SCRAP TIRE MARKET DEVELOPMENT BY TERRY GRAY TAG

advertisement

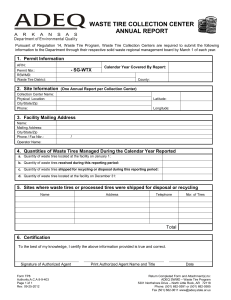

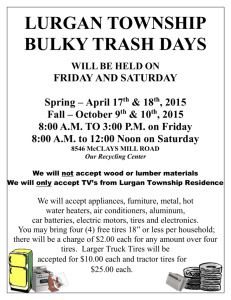

SCRAP TIRE MARKET DEVELOPMENT BY TERRY GRAY TAG RESOURCE RECOVERY TIRE WORKSHOP 2013 SAN ANTONIO, TEXAS APRIL 3, 2013 PERSPECTIVE FIRST PROGRAM IN MINNESOTA IN 1984 MANY U.S. STATES STILL DON’T HAVE SUCCESSFUL PROGRAMS <1% UTILIZED IN 1984, BUT ABOUT 80% IN 2011 MEXICO CAN ACCELERATE ITS GROWTH BASED ON GOOD AND BAD HISTORICAL EXPERIENCES US SCRAP TIRE MARKET TRENDS: 2005-2011 MAJOR APPLICATIONS ENERGY CEMENT KILNS POWER GENERATION PAPER MILLS DEDICATED FACILITIES PYROLYSIS/GASIFICATION U.S. TIRE-DERIVED FUEL MARKET TRENDS: 2005-2011 U.S. TIRE-DERIVED FUEL MARKETS 2011 CEMENT KILNS ENVIRONMENTALLY EXCELLENT ECONOMICALLY ATTRACTIVE QUICKLY DEVELOPED GENERALLY WHOLE TIRES, SOME TDF NEEDS CONSISTENT SOURCE PROGRAM CORNERSTONE MODERN CEMENT FACILITY CEMENT KILN MANUAL FEED SYSTEM AIR LOCK INTO KILN RAPID COMBUSTION POWER AND PAPER INDUSTRIES SPECIFIC BOILER TYPES INCLUDE CYCLONE, STOKER-FIRED, CFB DISPLACES COAL OR OTHER SOLID FUEL USES NOMINAL 1” OR 2” TDF, BEAD WIRE REMOVED COMPARATIVE TDF PRODUCTION ECONOMICS (CHIP SIZE VS TIRES/YR) CHIP SIZE 500,000 1,000,000 1,500,000 2.0” +69% -11% -42% 1.5” +82% BASIS -14% 1.0” +94% +35% 0% PYROLYSIS HISTORICALLY UNSUCCESSFUL • NO COMMERCIALLY SUCCESSFUL SYSTEMS IN NORTH AMERICA • OVER $500 MILLION EXPENDED • MAJOR COMPANIES AND SMALL PROMOTERS CRITICAL ISSUES TECHNICAL PERFORMANCE • UNRELIABLE OPERATION • EXPLOSIONS/FIRES • ENVIRONMENTAL ISSUES AIR CHAR DISPOSAL ECONOMIC PERFORMANCE • GAS UTILIZATION • OIL ONLY BLENDSTOCK • CHAR MARKET CIVIL ENGINEERING LIGHTWEIGHT FILL DRAINAGE AGGREGATE WHOLE TIRES IN RETAINING WALL CONSTRUCTION Dixon Landing Interchange PROBLEM: Embankment Constructed on Bay Mud SOLUTION: Use TDA for the core of the embankment CHEAPEST SOLUTION: Caltrans saved $470,000 Typical Cross Section LOW PERMEABILITY SOIL COVER TWO TIRE SHRED LAYERS EACH LAYER UP TO 10 FT THICK COMPRESSIBLE BAY MUD Spread with bulldozer Rt. 91 Wall in Riverside, CA Freeway widening Objective: show that reduced earth pressures can reduce overall wall construction costs Length: 260 ft Tires used: 75,000 PTE Rt. 91 wall cross section Half of TDA in Place Potential Future Savings for Walls Lower pressure on wall less rebar Potential reduction = 28 tons/100 ft Potential cost savings = $13,000/100 ft RETAINING WALLS WHOLE TIRES MECHANICALLY JOINED TO STABILIZE OR RETAIN SLOPE NOT BROADLY APPLIED IN US DUE TO LABOR COSTS MINIMAL CAPITAL EXPENSE FOR SMALL VOLUMES CRUMB RUBBER APPLICATIONS SPORTS SURFACES MOLDED PRODUCTS RUBBER-MODIFIED ASPHALT DECORATIVE MULCH CRUMB RUBBER CHARACTERISTICS SLOW OVERALL MARKET GROWTH HIGH CAPITAL HIGH MAINTENANCE MARKET CHALLENGES RURAL CONSIDERATIONS VOLUME SENSITIVITY REGIONAL PLANS, COLLECTION CENTERS OR PROCESSING FACILITIES MOBILE PROCESSING CAREFULLY EVALUATE BALE APPLICATIONS BEFORE STARTING SUGGESTIONS FOCUS ON ENERGY (ESPECIALLY CEMENT KILNS) INITIALLY DEVELOP CE DESIGN EXPERIENCES AND PRACTICES BEGIN TO ENCOURAGE CRUMB MARKETS, BUT AVOID PREMATURE OVER-COMMITMENT PROCESSING EQUIPMENT APPLICATIONS RANGE FROM WHOLE TIRES TO FINE POWDER SPECIFIC EQUIPMENT REQUIRED TO PRODUCE EACH SIZE PRODUCT KNOW MARKET BEFORE PURCHASING EQUIPMENT KEYS TO SUCCESS LEARN FROM OTHERS’ SUCCESS AND FAILURE EVALUATE BEFORE CHARGING CHALLENGE “MAGIC” PROPOSALS RECOGNIZE LOCAL MARKET VARIATIONS RECOGNIZE REALITY CONTACT INFORMATION TERRY GRAY TAG RESOURCE RECOVERY EMAIL: tagray@flash.net PHONE: (281) 463-7552