Danaher Drives Presentation

advertisement

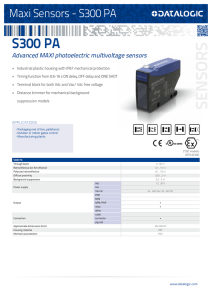

AHTD Symposium - Drives April 4-5, 2006 Jill Mattson Lou Lambruschi Siegfried Fischer Overview • Review Business • Drives Commitment • Review Push Products • Key Features • What’s New • Issues/Actions • Drive Selection • Introduce Fusion Drive Title, Author, Date 2 Danaher Motion is Committed to Drives • Building Product Line Management Team • Project Managers for Drives • Engineering Support Team • Focus on NA Market Needs • New products / line extensions • Reduced lead-times on push products • Next Generation Drive development underway Title, Author, Date 3 S200 Drive Title, Author, Date 4 S200 Drive • Review Key Product Features • Where we have won and why • Present Business State • Where we are heading Title, Author, Date 5 S200: Key Features • Highest Servo loop bandwidth •High resolution (24bit) feedback •Current loop (3-5KHz BW) (1.25MHz update rate) •Velocity loop (800Hz BW) (1.25MHz update rate) Title, Author, Date • New Standards in Easy-to-Use • New Standards in Quality Level • Extremely aggressive price 6 S200 Where We Have Won • Semi EA • Robotics • Labeling • Packaging Industry • General Automation Title, Author, Date 7 Why We Win….. • Price • Allows competition with steppers • Small Size • Integrates well into Desk-Top Equipment • Flexible Command Modes • Pulse and Direction or Analog Input • Low Voltage Model • Safer Table-Top machines • High Bandwidth • Better Machine Throughput Title, Author, Date 8 Still to come…… Expanding the Family • Expanding Power Ranges • 6 Amp Program well under way • 12A, 24A, 48A Product program in-process • Operation with Multiple Feedback types • SynqNet Option adds Support • Sine Encoder • ComCoder • Endat 2.1 • Profile Generator with • Can or DeviceNet • and support Incremental encoder Title, Author, Date 9 S200 Summary Points • Leader in performance and quality • Strong value sale • We are investing to expand the family Title, Author, Date 10 S300 Drive Title, Author, Date 11 Strong points – Servostar 300 • Broad Voltage range, US and Europe • 115V - 230V (10A) • 230V - 480V (6A) • Built-in EMC filters for Europe • Rugged all metal enclosure • High level of protection • Certifications for different markets • CE mark, UL/cUL listing • Global acceptance Title, Author, Date 12 S300, small dimensions • Dimensions 242mm (h) x 171mm (d) x 70mm (w) • 115/240 VAC (3, 6, 10 amp) < 200 mm incl. connectors • 400/480 VAC (1.5, 3, 6 amp) < 230 mm incl. connectors Title, Author, Date 13 Strong points – Servostar 300 • Higher dynamic with DDL • DDL Motor Compatibility with FW 2.0 • High performance servo loops • Competitive Package with AKM • High Flexibility in Design • Communication • Feedback • For every application • Easy to use GUI => Motor turns with 8 Klicks Title, Author, Date 14 SERVOSTAR® 300, Bus Communication Title, Author, Date 15 SERVOSTAR® 300, Feedback Systems Open for • Resolver • Comcoder • Incremental encoder + Hallsensors • Endat • HyperfaceDigital • BiSS ® Title, Author, Date 16 Servostar Success Story • Metal Forming / Die Cast Machinery • Displaced Allen-Bradley & AMC HMI – Drive (S300) – Motor (AKM) • Key requirements of the motion system is: • 115/230/480 VAC small package with positioning • Field bus capabilities (Device-net) • High temperature performance (Tested at full load, 70 deg C lasted over a week – three times Yaskawa & Rockwell) Title, Author, Date 17 Servostar Success Story • Postal Handling Equipment (Sorters) • Displaced Allen-Bradley & Siemens Drive (S300) – Motor (Goldline XT) • Key requirements of the motion system is: • 480 VAC small package with positioning • Feed forward with Observer for rapid settling (small incremental