DS-S300PA-ENA4 (, 690953 byte)

advertisement

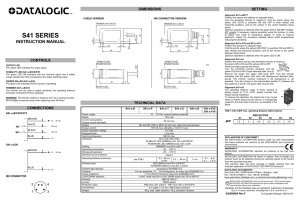

Maxi Sensors - S300 PA SENSORS S300 PA Advanced MAXI photoelectric multivoltage sensors • Industrial plastic housing with IP67 mechanical protection • Timing function from 0.6-16 s ON delay, OFF delay and ONE SHOT • Terminal block for both Vdc and Vac/ Vdc free voltage • Distance trimmer for mechanical background suppression models APPLICATIONS -Packaging end of line, palletizers -Outdoor or indoor gates control -Manufacturing plants (*) (*)DC models: ATEX II 3DG S300 PA Through beam 0…50 m Retroreflective (on R2 reflector) 0,1…15 m Polarized retroreflective 0,1…10 m Diffuse proximity 0,05...2 m Background suppression 0,2...2 m Vdc Power supply 12…30 V Vac Vac/dc 24…240 Vac/24…60 Vdc PNP NPN Output NPN/PNP • relay • other cable Connection connector • pig-tail Approximate dimensions (mm) 25x100x70 Housing material PBT Mechanical protection IP67 www.datalogic.com Maxi Sensors - S300 PA TECHNICAL DATA 12 … 30 Vdc (mod. S300…2) 24…240 Vac/24…60 Vdc (mod. S300…1) Power supply Ripple 10% max. 35 mA max. (mod. S300…2) 3 VA max. (mod. S300…1) Consumption (output current excluded) red LED 660 nm (mod. S300…B) IR LED 940 nm (mod. S300…C) IR LED 880 nm (mod. S300…A/G/M) Light emission sensitivity trimmer (mod. S300…A/B/C/F), DARK/LIGHT dip-switch (mod. S300…A/B/C/F/M) 7-turns distance adjustment trimmer (mod. S300…M) dip-switch mode ON delay/OFF delay/ON-OFF delay/single pulse (ONE-SHOT) (mod. S300…x06) timing trimmer (mod. S300…x06) Setting yellow OUTPUT LED (excl. mod. S300...G) green STABILITY LED, POWER LED (mod. S300...G) Indicators Output PNP or NPN open collector (mod. S300…2); electromechanical SPDT 250 Vac/30 Vdc (mod. S300…1) 100 mA (mod. S300…2) 3 A max. (mod. S300…1) Output current Saturation voltage Response time S300…1Switching frequency A/B/C/F/M 01 S300…1Connection Dielectric strengthA/B/C/F/M 01 Insulating resistance CONNECTIONS 2,4 V max. 1 ms (mod. S300..2-A/B/C/M) 2 ms (mod. S300…2-F/G) 25 ms (mod. S300…1) S300…1-G S300…2S300…2-G 500 Hz (mod. S300..2-A/B/C/M) CONNECTIONS 250 Hz (mod. S300…2-F/G) A/B/C/F/M 01 20 Hz max. (mod. S300…1) S300…1-G S300…2- terminal block S300…2-G A/B/C/F/M 500 Vac, 1 min 01 between electronics and housing >20 MΩ, 500 Vdc between electronics and housing Electrical protection class 2 (mod. S300…2) Mechanical protection IP67 (IEC/EN60529) Ambient light rejection according to EN 60947-5-2 Vibrations 0,5 mm amplitude, 10 … 55 Hz frequency, for every axis (EN60068-2-6) Shock resistance 11 ms (30 G) 6 shock for every axis (EN60068-2-27) Housing material PBT 30% glass fiber-reiforced Lens material frontal window and lens in PC Operating temperature Storage temperature Weight DIMENSIONS -25 … 55 °C -25 … 70 °C DIMENSIONS 120 g (mod. S300…2), 130 g (mod. S300…1) DIMENSIONS SETTINGS www.datalogic.com S300…A and S300…B setting Position the sensor and reflector on opposite sides. Turn the sensitivity trimmer to maximum. Find the points where the yellow LED (OUT) in both vertical and horizontal positions and fix the sensor SETTINGS Maxi Sensors - S300 PA CONNECTIONS ATA CONNECTIONS CONNECTIONS CONNECTIONS CONNECTIONS CONNECTIONS VAC MODELS VDC MODELS S300…1S300…1-G S300…2S300…1S300…1-G S300…2S300…2-G S300…1S300…1-G S300…2S300…2-G S300…2-x01 / S300…2-x06 S300…1S300…1-G S300…2-G S300…2-x01 / S300…2-x06 0…2-x01 / S300…2-x06 S300…1S300…1-G S300…2-S300…2S300…2-G …2-x06 A/B/C/F/M 01 A/B/C/F/M A/B/C/F/M 01 A/B/C/F/M 01 01 A/B/C/F/M 01 A/B/C/F/M 01 Through beam emitter Through beam emitter 12…30 A/B/C/F/M 01 2 (UL508) A/B/C/F/M A/B/C/F/M 01 A/B/C/F/M 01 VDC Class 01 12…30 Class 2 (UL508) …30 VDC ClassVDC 2 (UL508) UL508) 10% max.10% max. 10% max. < 35 mA < 35 mA < 35 mA S300…2-G PNP / NPN open collectorPNP / NPN open collector PNP / NPN open collector ector 100 mA load) (resistive load) 100 mA (resistive load) 100 mA (resistive ad) < 2.4 V max < 2.4 V max < 2.4 V max TEST+ input (S300…G) TEST+ input (S300…G) TEST+ input (S300…G) …G) ms(S300…F/G) (S300…A/B/C/M); 2 ms (S300…F/G) 1 ms (S300…A/B/C/M); 21ms 00…A/B/C/M); 