Administrative Controls

advertisement

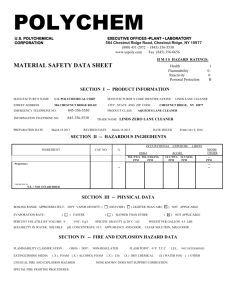

Ergonomics A science that focuses on human capabilities and limitations in the design of work tasks, workstations, tools and equipment. PRESENTED BY: Joan M. Spencer Compliance Assistance Specialist Tampa Area Office 813-626-1177 Costs to the Employer • • • • • • Insurance Premiums Medical Costs Absenteeism/Turnover Re-Training Decrease in Production Decrease in Quality Costs to the Employees • • • • • Pain/Suffering Stress Loss of ability to work Loss of wages Loss of ability to enjoy life Indicators of Need • • • • • • Employee Generated Change Manual Material Handling Seasonal Hiring Downsizing Over-time Incentive Programs Indicators of Need • • • • • • Complaints Absenteeism Turnover Accident Trends Poor Quality Decrease in Production • 2001, Congress passed, and the President signed, Senate Joint Resolution 6, which rescinded the original ergonomics rule, and under the Congressional Review Act, prohibits the agency from issuing a rule that is substantially the same as the former one. OSHA Enforcement Program • OSHA assesses MSD-related issues in complaints, referrals, and targeted inspections. • Issue General Duty Clause citations or hazard alert letters for ergonomics hazards where appropriate. • Conduct follow-up inspections or investigations within 12 months of certain employers who receive ergonomic hazard alert letters. Full Ergonomics Program • Management leadership and employee participation • Hazard information and reporting • Job hazard analysis and control • Training • MSD management—that includes taking care of the injured employee • Program evaluation Risk Factors • • • • • • Force Posture Repetition Temperature Vibration Pressure Points Job Factors Physical demands of job Force, repetition, postures, duration, contact stress Workstation layout and space Reaches, heights, seating, floor surface, contact stress Equipment used and objects handled Size, shape, weight, weight distribution, handle and grasp surfaces, vibration Environmental conditions Cold, heat, glare Work organization Work-recovery cycles, work rate, task variability Hazard Identification & Information • Is there a method for employee reporting of signs, symptoms, hazards and recommendations • OSHA Form 300 • Medical Records • Insurance Records • Safety Records • Personnel Records Job Hazard Analysis • Include each of or a representative sample of employees in the problem job • Expand JHA to similar jobs (if comprehensive) • Question employees on • experience signs and symptoms • difficulties of performing physical • work activities of job • which activities they associate with any problem Job Hazard Analysis and Control • Ask employees for recommendations • Identify, evaluate and suggest (implement) feasible control measures • Do you track progress in eliminating or materially reducing the MSD • Do you identify and evaluate MSD hazards when you change, design or purchase equipment or processes in problem jobs Tools OSHA May Use for Evaluation NIOSH Lifting Equation RWL = LC X HM X VM X DM X AM X FM X CM where LC is the load constant (23 kg), •HM, the "Horizontal Multiplier" factor •VM, the "Vertical Multiplier" factor •DM, the "Distance Multiplier" factor •FM, the "Frequency Multiplier" factor •AM, the "Asymmetric Multiplier“ factor •CM, the "Coupling Multiplier" factor •RWL, the "Recommended Weight Limit http://www.ccohs.ca/oshanswers/ergonomics/niosh/calculating_rwl.html Controls Engineering, Administrative, and/or Work practices Personal protective equipment Engineering Controls • Preferred method • Act on the source of the hazard • Control without relying on employee to take self-protective action or intervention • Changing, modifying or redesigning workstations tools facilities equipment materials processes Engineering Controls • • • • • • • Mechanical lifting hoists Tool design Automation of work Work station design Use of handles Repackage for weight and size Padding/absorption systems Engineering Controls: Avoid low or high reaches Engineering Controls: Hoist, lifters Engineering Controls: Powered Equipment Engineering Controls: Use correct tools: Sand rammer in foundry was modified with “home-made” vibration absorbing rings instead of original manufacturer’s equipment. Engineering Controls: Handles Engineering Controls: Automation Manually handling packaged product. Company is in the process of installing automatic filling & conveyor system Engineering Controls: Workstation Design Insufficient work space to accommodate mouse/pointing device; chair has little adjustability. Administrative Controls Alternate heavy tasks with light tasks. Provide variety in jobs to eliminate or reduce repetition (i.e., overuse of the same muscle groups). Adjust work schedules, work pace, or work practices. Provide recovery time (e.g., short rest breaks). Modify work practices so that workers perform work within their power zone (i.e., above the knees, below the shoulders, and close to the body). Rotate workers through jobs that use different muscles, body parts, or postures. Administrative Controls: Use your power zone Use a Lifter Raise the Worker Raise or Lower the Work Surface Tilt the Container Administrative Controls: Employees involved in manually turning dough to form pastries. Company had instituted a rotation policy to other areas within department. Administrative Controls: Employees involved in manually handling products. Two person lift with handles. Work Practice Controls: Training on body mechanics provided to reduce twisting at the waist. Also suggested using carts of same height as work area to reduce elevation changes. PPE Interim control device Worn or used by employee Provide in a variety of sizes Should not contribute to extreme postures and excessive forces. Examples include: gloves or knee pads “Braces, splints, back belts, and other similar devices are not PPE.” Personal Protective Equipment: Gloves Gripping gloves. Outreach and Assistance: • OSHA provides tools to help workplaces reduce and prevent ergonomic injuries: • Provide expertise to assist businesses and workers • Support programs through training grants, curriculum development and other means • Design compliance assistance tools, new partnerships and recognition programs • Encourage others to develop best practices Industry Specific Guidelines:1 • • • • • Meat Packing Guidelines Nursing Homes Retail Grocery Stores Poultry Processing Shipyards 1 The guidelines are not new standards or regulations and do not create any new OSHA duties for employers. An employer's failure to implement a guideline is, therefore, not a violation, or evidence of a violation of the general duty clause of the OSH Act Additional Information www.osha.gov www.cdc.gov/niosh/homepage.html