moves) • Fixed FW and Parameter file upon shipping (maintained in production) Title, Author, Date 18 Servostar Success Story • Press Feed Machinery • Displaced AMC & PacSci Drive (S300) – Motor (AKM) • Key requirements of the motion system is: • 230/480 VAC small package with positioning • Rapid Indexing (45 deg move) with 14 msec duration to settling • Flex FW and Option Slot available for custom control card Title, Author, Date 19 Servostar Success Story • Tire Uniformity & Balancing Machinery • Displaced Indramat & Allen-Bradley Drive (S300 & S600) – Motor (BMS, AKM, XT) • Key requirements of the motion system is: • • • • Title, Author, Date Absolute Sine feedback (Auto Setup & Home) S600 CANOpen (S300 soon) communication as 16-24 axis per machine Position capability in the drive (PC as Master Control) Global sourcing and support 20 Servostar Success Story • Window production Machinery • Displaced Allen-Bradley Drive (S300) – Motor (AKM) • Key requirements of the motion system are: • 120/240/480 VAC supply on common platform • Field Bus capability (SERCOS) • Positioning capability (Linked moves) Title, Author, Date 21 Servostar Success Story • Cutter for cheese and meat (Food & Beverage) • Displaced Indramat Drive (S600) • Key requirements of the motion system are: • Field Bus capability (CanOpen, Profibus, SERCOS) • Positioning capability (Linked moves) Title, Author, Date 22 Servostar Success Story • Optical machines • Turning lathe for lenses • Displaced Siemens Drive (S300) • Key requirements of the motion system are: • CanOpen onboard, Sercos • Absolute High end Drive performance • Feed forward with Observer Title, Author, Date 23 Servostar Success Story • Book binding machines • Displaced Bosch Rexroth Drive (S300 & S600) • Key requirements of the motion system are: • Sercos • Drive performance • Robust and reliable drive Title, Author, Date 24 ServoStar Success Story • Bonder, Pick and Place applications in • Semiconductor and Electronic Assembly • Drive (S300 & S600) – Motor (AKM) • Key requirements of the motion system are: • CanOpen onboard, Sercos • Drive performance • Positioning capability Title, Author, Date 25 Servostar Success Story • Brought worldwide Industrial Market • Displaced Yaskawa, Mitsubishi and • internal drives from Berger Lahr and Elau • Brandlable Drive (S300+S600) – Motor (AKM) • Key requirements of the motion system are: • Flexible option slot for customized option cards like FIPIO, Modbus Plus, Motion • CanOpen onboard, Sercos • Drive performance and Positioning capability, Motion task Title, Author, Date 26 Servostar Success Story • Electro-Mechanical Assembly Presses • Displaced CT • Brandlable Drive (S300+S600) – Motor (AKM) • Key requirements of the motion system are: • Flexible option slot customized option board • Easy to brand label drive Title, Author, Date 27 Project Objectives S320 Product extension of S300 up to 24A • Range 12A • Range 24A • Prepared drive for Safety (Power ratings 1,5A, 3A and 6A are derived from 12A drive by derating) Scope • Common architecture to existing S300 • S300 processor and GUI • Replace S600 and cut maintenance cost Dimensions 12A (planned) • H = 277 mm • W = 70 mm • D = 240 mm CAD-Simulation Title, Author, Date 28 Which Drive to Choose? Technical Factors • Supply Voltage • Output Current • Physical Size • I/O Capabilities • Network Connection S600 S300 S200 • Field Bus • Motion Bus • • • • Experience with Application Motor/Feedback Support Store Motion Profiles Others S200 CNS Smart Drive Title, Author, Date CD 29 Which Drive to Choose? Category Torque Velocity Function Position S200 S200 CNS S300 S600 CD Smart Drive Step/dir only Available Soon Available Soon Available Soon Available Soon Indexing Programmable Interface