2 ms (S300…F/G) (S300…F/G) G) 500 Hz (S300…A/B/C/M) 500 Hz (S300…A/B/C/M) 500 Hz (S300…A/B/C/M) DIMENSIONS C/M) DIMENSIONS 250 Hz (S300…F/G) 250 Hz (S300…F/G) 250 Hz (S300…F/G) DIMENSIONS DIMENSIONS DIMENSIONS G) 120 G. 120 G. 120 G. 300…B ; INFRARED (940nm) S300…C nm) S300…C …C RED (880 nm) S300…A/G/M G/M S300...B: …10 …10 m 2) on/R5 reflector (EG 2) m on R5 reflector (EG 2) ntor R5(EG reflector (EG 2) 0.1 target (EG 2)White /on S300...M: 20 … 200 cm on 90% White target 20 cm 90% White target cm… on200 90% target rget INDICATORS AND SETTINGS 00…F/G: 0 … 50 m (EG 2) SETTINGS ) YELLOW) / STABILITY LED (GREEN) ED (GREEN) EN) R ON LED (GREEN) S300…G 0…G The M model presents a multiturn adjustment B/C/F), DARK/LIGHT dip-switch (S300…A/B/C/F/M) screw for the adjustment of the background switch (S300…A/B/C/F/M) 300…A/B/C/F/M) nce adjustment trimmer (S300…M) suppression distance using a mechanical variation S300…M) of the optic triangulation angle. The other models ay / ON-OFF delay / Single pulse (ONE-SHOT) (S300…x06) eNE-SHOT) pulse (ONE-SHOT) (S300…x06) (S300…x06) x06)(S300…x06 esclude S300...G) have a mono-turn electronic trimmer that adjusts mer S300...G) the sensitivity and the sensor operating distance. 16 s (adjustment by Trimmer) mer) The operating distance can be increased by -25 … 55 °C rotating the screws clockwise. -25 … 70 °C Trimmers can be used to adjust the 1ing min housing between electronics and housing and output activation and deactivation VDC between electronics and housing and housing delay time whilst functioning mode selection is ng cording to EN 60947-5-2 performed through DIP SWITCHES. Hz (EN60068-2-6) frequency, for every axis (EN60068-2-6) ry55axis N60068-2-6) shock for every axis (EN60068-2-27) 60068-2-27) 7) Td30% Glass fiber-reiforced Ctal window and lens in PC SETTINGS SETTINGS IP67 (IEC / EN60529) SETTINGS SETTINGS SETTINGS er (CU) conductor and wire size No. 24-20 AWG, stranded or solid. re size No. 24-20 AWG,or stranded S300…A and S300…B setting . 24-20 AWG, stranded solid. or solid. S300…A and S300…B setting S300…A and S300…B setting ed or solid. S300…A S300…B setting minal tightening torque of 0.5 and Nm. Position the sensor and reflector on opposite sides. the sensitivity trimmer to maximum. S300…A S300…Band setting 0.5 Nm. the sensor on opposite sides. Turn thetrimmer sensitivity trimmer toTurn maximum. Position thePosition sensor and reflectorand on reflector opposite sides. Turn the sensitivity to maximum. Position the sensor and reflector on opposite sides. Turn the sensitivity trimmer towhere maximum. Find points yellow LED (OUT)and inpositions both vertical and horizontal connected toclass a Class 2 transformer orand class 2 power supply. the sensor reflector on opposite Turn sensitivity trimmer to maximum. Find thethe points whereLED the yellow LED (OUT) in both vertical and horizontal and fix the sensor positions and fix the sens ansformer 2 Position power supply. Find thesides. points where the yellow (OUT) inthe both vertical andthe horizontal positions fix the sensor or class 2 or power supply. Find the points where the yellow LED (OUT) in both vertical and horizontal positions and fix the sensor ply. in the centre these points. operation is obtained Find the points whereorthe yellow LED (OUT) in both vertical and positions and fixbetween the sensor ower-supply system,including filters air-gaps, overvoltage category II horizontal inbetween the centre between points. Optimum operation is obtained when switch both LEDs ON. when both LEDs switch ON. in the centre these points.these Optimum operation is obtained when bothOptimum LEDs ON. switch cluding filters or orof air-gaps, of overvoltage category IIof ers or air-gaps, overvoltage category II in the centre between these points. Optimum operation is obtained when both LEDs switch ON. If necessary, reduce sensitivity using the trimmer, in order to detect very small targets. centre DIAGRAMS between at these points. Optimum operation is obtained when both switch ON. to detect ervoltage category II in the over-voltages tegory