Dr. Gernot Klotz: Is Europe`s approach to innovation fit for purpose?

advertisement

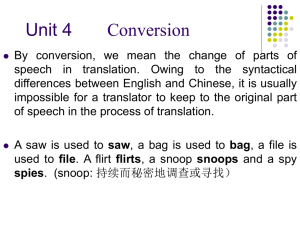

Fostering EU Competence and Competitiveness Through Innovation Industrial Technologies 2012, June 19 Dr. Gernot Klotz Executive Director Cefic Research & Innovation gkl@cefic.be Strengths of Europe • • • • • 1st class research landscape Network of big companies and SMEs Well developed markets (common market) Proximity of knowledge and industrial value chain Ability to deal with complexity Need for a well- articulated European innovation model that: builds on own strengths keeps / create / bring back value to Europe in a quite short timeframe EU Innovation Union: Visible leading role for Chemical Industry Bring policy and business models closer together Current public model Policy input Business model end user sector end user sector Supplier 1 Supplier 1 Supplier 2 Supplier 2 Materials Policy input Supplier n Supplier n Chemical industry Policy input Advanced Processes Chemical industry Policy input Value chain “Innovation chain” : from research to innovation up to competitive manufacturing “Value chain” : cooperation of the relevant business sectors (from raw material to final product) to ensure delivery of products and processes 6 Horizon2020 - what we like • EU wide approach and significant increase of funding volume • Focus on output rather than being descriptive • Coordination of programmes through bridging actions • Inclusion of piloting and scale up • Distinct funding line for Key enabling technologies • Focus on excellence; structural improvements n cohesion policy Horizon2020 – what needs strengthening • Simultanious stimulation of value chain • Research and innovation follow different driver – need for fitness check of instruments for innovation (e.g. timelines) • New model for PPP on innovation rather than existing ones for research only (more risk taking) • EU strength is network of big and SMEs – rules for participation to promote networking (challenge also for structural funds) • Improved role for „revised“ EU Technology Platforms (researchinnovation- education) in Innovation Union • Benchmark against global performances of regions Financial instruments European Innovation Partnerships (EIPs) Flagship Initiatives Europe 2020 Youth on the move A digital agenda for EU Healthy ageing Horizon 2020 Resource efficient Europe Raw Materials Innovation Union Water efficiency European Innvestment Bank Smart Cities An industrial policy for the globalisation era Smart Mobility An agenda for new skills and jobs Agricultural sustainability Structural Funds Risk Capital European platform against poverty Key enabling technologies National Funding Jungle of EU Public Support today Critical mass? - Outreach of EU Technology and Innovation Platform SusChem 12 Process Industries in the Value Chain Raw Materials Process Industry: Chemical, biochemical, and physical transformation and formulation of raw materials using continuous and batch processes into Materials with new properties and functionalities Discrete Manufacturing: Components & Products PPP Proposal SPIRE Sustainable Process Industry European Industrial Competitiveness through Resource and Energy Efficiency PPP – Value chain alignment OIL 1 Exploitation Oil / gas extraction 2 Basic Components Crackers 3 Enhanced Processing 4 Discrete Manuf. Intens. Proc. Industrial Agriculture KBBE METALS/ CRM Mining EIP MINERALS Bio Refinery Industrial Biotechn. Base Metals Hybrids Factory of the Future existing CROPS 5 Consumer Products Alliance for materials Photonics Green cars Energy Efficient Building Value chain position Market PPP’s 15 Biobased feedstock Ind Biotech Adv Manuf Bio-based monomer Adv Manuf Adv Material Polymer Adv Manuf Advanced material VC Automotive Electronic … Demonstration phase : 3 years , 50M New Adv Material lighweight advanced Adv material Manuf (pilot) Adv Manuf Adv Material Prototype structural part(pilot) Adv Manuf Adv Material Demonstration phase : 5 years , 30M Prototype structural part(pilot) VC Greener combustion or electric cars Nanotech Adv Material lighweight advanced material Adv Manuf Adv Material Prototype subsyste m Adv Manuf Pilot turbine Adv µ n-electronic Material VC Operation experience 5-8 years Demonstration phase : 5-8 years 50M – 100M Nanotech Adv Material New multifunctional materials Adv Manuf More efficient wind turbine New photovoltaic system through new process VC Broader deployment of photovoltaic energy Demonstration : 5 years , 20M Nanotech Adv Material Specific materials µ n-electronic New device Adv Material Energy storage pilot Demonstration phase : 5 years , 80 - 100M VC Future generation of energy storage for wind and photovolatic energy Value chains types KET Consumer Type A Type B Different needs and characteristics: Local cluster /trans-national Major needs late in the value chain /earlier in the value chain Value added more upfront / later Financing needs 18 Report http://www.cefic.be/Files/Publications/Skills-forInnovation-in-the-European-Chemical-Industry.pdf 8 Take home messages • Research ≠ innovation, specific EU Innovation model needed • Innovation in industry and public bodies especially in mindset, not only more funds • Innovative ways of working together – cross border, more public-private commitments • Innovation along value chain is key for success in EU • Activate all resources also regional, but adequate complexity • ‘Show me’ rather than ‘tell me’ as policy guideline • Strengthening existing & new industries for growth and jobs • The EU Chemical industry, a world leading sector, is committed to drive growth and jobs through innovation in Europe 20