Lean Construction

advertisement

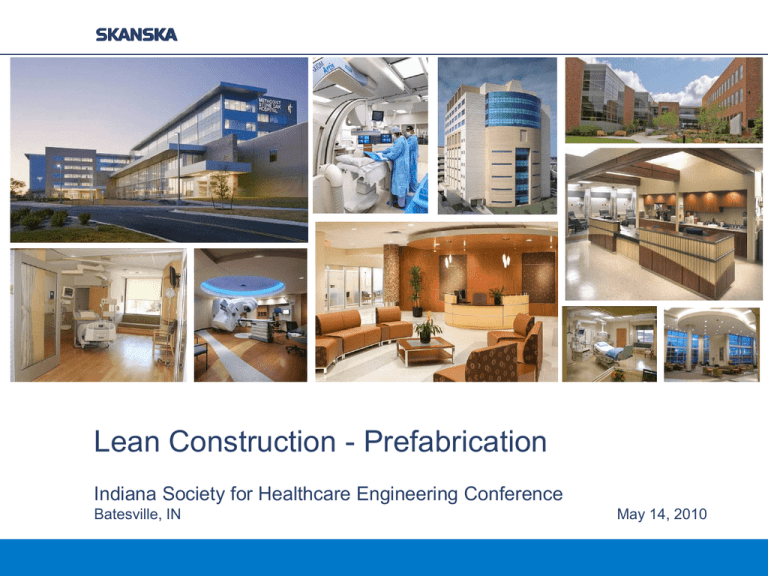

Lean Construction - Prefabrication Indiana Society for Healthcare Engineering Conference Batesville, IN May 14, 2010 Agenda Skanska Overview Principles of Lean Vehicles of Change Contractual Building Skanska Overview − Skanska AB – one of the world’s leading construction groups − Skanska USA - $4.0 billion in revenues in 2009 − 33 national offices offer local services with the benefit of national resources − Approximately 8,200 employees nationwide − Among most financially stable and best capitalized construction firms in the world − Market sectors include: − − − − − Healthcare Science and technology Government Education Corporate commercial 3 Skanska Overview − Healthcare is Skanska’s primary market comprising 30 percent of business − Healthcare Center of Excellence brings national resources and expertise − Currently $4 billion healthcare projects in U.S. − Built nation’s first LEED Gold Certified Hospital – Providence Newberg Medical Center Providence Newberg Medical Center Consistently ranked among elite construction firms in annual rankings by Engineering News-Record and Modern Healthcare 4 Why Lean? Waste vs. Productivity $15.8B lost annually due to fragmentation $10.8B Owners / Operators $1.8B GC’s US Dept of Commerce Bureau of Labor Statistics $2.2B Trade industry $1.2B Architects / Engineers Symptoms of a Broken System − Numerous RFIs − Changing cast of players − Re-design − Unmet expectations − Delays − Productivity losses − Cost surprises and change orders − Claims and disputes − Compromised scope to "stay in budget" Reaching a New Frontier Leadership, Planning and Management Traditional Leadership Dictates direction Planning Partitioned by disciplines and is linear. Predictive and generally fixed, setting parameters for management Management Controls are inflexible, autocratic processes are fixed and measures are isolated and historical Lean Facilitates collaborative direction Collaborative, project based and seeks to integrate efforts to eliminate negative iterations. Learns as project evolves Develops a “network of commitments” to implement plan, evolves intelligence, measures are integrated and proactive Lean Principles − Collaborate – really collaborate − Early engagement of team members − Target Value Design − Last Planner – all parties involved in the schedule − Elimination of waste and duplicate activities − Implement the 5 S’s − Continuous feedback and learning Follow the 5 S’s Sort Separate the necessary from the unnecessary Simplify Neatly arrange and identify items Sweep Routine inspections to keep workplace in perfect order Standardize Document methods and formalize agreements Self Discipline Hold team accountable to maintain agreed upon standards Project Delivery Typical Project Arrangement Owner Reinforced by provisions of AIA and AGC “standard“ contracts. Parties act against each others' interests Designer Contractor This relationship has become increasingly ambiguous Integrated Project Delivery (IPD) − Integrates people, systems, business structures and practices into a process that collaboratively harnesses the talents and insights of all participants to reduce waste and optimize efficiency through all phases of design, fabrication and construction. − IPD is the process; BIM and Last Planner are the collaborative tools One Contract Building