IIsuitable If necessary, reduce sensitivity using the trimmer, in order to small detecttargets. very small targets. If necessary, reduce sensitivity using theLEDs trimmer, in order very rmer”), tothe control the maximum “rated impulse withstand over-voltages atDETECTION maximum “rated impulse withstand ges at the maximum impulse withstand Ifreduce necessary, reduce sensitivity usingin the trimmer, in order tosmall detect small targets. alignment, repeat the procedure detailed above whilst progressively reducing t In very order totheimprove If“rated necessary, sensitivity using the trimmer, order to detect very targets. “rated impulse withstand order to improve alignment, repeat procedure detailed whilst progressively In order to In improve alignment, repeat the procedure detailed above whilstabove progressively reducing thereducing the lse withstand nd with a short-circuit power limit at max 500VA. er limit at max 500VA. In orderalignment, to improverepeat alignment, repeat the procedure detailed whilst progressively max 500VA. sensitivity. In order to improve the procedure detailed above whilst above progressively reducing the reducing the sensitivity. sensitivity. “CONNECTIONS” paragraph raph sensitivity. sensitivity. S300...C setting S300...C setting S300...C setting S300...C setting theatsensor andatturn the sensitivity trimmer at minimum: yellow LED is OFF (litgh mod S300...C setting the sensor turn Position thetrimmer sensitivity trimmer minimum: the yellow LED is mode). OFF (litgh the mode). Position thePosition sensor and turn theand sensitivity minimum: the yellow LED is OFF (litgh IAGRAM (S300…x06) Positionand theturn sensor turn the sensitivity trimmer at minimum: the isyellow LED opposite is OFF (litgh mode). Turn the sensitivity trimmer clockwise until the yellow LED tur x06) Place target thetrimmer sensor. Position the sensor the and sensitivity trimmer atopposite minimum: the yellow LED OFF (litgh mode). Place the target the sensor. Turn thetrimmer sensitivity clockwise until LED the yellow Place the target theopposite sensor. Turn the the sensitivity clockwise until the yellow turns LED turns R2 Place the target the sensor. Turn the sensitivity trimmer clockwise until the yellow LED turns ON (Target detected state,LED pos.A). Remove the target, the yellow LED turns OFF. Turn the trimm Place the target opposite the opposite sensor.ON Turn the sensitivity trimmer clockwise until the yellow LED ON (Target detected state, pos.A). the turns target, the yellow LED turns OFF. Turn the trimmer (Target detected state, pos.A). Remove theRemove target, the yellow turns OFF. Turn the trimmer ON (Target detected state, pos.A). Remove theyellow target,LED the turns yellow LED turns OFF. Turn the trimmer clockwise until the yellow LED turnsstate, ON detectedreaches state, pos.B). The trimmer reach detected state, pos.A). Remove target, OFF. the trimmer R2 The LIGHT INPUT clockwise until LED the yellow LED turnsTurn ON (Background detected pos.B). trimmer clockwisetheuntil the the yellow turns ON (Background detected state, pos.B). The(Background trimmer reaches clockwise untilLED the turns yellowON LED turns ON (Background detected state, pos.B). The trimmerisreaches maximum if the background notindetected. the trimmer in intermediate position C, between t clockwise until the yellow (Background detected pos.B). The trimmer reaches R5 background R5 the if the is not detected. Turn the trimmer intermediate C, maximum ifmaximum the background isstate, not detected. Turn the trimmer in intermediate positionTurn C, position between thebetween maximum if the isbackground is not detected. Turn inthe trimmer intwo intermediate position C, the must be ON. positions A and B.the Thebetween green LED maximum if the background not detected. Turn theand trimmer intermediate position C, between two positions A green and B.LED The must green LED be ON. two positions A B. The be ON.must two positions A and B. The green LED must be ON. Received two positions A and B. The green LED must be ON. S300…F/G setting setting S300…F/G