XIAMEN G&P ELECTRONICS CO.,LTD.

advertisement

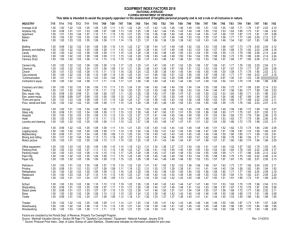

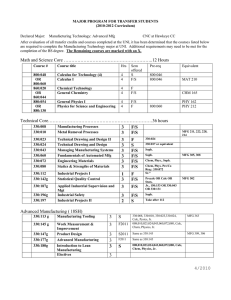

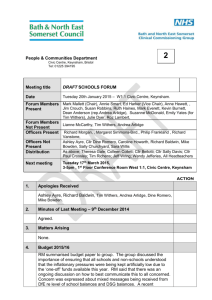

Company Profile XIAMEN G&P ELECTRONICS CO., LTD. Jiayi Industrial Park, Huli District Xiamen, Fujian province, China 361006 TEL:+86-592-6110703 FAX:+86-592-5700318 E-mail: xmfpc@globalsources.com http://www.globalsources.com/xmgp.co Content of Profile Company Information Major Customer MFG Process MFG Capability MFG & Test Equipment Company Information Xiamen G & P Electronics Co. Ltd specializing in the developing, manufacturing and marketing of flexible PCB. With advanced equipments and skilled workers, we produce 30,000 m2 FPC monthly at our ISO 9001-certificated factory in Xiamen. Each of our products is made of top-grade materials and compliant with the RoHS directives. Some well-known buyers such as Amoi Mobile and AOC source FPC from us because of our competitive price, reliable quality and prompt delivery. Our greatest advantage over our competitors is our engineers. All of them is well trained and experienced. Currently they are focusing on improving technology, reducing cost and defect rate to meet a higher market standard. Just let our professional engineers work on your OEM/ODM orders. Company Information : 5000 Square Meter Factory area : 375 Employees R & D engineers : 20 2/month : 20,000-30,000 m Capacity Product Introduction Advantage Application Note-Book Small Size Digital Camera DVD / CD-ROM Light Weight Flex-for-Installation Dynamic Flexibility HDD Printer Scanner PDA Cellular Phone LCD Auto-Mobile Our Customers Mobile LCD OR LCM MFG Process Major Equipment(1) NC Drilling Exposuring Room Major Equipment(2) D.E.S. Major Equipment(3) CVL Lamination Hole-Punching Major Equipment(4) Screen Printing Elec.-test & Visual Inspection Major Equipment(5) Blanking Quality Assurance System Incoming QC Strict quality control and inspection are done at each stage of producing 100% of In-process QC and Final inspection Testing is carried out within three lab: chemical, physical and electric-test Weekly quality report with statistical information Prompt responses and feasible solution to customer‘s quality complaint. MFG & Test Equipment(1) 2-D Measuremen System Peel Strength Testing Machine MFG & Test Equipment(2) Swaying Test Machine Micro Scope MFG & Test Equipment(3) Slice up Muller X-ray Thickness Measurement Process Capability General Number of layer: 1-6 Copper Foil: 1/3, 1/2, 1.0, 2.0 oz Material: Polyimide (Kapton), PET, FR4 Min. conductor width/spacing: 0.075 mm Min. hold diameter: Drilling:0.20 mm Punching: 0.50 mm Special Material Available: Halogen Free 2 mil PI Tolerance Conductor width: + / - 0.03mm Hole diameter: + / - 0.05mm Accumulated pitch: + / - 0.05mm Outline dimension: + / - 0.05mm Surface Treatment Electrolytic Tin ( Lead free) Plating Hot Air Leveling Electrolytic Nickel and Gold Plating Eelectroless Nickel and Immersion Gold Plating Honor Certificate (UL:E230743) 2002 passedISO9001:2000 RoHS Approval by SGS report 2002 passed UL