Prefabrication Common Misconceptions − Lesser Quality − Redundant Design Needed − Compromises Design Creativity SEA Project December 2009 Value to User Groups − Cost Avoidance − Open Doors to Facility Faster − User Input, Review and Approvals − Fewer changes − Fewer Inconveniences − Minimal disruption to ongoing operations − Less Manpower i.e. decrease in parking needed, safety issues, etc. − Collaborative Team Effort Southeast Addition Project Southeast Addition Project 16 American College of Healthcare Executives Southeast Addition Project − 484,000 Square Feet − 12 Stories (2 shelled for future growth) − 178 Private Rooms − Campus Transformation Southeast Addition Project December 2009 Patient Room Design − 100% Private Rooms − Standardization of Spaces for Patients/Staff − Acuity Adaptable Patient Rooms − Same Handed (Repetitive) Design − Designed by Caregivers Patient Room Rendering Understanding Prefabrication − Prefabrication Video Prefabrication Application − 5 Patient Floors − 3 Wings Per Floor − Corridor of each wing is being prefabricated in a warehouse 2 miles from the project, in 3 phases − Corridor rack modules − Bathroom pods − Patient room headwalls/footwalls Prefabricated Corridor Racks Prefabricated Corridor Racks Prefabricated Corridor Racks Transportation from Warehouse to Jobsite Prefabricated Corridor Racks Installation Patient Rooms Headwall/Footwall & Bathroom Bathroom Pods/Headwalls Construction Benefits − Improved Safety & Quality − Cost Savings − Reduced Manpower Peak − Reduced Waste − Seismic Benefits − Increased Above Ceiling Accessibility Improved Safety − Working on the ground instead of height Replacement Hospital Square Feet Man Hours Worked On site Workers LTIR with Patient Tower – Tennessee 625,000 1,005,874 LTIR Industry 715 0.6 Average 1.9* New Hospital Project – Tennessee Square Feet 225,000 Man Hours Worked 768,529 On Site Workers 520 LTIR 0.26 Southeast Addition Project – Dayton, OH Square Feet 485,000 Man Hours Worked 446,195 On Site Workers 310 LTIR 0 *OSHA Statistics from AGC of America 2007 Reports Safely working on corridor racks Improved Quality − Controlled Environment − Cleaner – Infection Control − Materials Ordered to Specific Length − Ductwork Installation − Fewer Connections − Eliminates cross connections of piping systems Cleanliness of Warehouse Cost Savings − Anticipate Savings up to 1-2% of Construction Cost − Earlier Revenue Generation for MVH − 5-10% Schedule Savings SEA Project December 2009 Reduced Manpower Peak Estimated vs. Actual Manpower (Mechanical, Electrical, Plumbing) Reduced Waste Greenfield Hospital – Ohio Square Feet 544,443 Waste Removal Cost $138,970 New Hospital Project – Florida Square Feet 423,000 Waste Removal Cost $200,006 New Hospital Project – Florida Square Feet 480,000 Waste Removal Cost $490,083 Southeast Addition Project – Dayton, OH Square Feet 485,000 Estimated Waste Removal Cost $91,000 Other Benefits − Seismic Benefits − − − − Comprehensive Seismic Design vs. Traditional Seismic Bracing Smaller Quantity Needed for Seismic Materials Labor Installation Savings Reduced Cost for Future Renovations − Increased Above Ceiling Accessibility − Improves Ongoing Maintenance for Hospital Systems − Flexibility for Future Additions/Renovations − Organization Accommodates Facility Maintenance Questions? Andrew Quirk Senior VP Skanska 615-969-3708 andrew.quirk@skanska.com