S300…F/G setting Not received a S300…F/G setting Position the sensors on opposite sides.toTurn the to maximum. Find the points whe S300…F/G setting opposite sides. Turn thetrimmer sensitivity trimmer maximum. Findwhere thetrimmer points where Position thePosition sensorsthe on sensors oppositeon sides. Turn the sensitivity to maximum. Find the sensitivity points Position the sensors on opposite sides. Turn the sensitivity trimmer maximum. Find theispoints where theto yellow LED (OUT) switched ON OFF inand both horizontal positions, and fix t Position the sensors on opposite sides. theLED sensitivity to maximum. Find the points where the yellow LED (OUT) isON switched ON OFF in both vertical andand horizontal positions, fix the theTurn yellow (OUT)trimmer is switched and OFF inand both vertical and horizontal positions, fix vertical the andand the yellow LED (OUT) is switched ON and OFF in both vertical and horizontal positions, and fix the sensor in theoperation centre these operation is obtained the yellow LED (OUT) is switched ON and in OFF in bothinbetween vertical and horizontal positions, and fixbetween the sensor the centre between these points. Optimum is points. obtained when switch both LEDs ON. when both LEDs switch O sensor the centre these points. Optimum isoperation obtained when bothOptimum LEDs ON. switch sensor in the centre between these points. Optimum operation is obtained when both LEDs switch ON. OUTPUTS If necessary, reduce sensitivity using the targets. trimmer, ordertotoIn detect very small targets. In order sensor in the centre between these points. Optimum operation is obtained when both ON. OUTPUTS If necessary, reduce sensitivity usingLEDs the trimmer, in ordervery to detect very small targets. order to OUTPUTS If necessary, reduce sensitivity using the trimmer, in switch order to detect small Ininorder necessary, reduce sensitivity using the trimmer, in order to small detect very small targets. In order to detailed above whilst progressively reducing the sensitivity. improve alignment, repeat procedure If necessary,Ifreduce sensitivity using the trimmer, in order tothe detect very targets. Inwhilst order to the improve alignment, repeat thedetailed procedure detailed above whilst progressively the sensitivity. improve alignment, repeat procedure above progressively reducing thereducing sensitivity. 4 improve alignment, repeat the procedure detailed above whilst progressively reducing the sensitivity. improve alignment, repeat the procedure detailed above whilst progressively reducing the sensitivity. S300…M setting S300…M setting S300…M setting S300…M setting Suppression distance setting on S300…M setting Suppression distance setting Suppression distance setting OFF Suppression distance setting Position to detect in front Turn ofrequired. thedistance sensor at distance the distance required. Turn distance adjustme Suppression distance setting a) Position objectintofront detect ina)front of the sensor at the distance Turn adjustment off a) Position object to detect of the sensor atobject the distance required. adjustment a) Position object to detect in sensor front ofatthe sensor at the distance required. Turn adjustment screw (ADJ) todistance minimum: yellow OFF. until Rotate clockwise direction until the yell a) Position object to detect in front of the distance required. distance adjustment (ADJ) toyellow minimum: yellow LED OFF. Rotate in LED adirection clockwise direction until in thea yellow screw (ADJ)screw tothe minimum: LEDTurn OFF. Rotate trimmer in atrimmer clockwise thetrimmer yellow (ADJ) to minimum: yellow LED trimmer in direction a LED clockwise direction until the yellow turns Object detection condition (pos.A). screw (ADJ) screw to minimum: yellow LEDLED OFF. Rotate trimmer in aObject clockwise untilON. the yellow LEDOFF. turnsRotate ON. detection condition (pos.A). turns ON. Object detection condition (pos.A). on LED turnsdetection ON. Object detection condition (pos.A). b)that Remove object andofis ensure that background is in frontOFF. of the sensor: yellow LED OFF. Rota