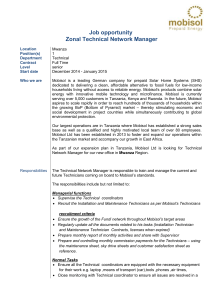

advertisement

SERVICE EXCILLENCE – VENDING MACHINES OUR MISSION Product Quality Customer Satisfaction Service Quality Uniform Branding OUR OBJECTIVE 1. Increase machine up time and reduce volume loss through machine breakdown by timely preventive maintenance. 2. Machine hygiene as per Unilever standards through proper Machine audit. 4. Reduction in technical expenditure – Manpower/Spare Cost 5. Costumer satisfaction by immediate call response through call centre. 5 One India - One Model, one sets of Spares – 100% Machine upkeep Customer satisfaction WAY OF WORKING The Machine is the Heart of our Vending Business Good Relationshi p with Client SAFETY Smooth Business Operation s Minimum Downtime for Machines ProfitablityUse of Spares at minimum Technician – Front Runner Of Company Customer Satisfactio n Quality & Hygiene Maintainability HIGHLIGHTS OF GTM • Asset coding for every machine. • Call centre stickers on each machines. • Route wise customer list for each technician for PM / BM • Select and trained technician • Draw up the beat plan to optimize the efficiency of the technician. • Proper dress code and Equipped technicians with tools, Measuring Instruments, Spares & Reports. • Review the mechanism on weekly basis and proper refresher training to each technician FORMATS TO DATA CAPTURING BM/PM sticker , filling by technician Work order format , filling by technician Call centre sticker CALL CENTRE Centralized Call Centre 18002003836 PROCESS FOR CALL REGISTRATION AT CALL CENTRE Call to call centre on toll free no 18002003836 Provide machine related information like machines asset no, customer name and address detail, breakdown detail to centre to registered the complaint Confirmation on customer mobile through SMS for call registration along with complaint num Machine Asset no Call forwarded to respective service provider through netsuite software Call centre sticker with machine asset no SERVICE CENTRE SERVICE STRUCTURE Service centre Route Supervisor-1 PM Technicians BM Technicians Route Supervisor-2 PM Technicians' Technician ratio 60mc/tech BM Technicians PROCESS FOR BREAKDOWN CALL Complaint received from Call centre through netsuite at service centre Call forwarded to respective area technician SMS received by customer with technician name and time SMS received by Technician with outlet detail and visit time Outlet visit by technician and attend the call Call completed Filling service report with work done and spare consumption detail Report verification by customer with seal and signature Customer is satisfied Call is fully closed in system Sms forwarded by technician to service centre for call completion SMS received by customer for call closing and feed back for call satisfaction through SMS reply Call partially closed in system Customer is not satisfied Call reopen in system for next visit and case escalated to next level PROCESS FOR PREVINTIVE MAINTENANCE Platinum account s Once in month Gold account s Once in month Silver accounts Once in month Bronze Once in two month • Technician wise Pre journey plan will be defined for each account netsuite • Reminder for next PM will be automatically generated through Netsuite • Report for all spares consumption and PM compliance / Non compliance will generated and circulated on monthly basis to respective person. PROCESS KPI’S • Timely preventive maintenance to each and every machine • Minimum call response/ call closer time (3-4 HRS) by immediate call response • Min spare cost/Maintenance cost by proper preventive maintenance • Update customer/machine master with machine installation/pullout detail • Machine hygiene as per Unilever standard through timely preventive maintenance and pest control • MIS generation for all activities like BM calls, PM calls, Spare consumption technicians efficiency etc THANK YOU Mandeep Trading Co