Analog (+/- 10V) Motion Profile Step/Direction Encoder SynqNet Available Soon Ethercat SERCOS Modbus Point to Point RS-232 (ASCII) RS-485 (ASCII) Modbus Profibus limited DeviceNet CAN Open Discrete I/O Title, Author, Date 30 Which Drive to Choose? Category S200 DC input only (range) 20-90Vdc, 3/9A, 6/18A 115Vac 1.5/4.5A, 3/9A (Acont/Apeak) Power (output) 208/230Vac (Acont/Apeak) 480Vac Regen Sharing 1.5/4.5A, 3/9A Current rating Power (output) (peak/RMS) Future Current rating (continous/RMS) Title, Author, Date S200 CNS S300 S600 CD Smart Drive 20-90Vdc, 3/9A, 6/18A 1.5/4.5A, 3/9A 1.5/4.5A, 3/9A 6 through 48A (Future) 6 through 48A (Future) 18 to 96 (Future) 18 to 96 (Future) 3/9A, 6/18A, 10/20A 1.8/5.3A, 3.5/10.6A, 7.1/21.2A 3/9A 1.5/4.5A, 3/7.5aA, 6/12A 3/6A, 6/12A, 10/20A, 10/30A, 14/28A, 20/40A, 40/80, 70/140A 3/6A, 6/12A, 10/20A, 10/30A, 14/28A, 20/40A, 40/80, 70/140A 1.5/4.5A, 3/7.5A, 3/9A, 6/12A, 10/20A, 6/15A 2.1/4.2A, 3.9/7.8A, 6.4/12.7A, 3/9A, 6/18A, 10/20A 9.5/19.1A, 12.7/25.5A, 19.4/38.9A, 25.8/51/6A, 38.9/77.8A Replacement Drive 12 and 24 amps 2.1/4.2A, 3.9/7.8A, 6.4/12.7A, 9.5/19.1A, 12.7/25.5A, 19.4/38.9A, 25.8/51/6A, 38.9/77.8A Higher Currents 31 Which Drive to Choose? Category Size I/O S200 Depth (in) 5.2 (AC)/DC Mount area, height x AC 6.9x2.2in/DC with (in-in) Form factor (book or brick) 6x1.13in book Analog In / Out 1/2 Digital In / Out 5/2 Extended I/O S200 CNS 5.2 (AC)/DC AC 6.9x2.2in/DC 6x1.13in book 1/2 10 / 3 Brake Out Encoder In / Out Optical isolation Title, Author, Date (OUT ONLY) S300 S600 CD Smart Drive 6.7 11.2 (3-20) 12.8(40 & 70) 9.7x2.8 book 2/0 4/2 14 / 8 30(3-10A)/42 (14A)/51(20A) 134(40 & 70A) book 2/2 4/2 14 / 8 9.5 x 2.6 (3A), 9.5 x 3.5 (6A), 9.5 x brick 3.9 (10A) 1/1 6/1 6.12 (115/230 Volt) 8.35 (230/460) 11.4 (230/460) 11.4 (230/460) 8.8 x 6.12 (115/230 Volt) 13.2 x 4.2 (230/460 VAC) 16.1 x 4.2 (230/460 VAC) 21.3 x 6.1(230/460 VAC) book 1/0 16/12 6.4 32 Which Drive to Choose? Category S200 S200 CNS S300 S600 CD Smart Drive Resolver Feedback Supported Incremental Encoder Absolute Encoder (Endat) Stegmann SynqNet Only SynqNet Only SynqNet Only Medium Medium Very High Very High High Medium Indexing Limited Limited Limited Language Configure Motion Table Configure Motion Table Configure Motion Table Motion Commands Ladder and FB Comcoder SFD Hall sensors Sine Encoder Configuring Flexibility Gearing Camming Registration Positioning limited PLC functions Title, Author, Date (GMT) 33 Which Drive to Choose? Category AKM Push Motor DDR Compatibility DDL Title, Author, Date S200 S200 CNS S300 S600 CD Smart Drive limited - SFD/halls limited SFD/Comcoder 34 P7000 Microstepping Drives • Quick Update • P7000 AC • P7000DC Title, Author, Date 35 P7000 DC • Major Redesign • Smaller Size • Less parts Title, Author, Date 36 P7000 Value Proposition • Available as Step and Direction or with Position Control • S-300-Like Motion Tasking may eliminate a host controller • Adjustable Microstep to 25,600 Steps per revolution • Smooth ‘servo-motor like’ performance Title, Author, Date 37 P7000 Value • Motor Wave Shaping and Mid-Band Anti-resonance Tuning • Allows quieter operation and extends mechanical life • Dynamic Smoothing • Reduces system jerk for extended life and smoother motion Title, Author, Date 38 P7000 Value • Can be configured via dip switches without GUI • Faster, repeatable Setup • Small footprint and right price • Competitive market position • Possibility for Encoder-less Stall Detect • Pacific Scientific • step motors •T NEMA 23 •N,K NEMA 34 & 42 Title, Author, Date 39 What You Can Expect from Kollmorgen Drives • Leading Edge Performance • Quality Design • Investment in Development of Products, Technology and Organization • Growth focus Title, Author, Date 40