LED turns ON. Object condition (pos.A). b) Remove object and the background in front of the the sensor: LED Rotate b) Remove object and that ensure the background is in front the sensor: yellow LED yellow OFF. Rotate T ensure T b) OFF T that T TRemove object and the ensure that thescrew front of the sensor: yellow LEDturns OFF. Rotate screw in ayellow clockwise direction until the yellow LED turns ON: background and ensure background isbackground in front of is theinuntil sensor: LED OFF. Rotate Toff b) Remove object in adirection clockwise direction until the LED ON: background detection condition (pos.B). detection condition (pos.B screw in a clockwise the yellow yellow LED turns ON: background detection condition (pos.B). T screw indirection a clockwise until theturns yellow LED turns ON:detection background detection condition (pos.B).direction until the trimmer reaches an intermediate point betwe c) Rotate screw in an anti-clockwise screw in a clockwise untildirection theRotate yellow LED background condition (pos.B). c) Rotate screw in an anti-clockwise direction until the trimmer an intermediate point between c) screw in anON: anti-clockwise direction until the trimmer reaches an reaches intermediate point between c) Rotate screw in an anti-clockwise direction untilreaches the trimmer reaches an point intermediate between A and C. Thepoint sensor isconditions. now ready conditions. to function correctly in stable conditions. c) Rotate screw in an anti-clockwise direction theC. trimmer an intermediate between position A and C. The sensor isto now ready to function correctly in stable positionuntil A and The sensor is now readyposition function correctly in stable on position A and C. The sensor is now ready to function correctly in stable conditions. T position in stable conditions. T ready to function correctly T is now OFF T T A andT C. The sensor T T (Target LIGHT ON INPUT LIGHT INPUT T Toff Retroreflective on R2 and R5 reflectors Polarized retroreflective on R2 and R5 reflectors DIAGNOSTIC FUNCTIONS DIAGNOSTIC FUNCTIONS DIAGNOSTIC FUNCTIONS DIAGNOSTIC FUNCTIONS DIAGNOSTIC FUNCTIONS ONT on TEST+ input (only S300-PA-2-G) TEST+ (only S300-PA-2-G) TEST+ input (only input S300-PA-2-G) T T input (only S300-PA-2-G) Toff T TEST+ input T TEST+ The TEST+ can bethe used tothat inhibit the emitter and verify that the system is correctly operating. (only S300-PA-2-G) be used toemitter inhibit theinput emitter and verify thecorrectly system is correctly operating. The TEST+ The inputTEST+ can beinput usedcan to inhibit the and verify that system is operating. TT ON on T Toff The can TEST+ input to can be used to inhibit theverify emitter thatisThe the system is correctly operating. TEST function if the input is connected to whereas a voltage between 10…30V, where The TEST+ input be used inhibit theTEST emitter and thatand theverify correctly The TEST function is activated if input the TEST+ inputisisactivated connected to aTEST+ voltage between 10…30V, The function is activated ifsystem the TEST+ isoperating. connected to a voltage between 10…30V, whereas The TEST functionif is activated ifinput the TEST+ input is toifathe voltage between whereas TEST+ is10…30V, connected to or it is is disactivated. not connected the function is disactivated. The TEST function is activated the TEST+ connected to connected a is voltage 10…30V, if is the TEST+ input connected or itinput iswhereas not connected function if the TEST+ input is connected to GNDbetween or ittois GND not connected the functionthe is GND disactivated. if the is TEST+ is connected GND or it is not connected function is disactivated. Activating TEST the output switches from ON tothe OFF (inoperation. light mode), testing the total operation. T input if the TEST+ GND or it istonot connected the function isthe disactivated. T input Activating the TEST the output switches from ONlight to OFF (in light mode), testing total Activating the TEST T the output switches from ON to the OFF (in mode), testing the total operation. T tothe T connected TEST output from(inON