Hengwei Liu`s Presentation - Woodrow Wilson International Center

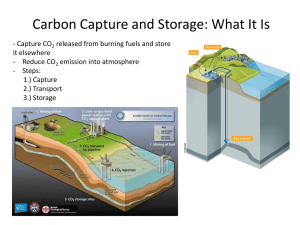

advertisement

Enhancing China’s Sustainable Growth and Prosperity: a Pathway to Cleaner Coal Hengwei LIU, PhD Energy, Climate, and Innovation (ECI) Program The Fletcher School, Tufts University Presentation to the China Environment Forum @ Woodrow Wilson International Center for Scholars, Washington, D.C., 12 January 2011 Agenda • Explore major CCS opportunities • Identify key technologies enabling CCS development • Propose a US-China partnership on CCS HengweiLiu, Kelly Sims Gallagher. Catalyzing strategic transformation to a low-carbon economy: A CCS roadmap for China. Energy Policy38(2010)59–74. CO2 emissions by sector in China 7% 9% 8% 7% 6% 8% Iron & steel Industry 28% 9% 7% 6% 11% Power (Cement) (Ammonia & Methanol) Power 7% 4% 10% 49% Total: 5100 Mt Industry 28% Industry 8% 6% 21% 4% Total: 11448 Mt (Reference Scenario) 10% 49% 2005 Power generation Other* Chemicals and petrochemicals 54% Transport Iron and steel Other** 2030 Residential and services Non-metallic minerals Power generation and industry account for more than 70% of China’s Total: 5100 Mt (2005) total energy-related CO2 emissions Data source: WEO2007 Prime candidates for CCS in China Power Iron and steel Today: more than 80% coal electricity Cement Ammonia & Methanol Data source: NBS CCS and its enabling technologies: a twin-pronged approach to promote the CCS deployment Manufacturing process & energy conversion process CCS enabling technologies + CCS Summary of CCS enabling technologies SC/USC Power Polygeneration (IGCC) IGCC/Co-production Leading technology Polygeneration based on Oxygen Blast furnace Iron&Steel Polygeneration based on Smelting Reduction Polygeneration based on Direct Reduction Ammonia &Methanol Coal gasification Cement Oxy-fuel combustion in cement kiln Coal gasification Coal power generation: IGCC &SC/USC •IGCC: Integrated Gasification Combined Cycle n io t n) a o r i t g a te c n i i sif m •SC / USC: Supercritical / Ultra-supercritical st y S e s a g n Sy IGCC Precombu a (G Postcombu Coal Pulverized coal (Combustion) SC/USC High temperature/pressure Large capacity Gasification & advanced combustion: roads to higher efficiency Oxy-fu combu Co-production: an important approach to promote IGCC development in China Air ASU N2 Combined Cycle O2 Coal Gasifier Syngas (CO+H2) IGCC Chemical plant Steam Electricity methanol Shift reactor CO2+H2 Separator CO2 H2 Other Power generation Fuel cell EOR/ECBM Sequestration Ocean storage Others (2) CCS enabling technologies: Iron & Steel SC/USC Power Polygeneration (IGCC) IGCC/Co-production Leading technology Polygeneration based on Oxygen Blast furnace Iron&Steel Polygeneration based on Smelting Reduction Polygeneration based on Direct Reduction Ammonia &Methanol Coal gasification Cement Oxy-fuel combustion in cement kiln Coal gasification Iron making: development trend Direct reduction Smelting reduction • Non-blast furnace iron-making • Blast furnace iron-making • Dominant technology • Severe pollution Breakthrough CCS enabling technologies are needed to achieve large-scale CO2 reduction Steel making Iron ore pelletizing Lime stone Sintering Rolling Iron ore Coking Washed coal 10% Blast furnace Converter 7% Bao Steel 10% 7% 21% 21% 2% 15% 2% 45% 15% 45% Sinter BF Coke making Converter EF Rolling Sinter BF Coke making Converter EF Rolling Capture from the main emitter (blast furnace) brings only about 30% reduction in CO2 emissions Data source: ZHANG Shourong Polygeneration based on Oxygen Blast Furnace Off Gas (CO+H2) Electricity Methanol Co-production units Oxygen Blast Furnace The off gas with medium heating value from OBF is used as an IGCC/co-production fuel gas Steel Converter Picture from internet Polygeneration Based on Direct Reduction Electricity Methanol Co-production Syngas CO+H2 units Gasifier Steel By coupling IGCC/co-production with a DR process, it shares one gasifier to produce syngas Direct Reduction Unit Electric Arc Furnace Picture from internet Polygeneration based on Smelting Reduction Off Gas (CO+H2) Electricity Methanol Co-production units Smelting Reduction Unit The off gas from SR is used as an IGCC/co-production fuel gas Steel Converter Picture from internet (3) CCS enabling technologies: Ammonia & Methanol SC/USC Power Polygeneration (IGCC) IGCC/Co-production Leading technology Polygeneration based on Oxygen Blast furnace Iron&Steel Polygeneration based on Smelting Reduction Polygeneration based on Direct Reduction Ammonia &Methanol Coal gasification Cement Oxy-fuel combustion in cement kiln Coal gasification Ammonia & Methanol Ammonia Syngas Gasification coal Methanol • • Ammonia industry is the largest consumer of gasification technology in China. Coal-based synthetic ammonia accounts for about 75% of total output – Consume 50 Mt coal per year coal-based methanol accounted for about 80% of total output. – consume about 12 Mt coal Pathway to a low-carbon future CCS •Polygeneration • Polygeneration •Coal gasification Today~2020 (power-chemicals-steel) (power-chemicals & power-steel) 2020~2030 Integration & Optimization 2030~ Cleaner coal & water 7 6 5 4 Without capture With capture 3 2 1 0 Subcritical USC Water consumption (Kg/MWh) Subcritical: 300MW; USC: 1000MW; IGCC: Gasifier: Shell Estimated by Hengwei Liu IGCC How to use coal in a carbon-constrained future? Syngas to liquids +CCS (Gasoline, diesel) Syngas to chemicals (Methanol, ammonia, etc.) Gasifier Gasification Coal +CCS Syngas Syngas to power +CCS (IGCC/polygeneration) Advanced combustion Syngas for iron-making (Direct reduction) +CCS USC/SC + CCS Energy & water efficient approaches to a cleaner coal: advanced combustion & gasification Who owns our low-carbon future? Geographical location of the parent companies of patent owners International cooperation is critical for CCS diffusion Source: Bernice Lee, Ilian Iliev and Felix Preston. Chatham House Report 2009 Accelerating technology diffusion and drive down the cost of CCS through a U.S.-China partnership • US has a more advanced S&T innovative system and has a well established regime for bringing technologies to market. • China has vibrant market, and the ability to commercialize new technologies more quickly and cheaply. USA 19% Other 33% China 43% India 7% ROW 59% China 22% USA 17% Total: 3303.7 Mtoe Coal Consumption by Country (2008) CO2 emission: China+USA=41% Data source: IEA&NBS Conclusions • A twin-pronged strategy for CCS and its enabling technologies should be developed. • Coal gasification & advanced combustion are energy & water efficient ways to a cleaner coal, and they should be given top priority to enable CCS development in China. • A U.S.-China partnership has the potential to accelerate technology diffusion and drive down the cost of CCS. Thank you! Hengwei Liu (刘恒伟) http://hengweiliu.weebly.com/ Email:hengwei_liu@hks.harvard.edu liu.ccs@gmail.com