to mode), OFF (intesting light mode), testing the total operation. Activating theActivating TEST thethe output switches fromswitches ON to OFF light the total operation. OFF on off The sensors are NOT NOT safety devices, andinso MUST be used Theare sensors are NOT safety devices, and so MUST NOT the safety control of in the safety control The sensors NOT safety devices, and so MUST be used inbe theused safety control ofNOT are NOT safety devices, andNOT so MUST NOT be used incontrol the safety of machines where installed. www.datalogic.com The sensorsThe aresensors NOT safety devices, and so MUST be used in the safety of control the the machines where installed. the machines where installed. the machines where installed. the machines where installed. OFF T on Toff T T DECLARATION OF CONFORMITY DECLARATION OF CONFORMITY DECLARATION OF CONFORMITY DECLARATION OF CONFORMITYWe Datalogic Automation declare under our sole responsibility these DECLARATION OF CONFORMITY under ourAutomation sole responsibility that these products are the products are conform to t We Datalogic Automation declare under We our Datalogic sole responsibility thatdeclare these products are conform to conform the that to Datalogicdeclare Automation declare under our sole responsibility that these arethe conform to the and successive amendments. We DatalogicWe Automation under our sole responsibility that these products are products conform to 2004/108/CE and amendments. successive 2004/108/CE amendments. 2004/108/CE and successive T T T 2004/108/CE andamendments. successive amendments. 2004/108/CE and successive Maxi Sensors - S300 PA 18% Grey 90% White Diffused proximity 18% Grey Through beam 90% White 6% Black 90% White 18% Grey 90% White Background suppression BGS - White/Grey and White/Black Difference MODEL SELECTION AND ORDER INFORMATION OPTIC FUNCTION Retroreflective (IR LED 880 nm) Polarized retroreflective (red LED 660 nm) Diffused proximity (IR LED 940 nm) POWER SUPPLY 12…30 Vdc 24...240 Vac/24…60 Vdc 12…30 Vdc 24...240 Vac/24…60 Vdc 12…30 Vdc 24...240 Vac/24…60 Vdc OUTPUT NPN/PNP Relay NPN/PNP Relay NPN/PNP Relay 12…30 Vdc NPN/PNP 24...240 Vac/24…60 Vdc Relay Through beam receiver Through beam emitter (IR LED 880 nm) Background suppression (IR LED 880 nm) 12…30 Vdc 24...240 Vac/24…60 Vdc 12…30 Vdc 24...240 Vac/24…60 Vdc NPN/PNP Relay SETTING MODEL ORDER No. Sensitivity trimmer and D/L dip-switch S300-PA-2-A01-OC 951451500 Timing and sensitivity trimmers, D/L dip-switch S300-PA-2-A06-OC 951451510 Sensitivity trimmer and D/L dip-switch S300-PA-1-A01-RX 951451480 Timing and sensitivity trimmers, D/L dip-switch S300-PA-1-A06-RX 951451490 Sensitivity trimmer and D/L dip-switch S300-PA-2-B01-OC 951451540 Timing and sensitivity trimmers, D/L dip-switch S300-PA-2-B06-OC 951451550 Sensitivity trimmer and D/L dip-switch S300-PA-1-B01-RX 951451520 Timing and sensitivity trimmers, D/L dip-switch S300-PA-1-B06-RX 951451530 Sensitivity trimmer D/L dip-switch S300-PA-2-C01-OC 951451420 Timing and sensitivity trimmers, D/L dip-switch S300-PA-2-C06-OC 951451430 Sensitivity trimmer and D/L dip-switch S300-PA-1-C01-RX 951451400 Timing and sensitivity trimmers, D/L dip-switch S300-PA-1-C06-RX 951451410 Sensitivity trimmer and D/L dip-switch S300-PA-2-F01-OC 951451600 Timing and sensitivity trimmers, D/L dip-switch S300-PA-2-F06-OC 951451610 Sensitivity trimmer and D/L dip-switch S300-PA-1-F01-RX 951451580 Timing and sensitivity trimmers, D/L dip-switch S300-PA-1-F06-RX 951451590 - S300-PA-2-G00-EX 951451570 S300-PA-1-G00-EX 951451560 7-turns distance adjustment trimmer and /L dip-switch S300-PA-2-M01-OC 951451460 Timing and 7-turns distance adj. trimmers, D/L dip-switch S300-PA-2-M06-OC 951451470 7-turns distance adjustment trimmer and D/L dip-switch S300-PA-1-M01-RX 951451440 Timing and 7-turns distance adj. trimmers, D/L dip-switch S300-PA-1-M06-RX 951451450 www.datalogic.com Maxi Sensors - S300 PA ACCESSORIES ST-511 MODEL DESCRIPTION ORDER No. ST-511 mounting bracket 95ACC2810 www.datalogic.com Maxi Sensors - S300 PA Rev. 01, 07/2016 www.datalogic.com